A method and device for measuring and calculating the exit angle of Tamm coupling based on excitation registration

An exit angle and registration technology, which is used in measurement devices, material excitation analysis, and optical devices, etc., can solve the problems of low efficiency, difficult to identify the exit angle, and low universality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing of description, the present invention will be further described.

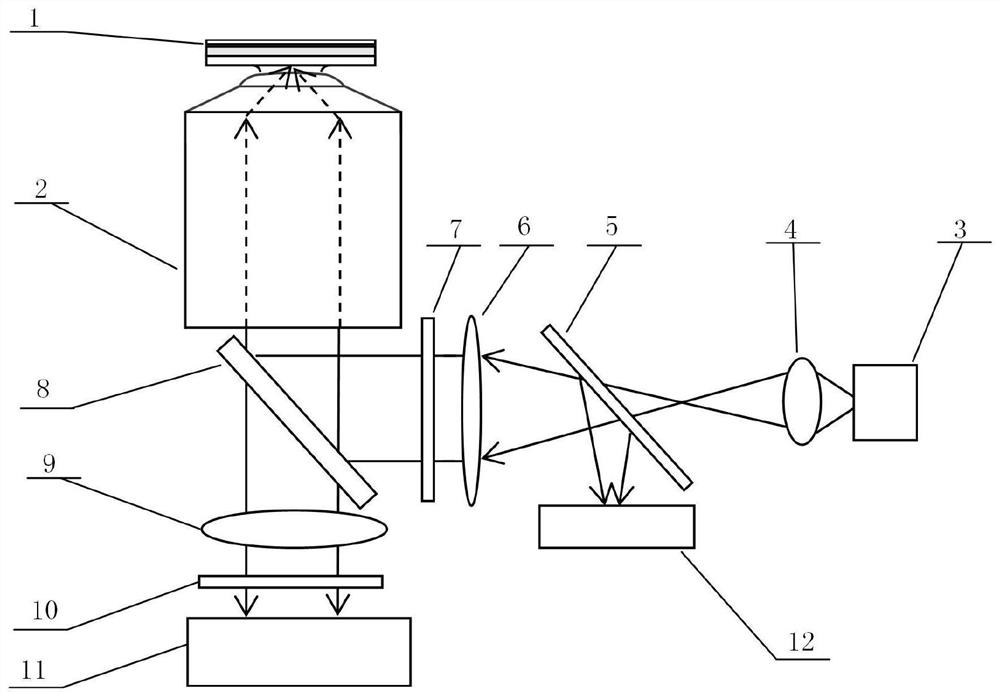

[0030] combine figure 1 , a Tam coupling exit angle measurement device based on excitation registration, said device includes a Tam structure 1, an oil immersion objective lens 2, a white light source 3, a converging convex lens 4, a beam splitter 5, a collimating convex lens 6, a short-wave Narrowband filter 7, dichroic mirror 8, imaging lens 9, long-wave narrowband filter 10, fluorescent CCD image sensor 11, white light CCD image sensor 12, the Tam structure 1, oil immersion objective lens 2, dichroic mirror 8 , an imaging lens 9, a long-wave narrow-band filter 10, and a fluorescent CCD image sensor 11 are arranged in sequence, the white light source 3, a focusing convex lens 4, a beam splitter 5, a collimating convex lens 6, a short-wave narrow-band filter 7, and a dichroic mirror 8 are arranged in sequence, the Tam structure 1 is located on the oil imme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com