Pigment dispersion composition for black matrix and pigment dispersion resist composition for black matrix containing the same

A pigment dispersant and pigment dispersing technology, which is applied in photosensitive materials used in optomechanical equipment, photoplate making process of patterned surface, optics, etc., can solve the problem that the unexposed part cannot be completely removed, the adhesion is reduced, and the development is confirmed to be terminated It achieves the effect of excellent optical density, low reflectivity, and excellent dispersion stability due to problems such as timing difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

[0123]

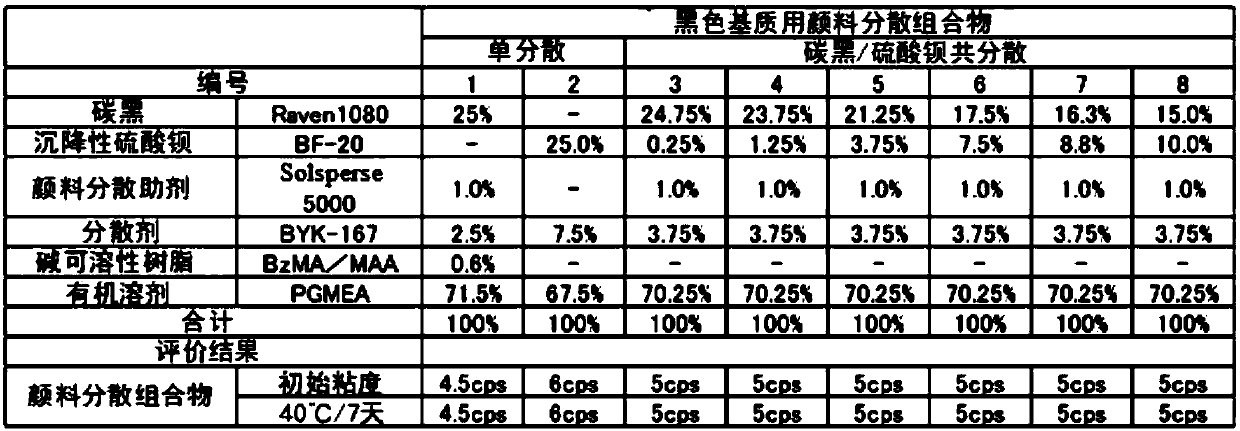

[0124] In order to become the combination of Table 1 (the usage-amount of each material in Table 1 is mass %), various materials were mixed and kneaded with the bead mill, and the pigment dispersion composition for black matrices of Nos. 1-8 was prepared.

[0125]

[0126] Using a high-speed mixer, uniformly mix the pigment dispersion compositions for each black matrix No. 1 to No. 8 with other materials to form the composition of Table 2 (the usage amount of each material in Table 2 is mass %), and then use a pore diameter of 0.5 μm Filtration was performed with a filter to obtain the pigment-dispersed resist compositions for black matrices of Examples 1-5 and Comparative Examples 1-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com