Packaging structure and packaging method of LED shoe light

A packaging method and packaging structure technology are applied in lighting devices, semiconductor devices of light-emitting elements, lighting and heating equipment, etc., which can solve the problems of reducing the luminous effect of shoe lamps, affecting the heat dissipation and light transmission of LED lamps, and achieving a simple packaging process. Fast, easy to operate, good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

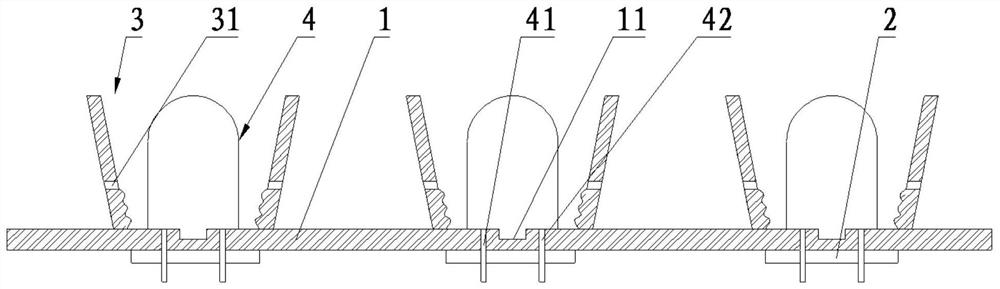

[0036] A packaging structure for LED shoe lights, characterized in that it includes a transparent substrate, a plurality of PCB boards and LED lamp beads arranged on the bottom surface of the transparent substrate, a plurality of transparent trapezoidal platforms are arranged on the transparent substrate, and the transparent trapezoidal The number of platforms is the same as the number of PCB boards, the two ends of the transparent trapezoidal platform are open, the narrow end of the transparent trapezoidal platform is connected to the upper bottom surface of the transparent substrate, and the side wall of the transparent trapezoidal platform is set at 1 / 3 from the bottom. There are several through holes, and the inner wall of the side wall of the transparent trapezoidal table is evenly provided with point-like protrusions on the surface at a distance of 1 / 3 from the bottom;

[0037] A positive plate hole and a negative plate hole are provided on the PCB, and a positive pole ja...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com