Single fuel cell and fuel cell stack

A technology of fuel cells and monomers, applied in the directions of fuel cells, circuits, electrical components, etc., can solve the problems of deformation and displacement of the insulating frame, affecting the performance of the battery, etc., and achieve the effect of simplifying the assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

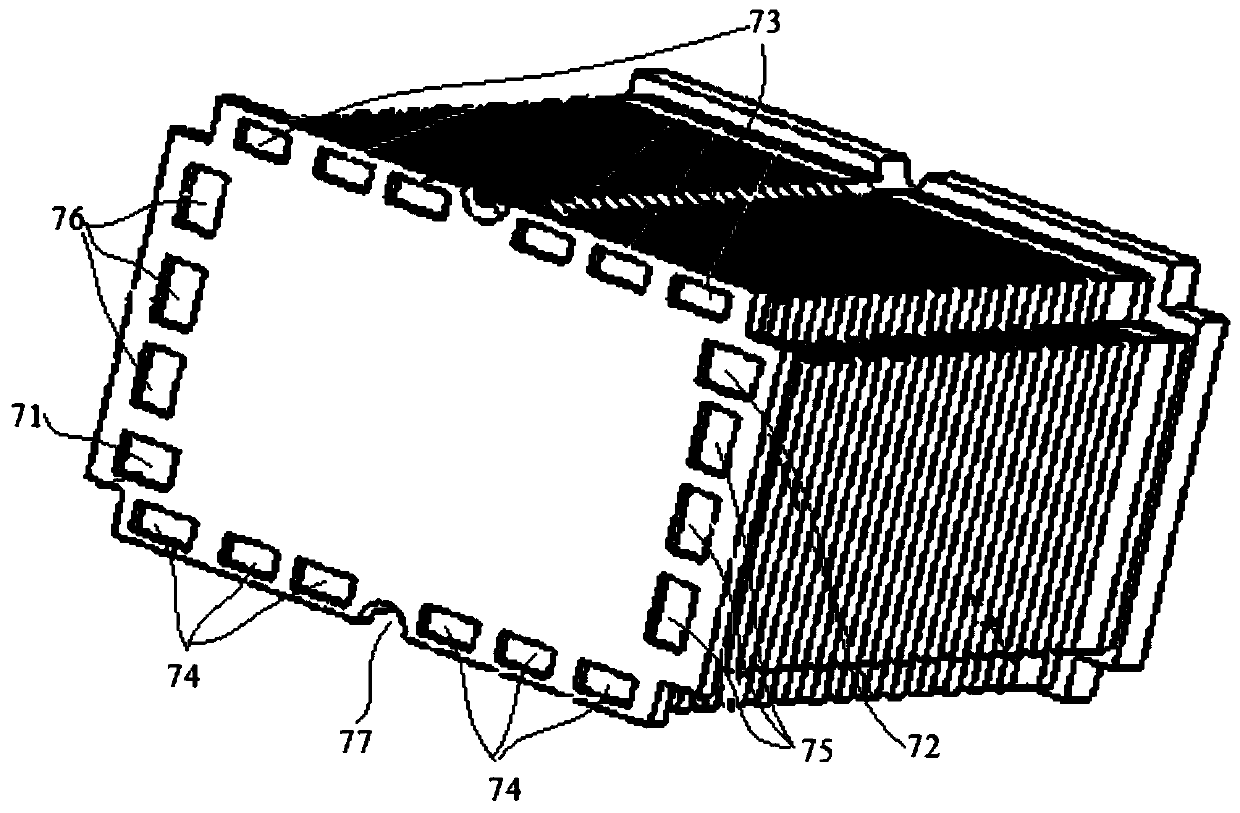

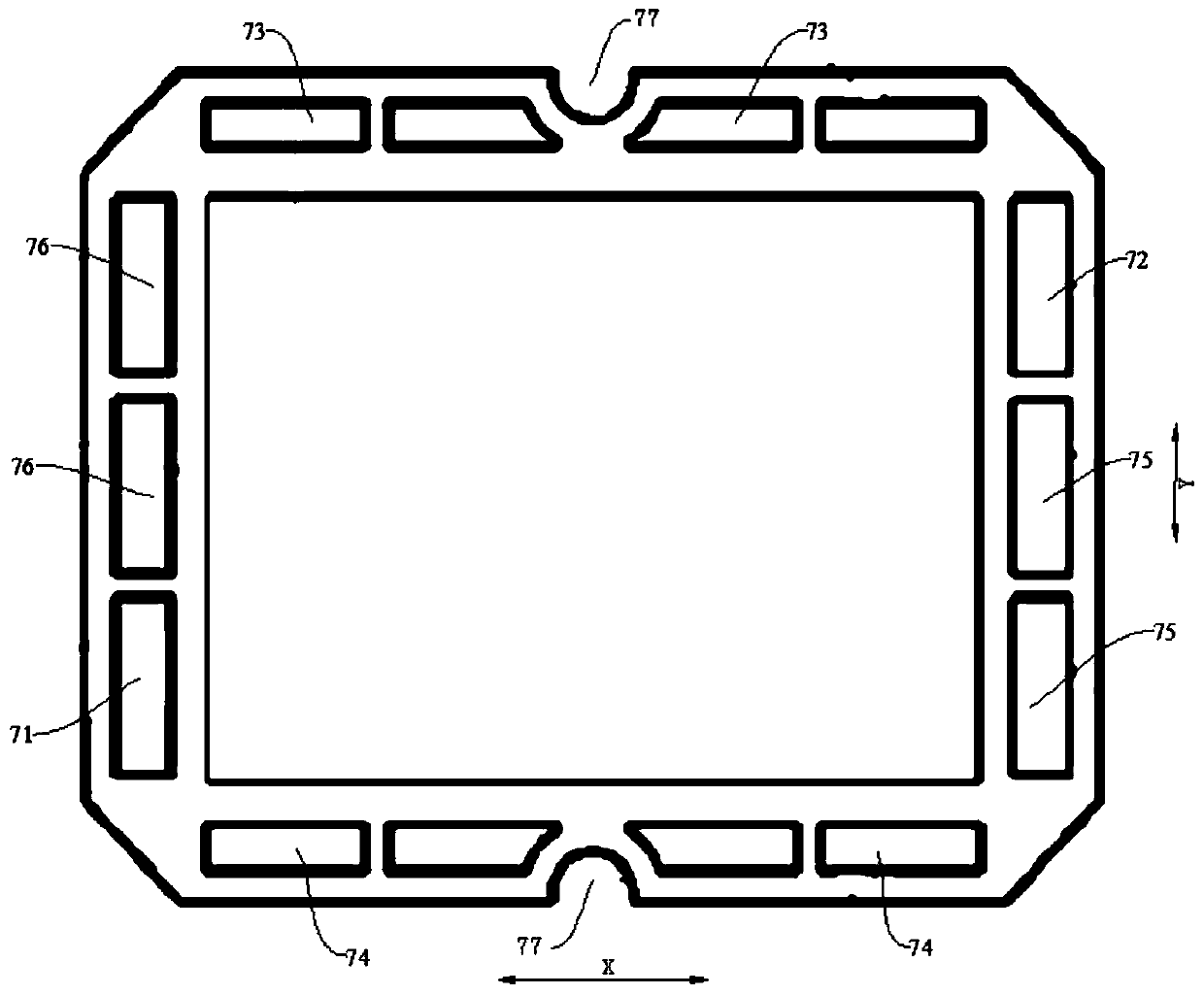

[0051] Refer below Figure 1-Figure 22 A fuel cell separator according to an embodiment of the present invention is described.

[0052] like Figure 1-Figure 22 As shown, a fuel cell separator according to one embodiment of the present invention includes an anode plate 10 and a cathode plate 20 .

[0053] Among them, such as Figure 21 As shown, the first side of the anode plate 10 is provided with an anode flow channel 111, at least part of the anode flow channel 111 extends along the first direction, preferably, the main part of the anode flow channel 111 extends along the first direction.

[0054] like Figure 22 As shown, the first side of the cathode plate 20 is provided with a cathode flow channel 211, at least part of the cathode flow channel 211 extends along the second direction, at least part of the cathode flow channel 211 extends along the second direction, preferably, the cathode flow channel 211 The body portion extends along the second direction.

[0055] The...

Embodiment 2

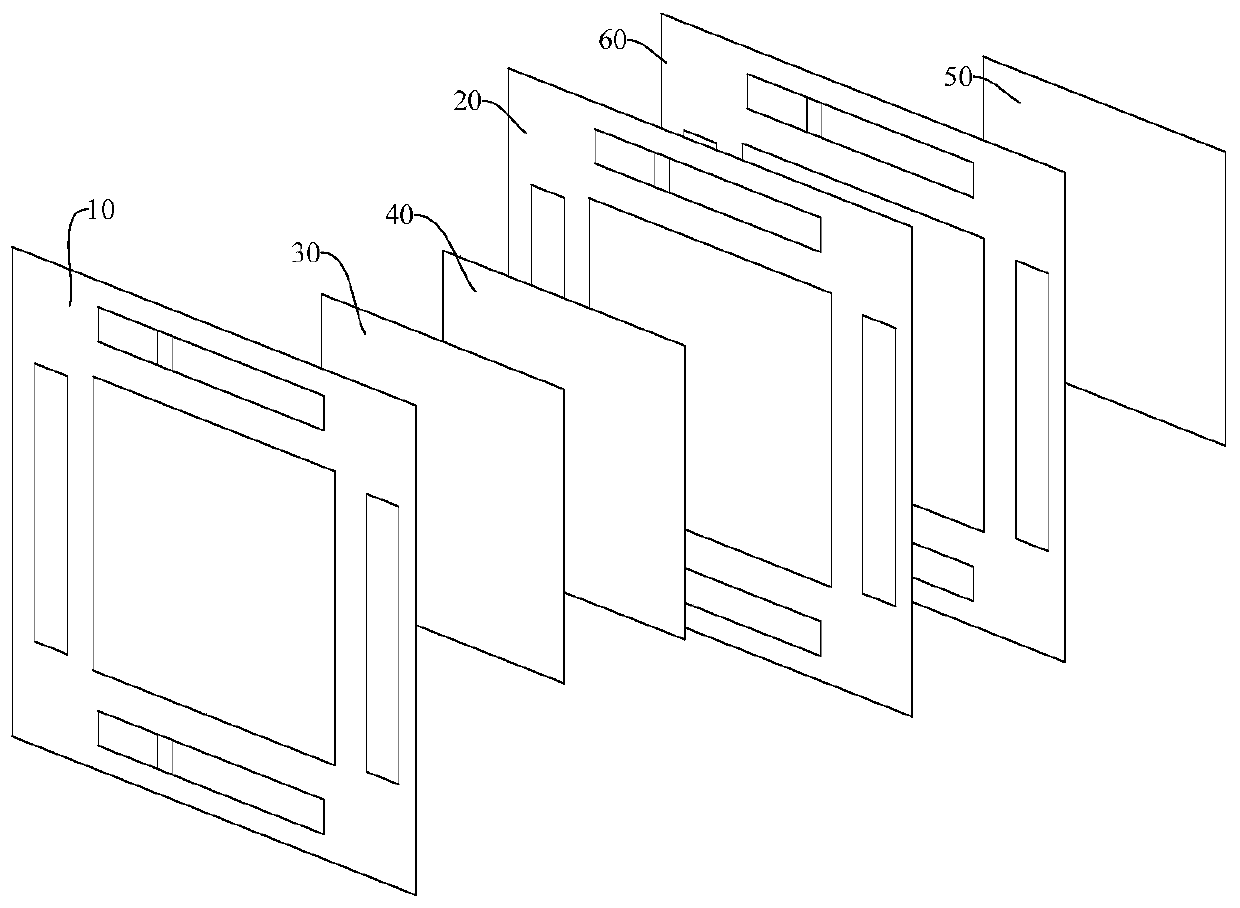

[0084] Refer below figure 2 , Figure 4-Figure 20 A fuel cell separator according to an embodiment of the present invention is described.

[0085] like figure 2 , Figure 4-Figure 20 As shown, a fuel cell separator according to one embodiment of the present invention includes an anode plate 10 , a cathode plate 20 and a grid plate 60 .

[0086] Wherein, the first side of the anode reaction zone 11 and the first side of the cathode reaction zone 21 are used to connect the membrane electrode assembly 30 of the fuel cell stack.

[0087] The grid 60 is interposed between the second side of the anode edge region 12 and the second side of the cathode edge region 22 , and the grid 60 is connected to both the anode edge region 12 and the cathode edge region 22 .

[0088] For example, the anode reaction area 11 may be rectangular, the anode edge area 12 may be a rectangular frame, the cathode reaction area 21 may be rectangular, the cathode edge area 22 may be a rectangular frame...

Embodiment 3

[0107] Refer below figure 2 , Figure 9-Figure 20 A fuel cell separator according to an embodiment of the present invention is described.

[0108] like figure 2 , Figure 9-Figure 18 As shown, a fuel cell separator according to an embodiment of the present invention includes an anode plate 10 , a cathode plate 20 and a gas circuit assembly 40 .

[0109] Wherein, the first side of the anode plate 10 is provided with an anode flow channel 111, the first side of the cathode plate 20 is provided with a cathode flow channel 211, the second side of the cathode plate 20 is opposite to the second side of the anode plate 10, and the gas path The component 40 is arranged on the first side of the cathode plate 20, and the gas path component 40 covers at least a part of the cathode flow channel 211, and the gas path component 40 can completely cover the cathode flow channel 211, or only cover a part of the cathode flow channel 211.

[0110] The gas circuit assembly 40 can meet the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com