Frame outer corner chamfering device

A corner rounding and frame technology is applied in the field of frame outer corner rounding devices, which can solve the problem of inability to process high-precision aluminum alloy door frames, and achieve the effects of reducing operating strength, accurate positioning, and ensuring accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

[0026] The invention provides a frame outer corner rounding device.

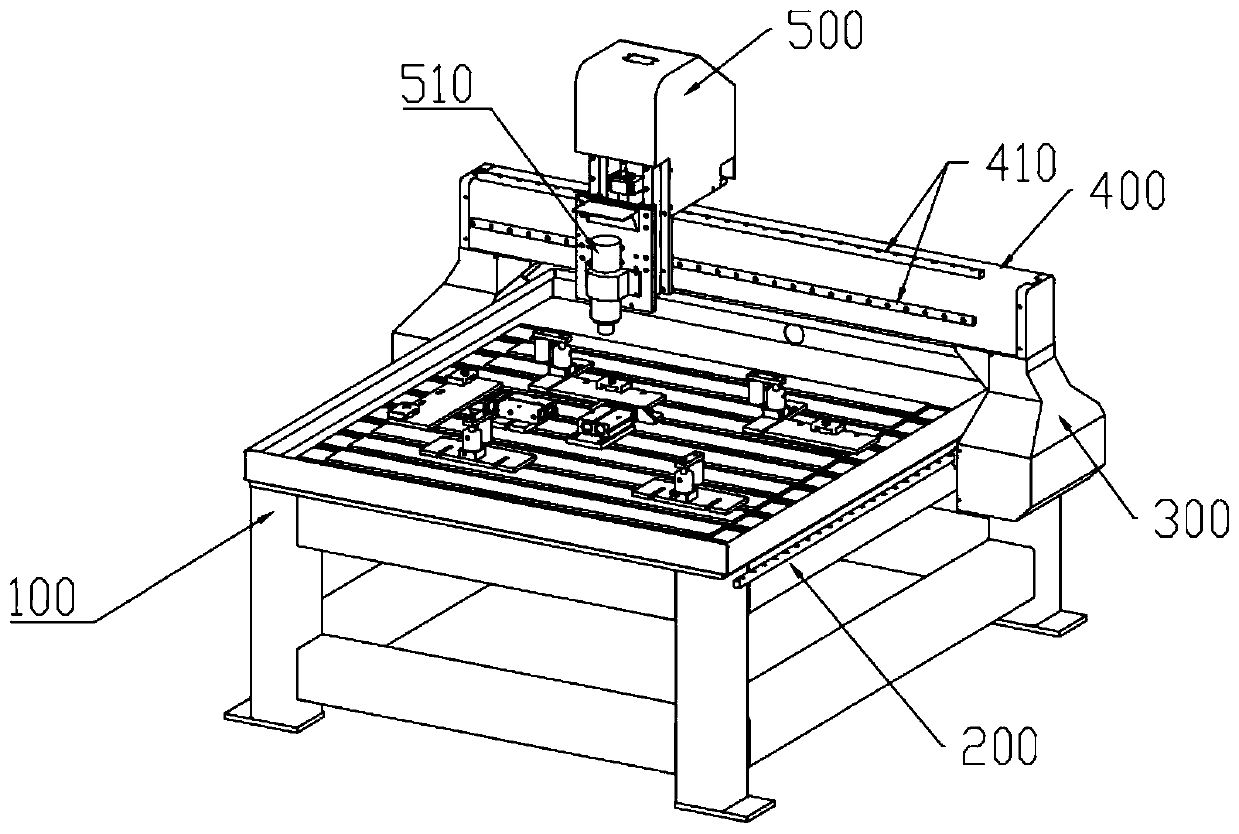

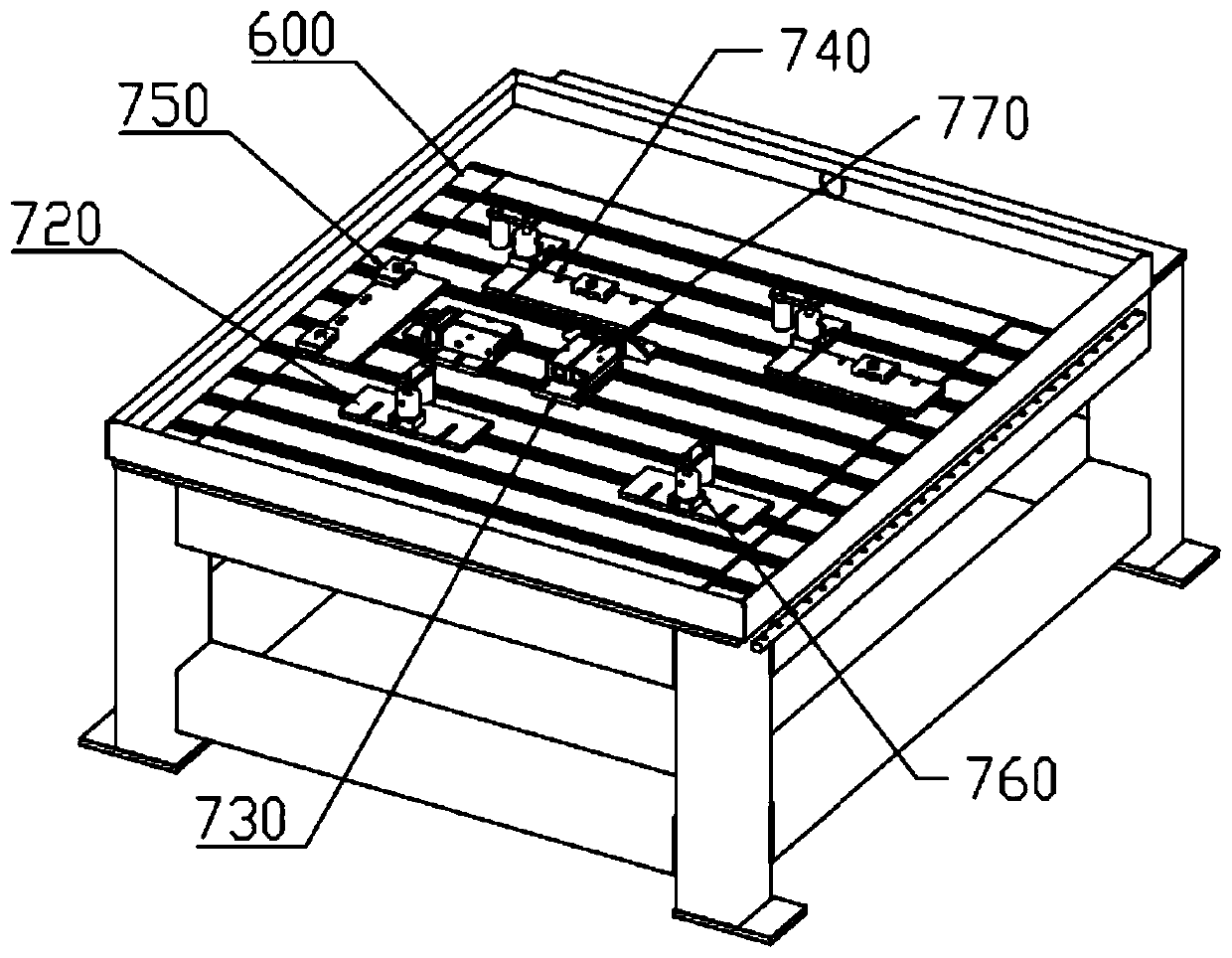

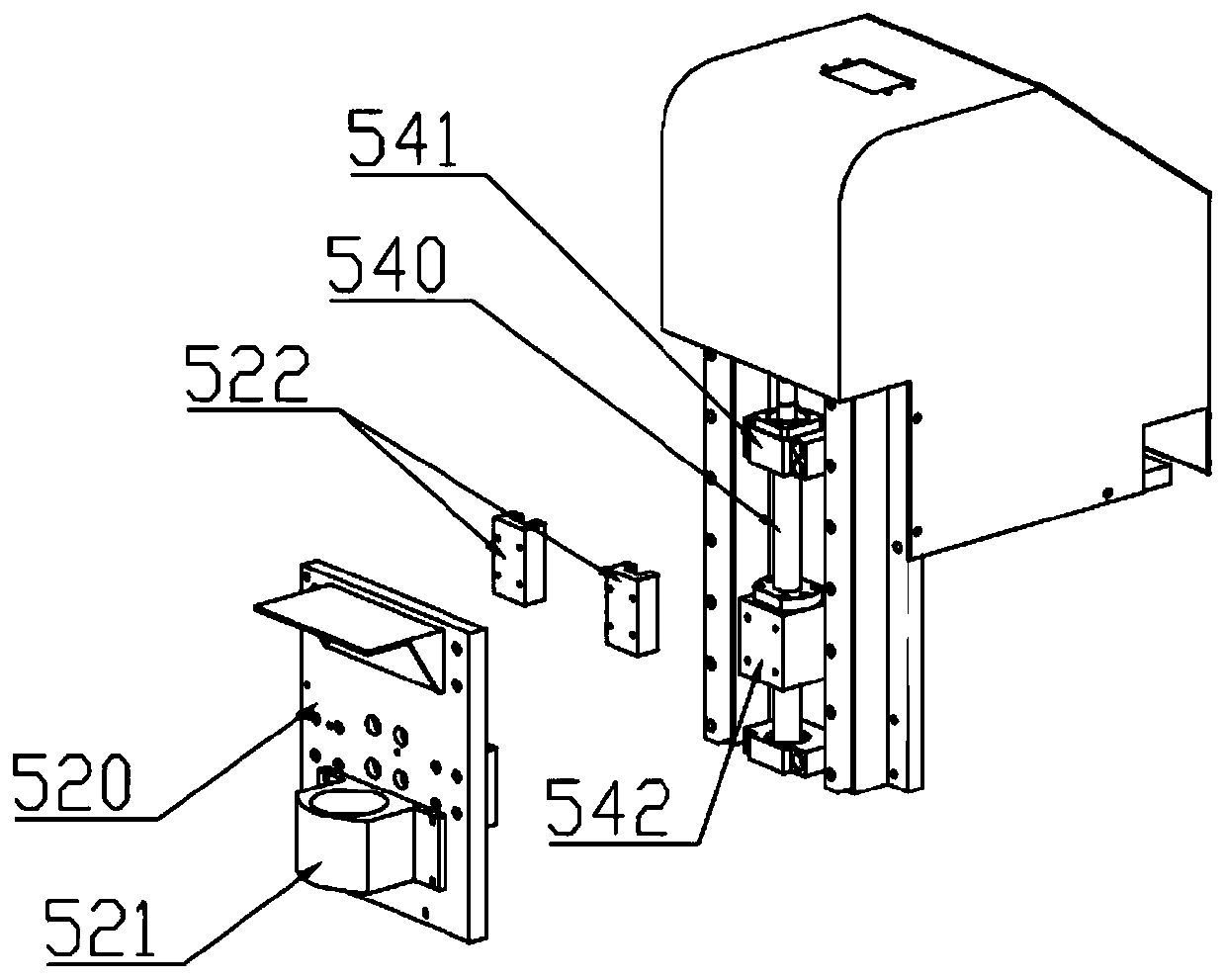

[0027] Please refer to figure 1 As shown, it is a preferred embodiment of the present invention, including a workbench 100, specifically, first horizontal slide rails 200 are provided on both sides of the workbench 100, and a crossbeam 40 support 300 is installed on the first horizontal slide rail 200 The beam bracket 300 is built with a first horizontal adjustment motor that drives the beam 400 bracket to move on the first horizontal slide rail 200. The upper end of the beam bracket 300 is connected with a beam 400 to form a gantry structure. Two horizontal slide rails 410. The second horizontal slide rail 410 is provided with a processing mechanism 500. The proc...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap