Planar complex structural space and large stroke type lamina emergent torsional joint

A technology of compliant hinge and composite structure, applied in the direction of program control manipulator, joint, shock absorber, etc., can solve the problem of small overall stroke and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with specific examples.

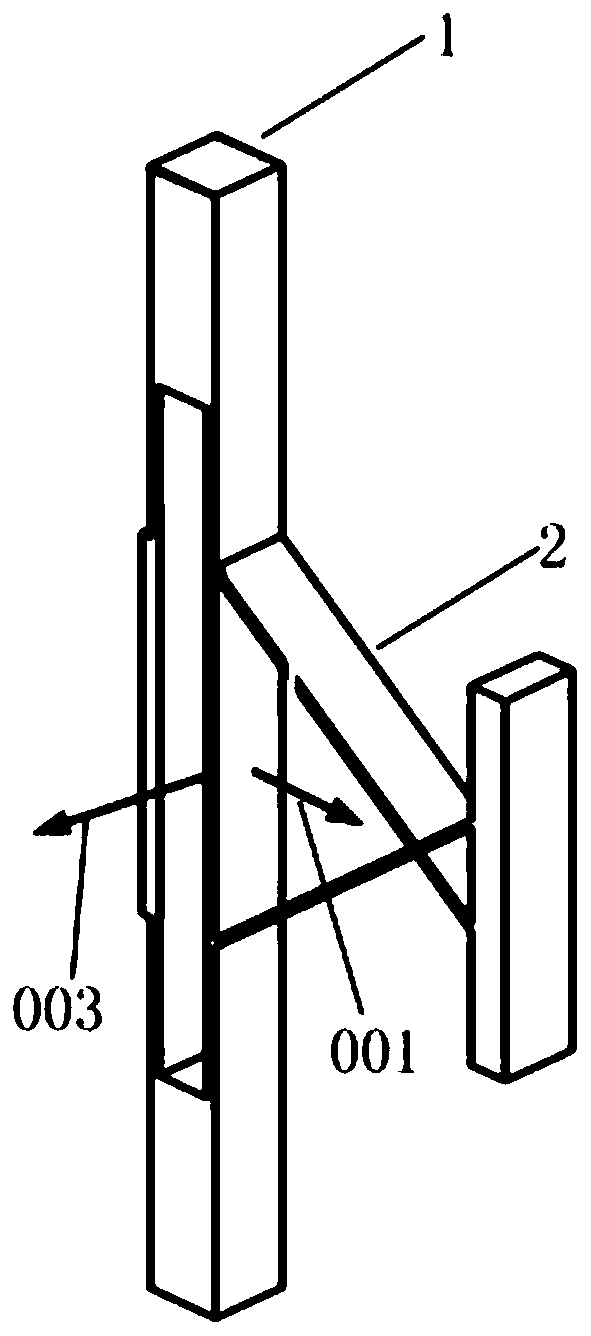

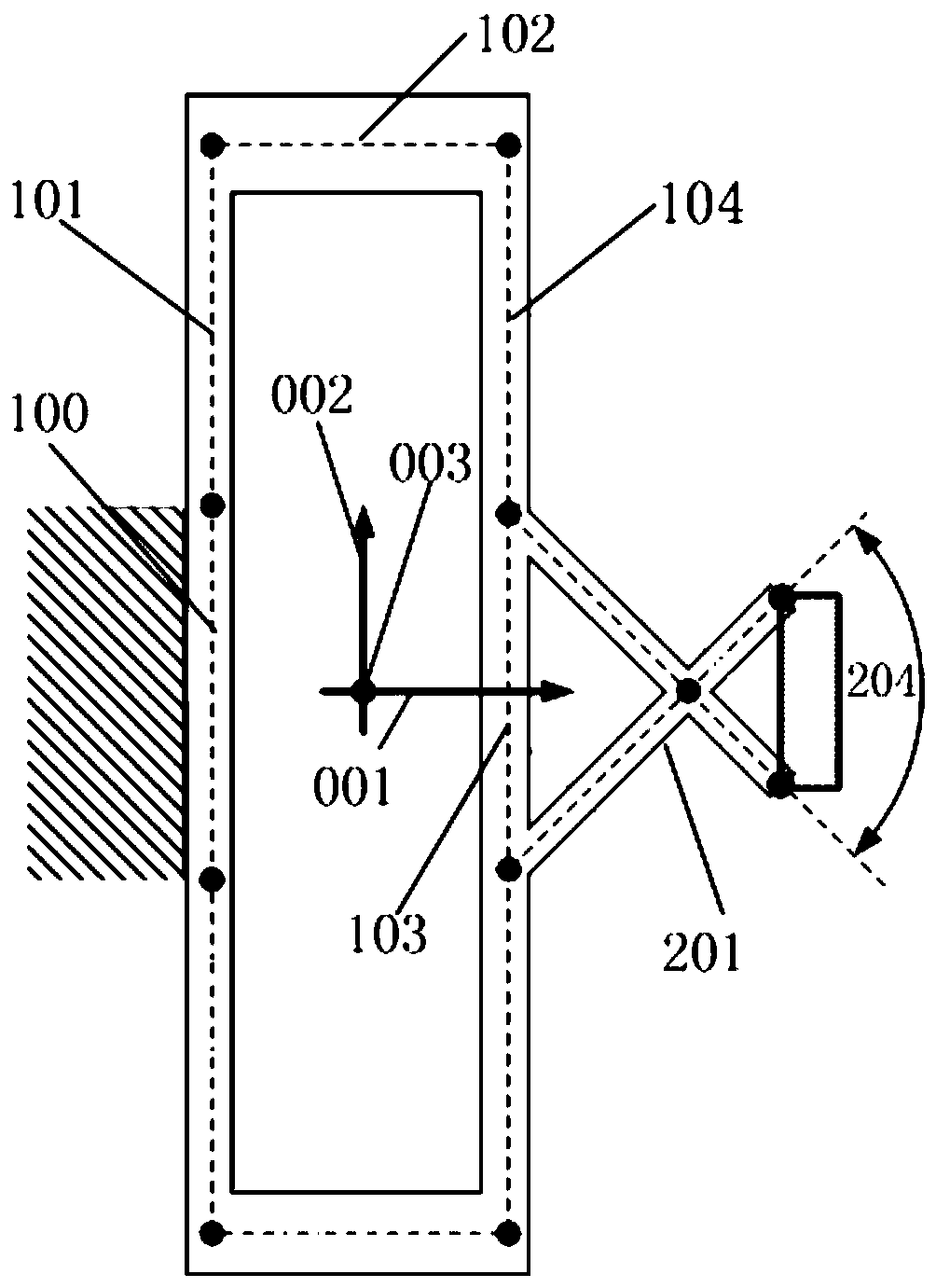

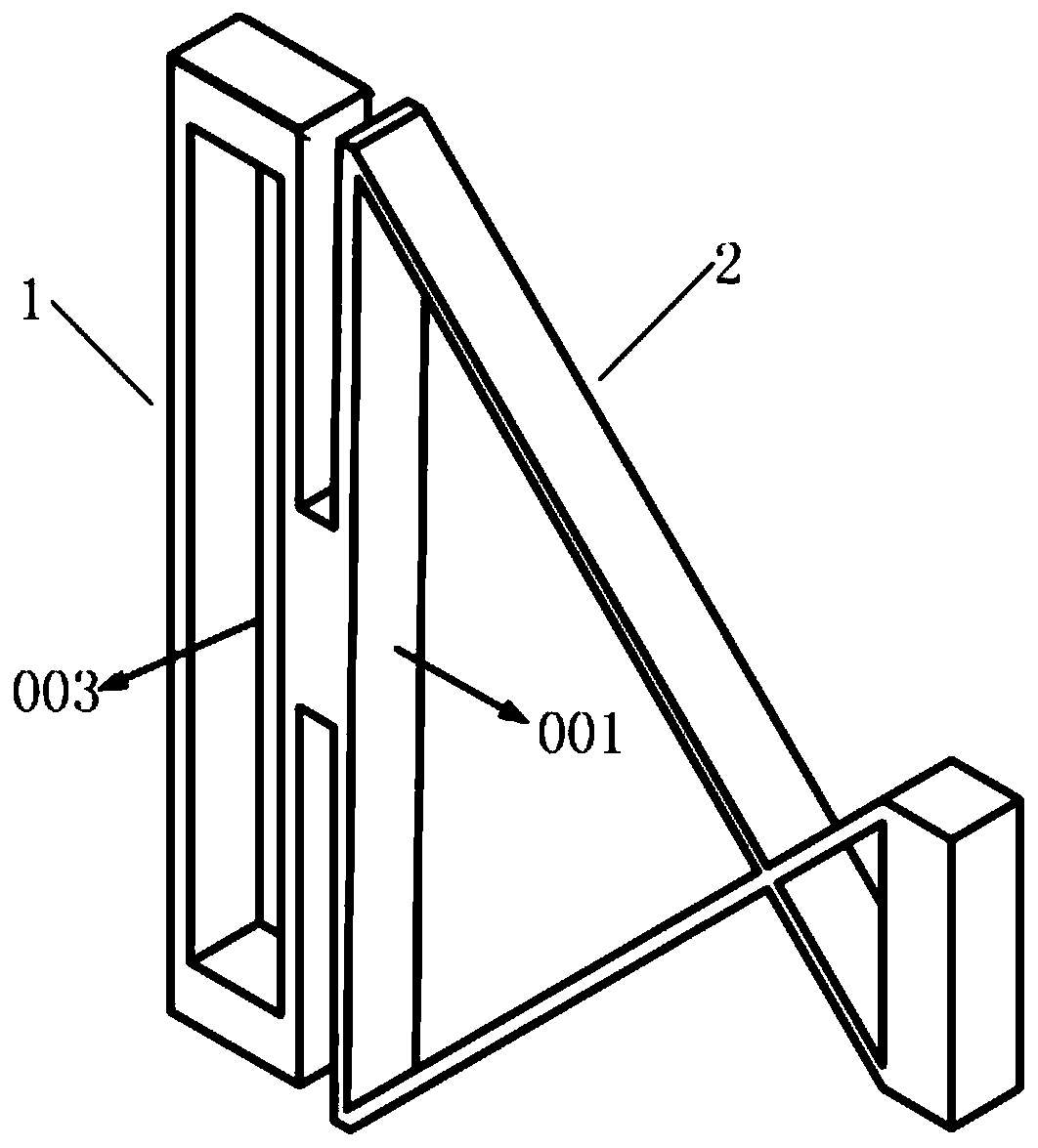

[0029] Such as figure 1 , figure 2As shown, the compliant hinge with a planar composite structure and a large stroke proposed in this embodiment includes a connected rectangular planar unit 1 and a fork-shaped planar unit 2. The rectangular planar unit 1 is used to realize the out-of-plane torsion function. The rectangular planar unit 1 is a rectangular structure surrounded by two flexible long straight beams and two flexible short straight beams 102, wherein the center of one long straight beam is a fixed section 100, and its two ends are respectively the first torsion section 101, the center of another long straight beam is a second torsion section 103, and its two ends are respectively a third torsion section 104; the fork-shaped plane unit 2 is used to realize the in-plane rotation function, and the fork-shaped plane unit 2 is A fork-shaped structure composed of two fle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com