FSAE racing fuel tank

A technology for fuel tanks and fuel tank caps, which is applied to the substructure and other directions, can solve problems such as unsmooth exhaust, achieve the effects of reducing weight, lowering the center of gravity, and improving lightweight performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

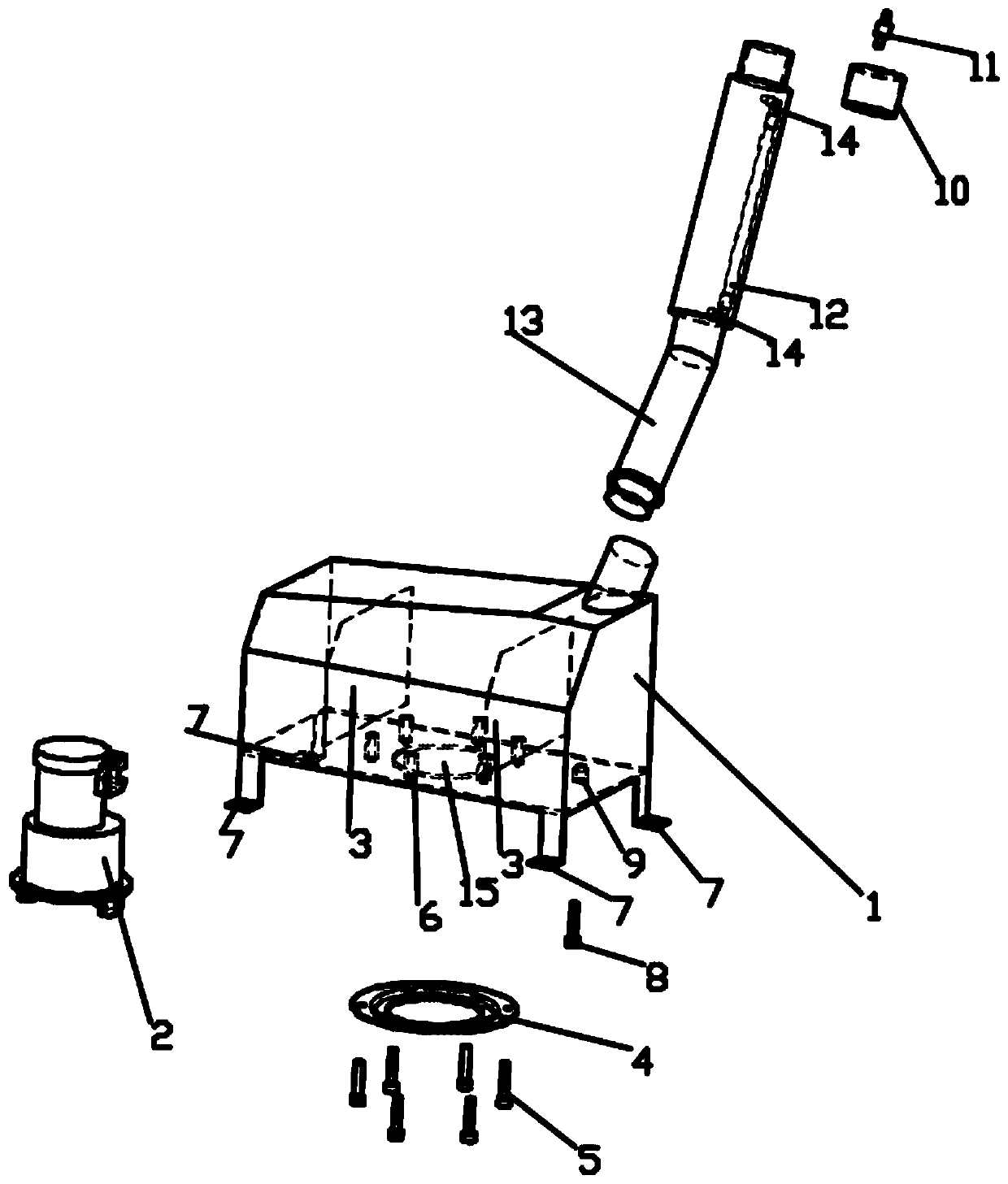

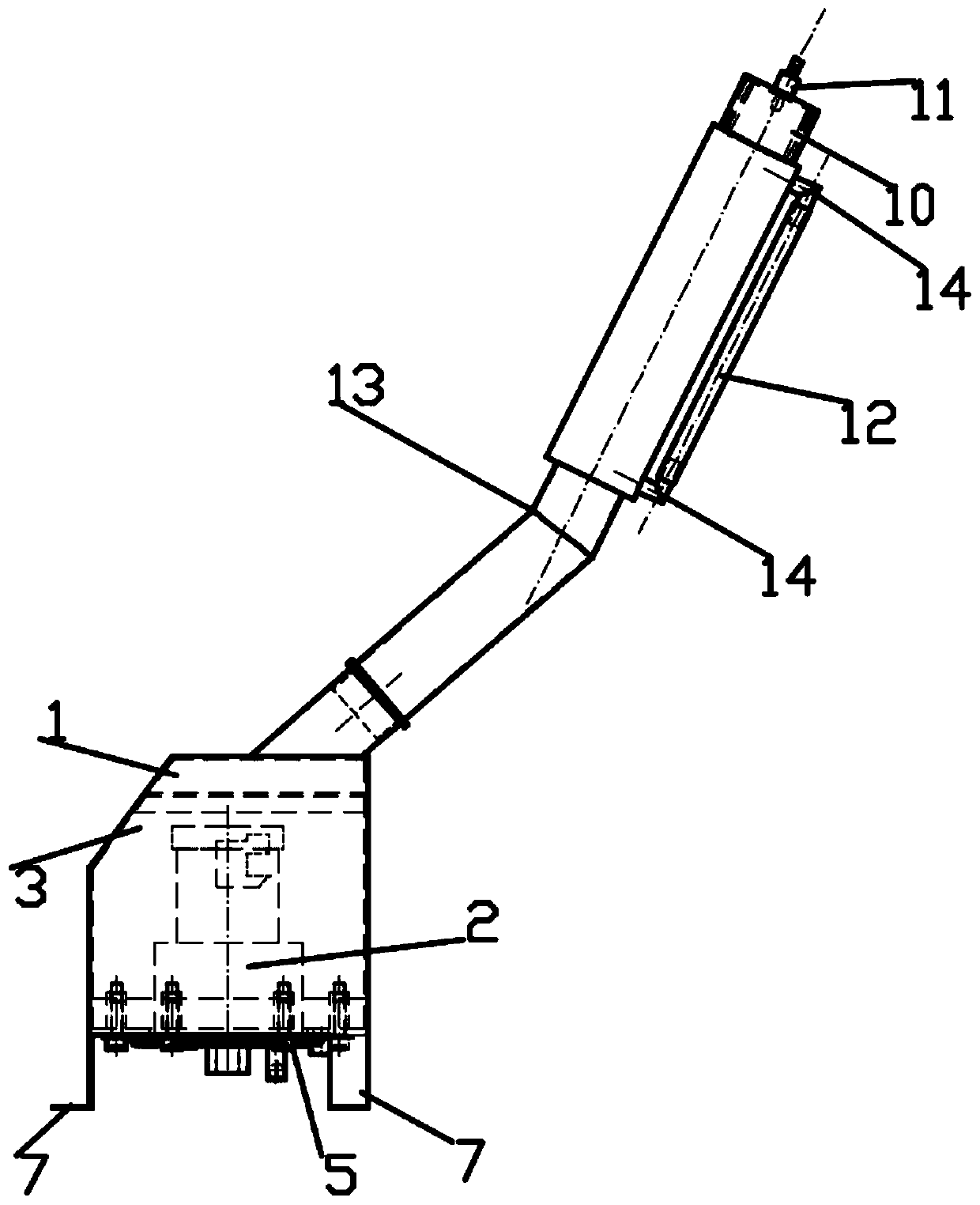

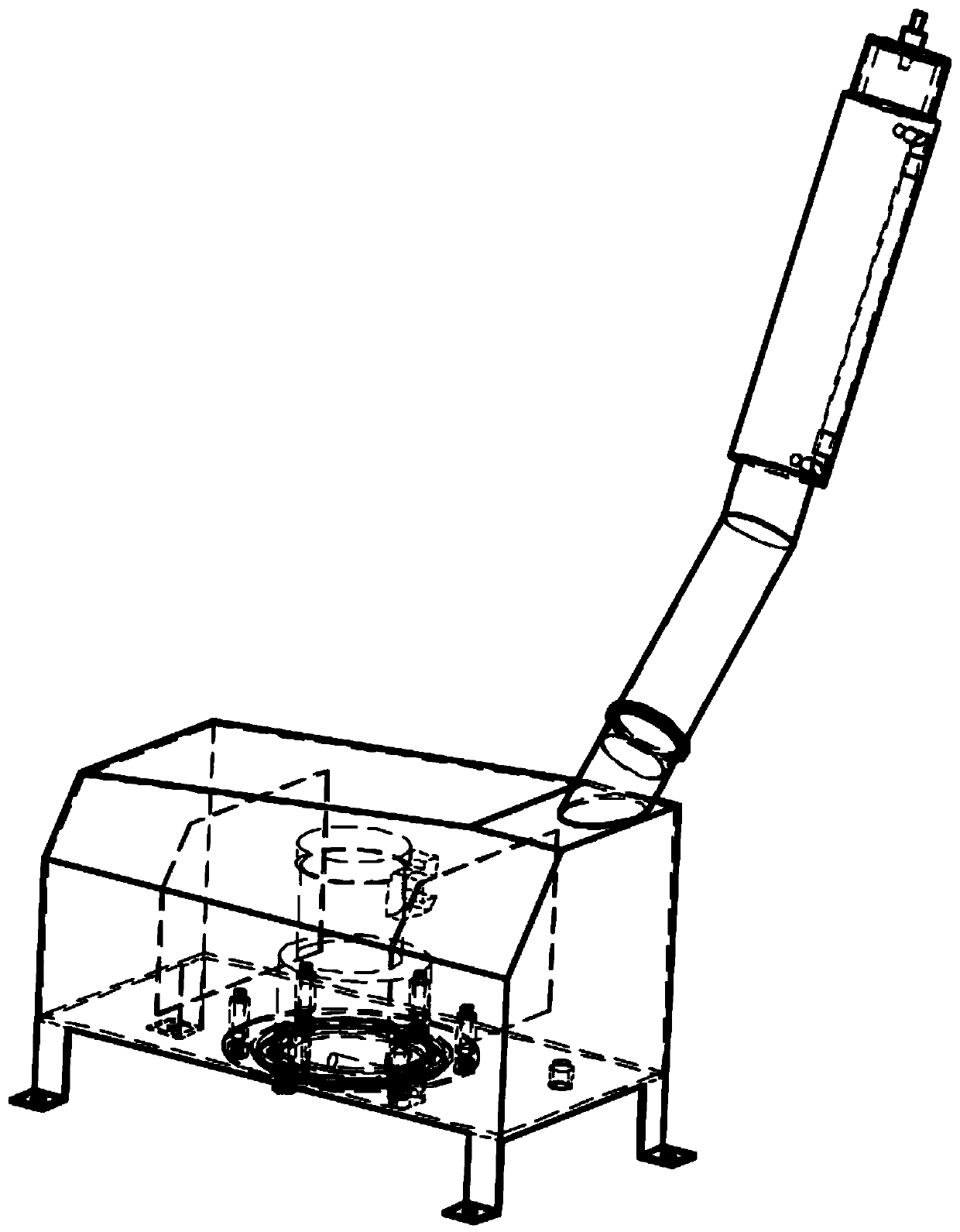

[0020] In order to illustrate the technical scheme and technical purpose of the present invention, the present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

[0021] to combine Figure 1-Figure 3 , a FSAE racing car fuel tank of the present invention and its assembly method, including a fuel tank body 1, an oil pump 2, a baffle plate 3, an oil pump pressure plate 4, a fuel tank lug 7, an oil drain bolt 8, an oil neck 13, and a right-angle elbow 14 , fuel tank cap 10, one-way valve 11;

[0022] The fuel tank body 1 is a trapezoidal cavity structure, made of 5052 aluminum plate, and the bottom is provided with an oil pump installation hole 15; the oil pump 2 is inserted into the oil pump installation hole 15 from the bottom of the fuel tank body 1, which can more effectively suck the oil at the bottom of the oil tank. fuel. The oil pump pressure plate 4 is installed at the bottom of the oil pump 2, and a plur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com