Aerial AGV sheet conveying method and system

A material and feeding technology, which is applied in the field of aerial AGV sheet material conveying methods and systems, can solve the problems of low production efficiency, low yield rate and high labor cost, and achieve high work efficiency, simple structure and good safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

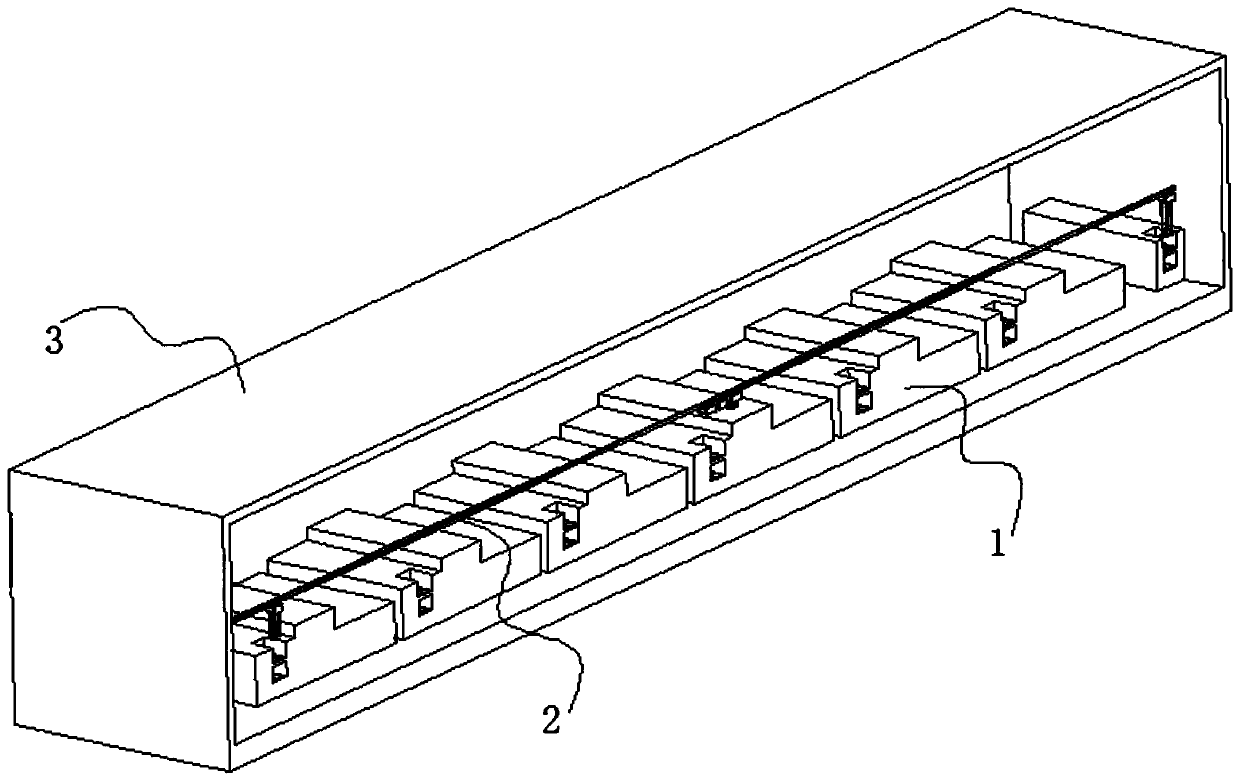

[0023] see Figures 1 to 4 , the aerial AGV sheet material conveying method provided in the present embodiment, comprises the following steps:

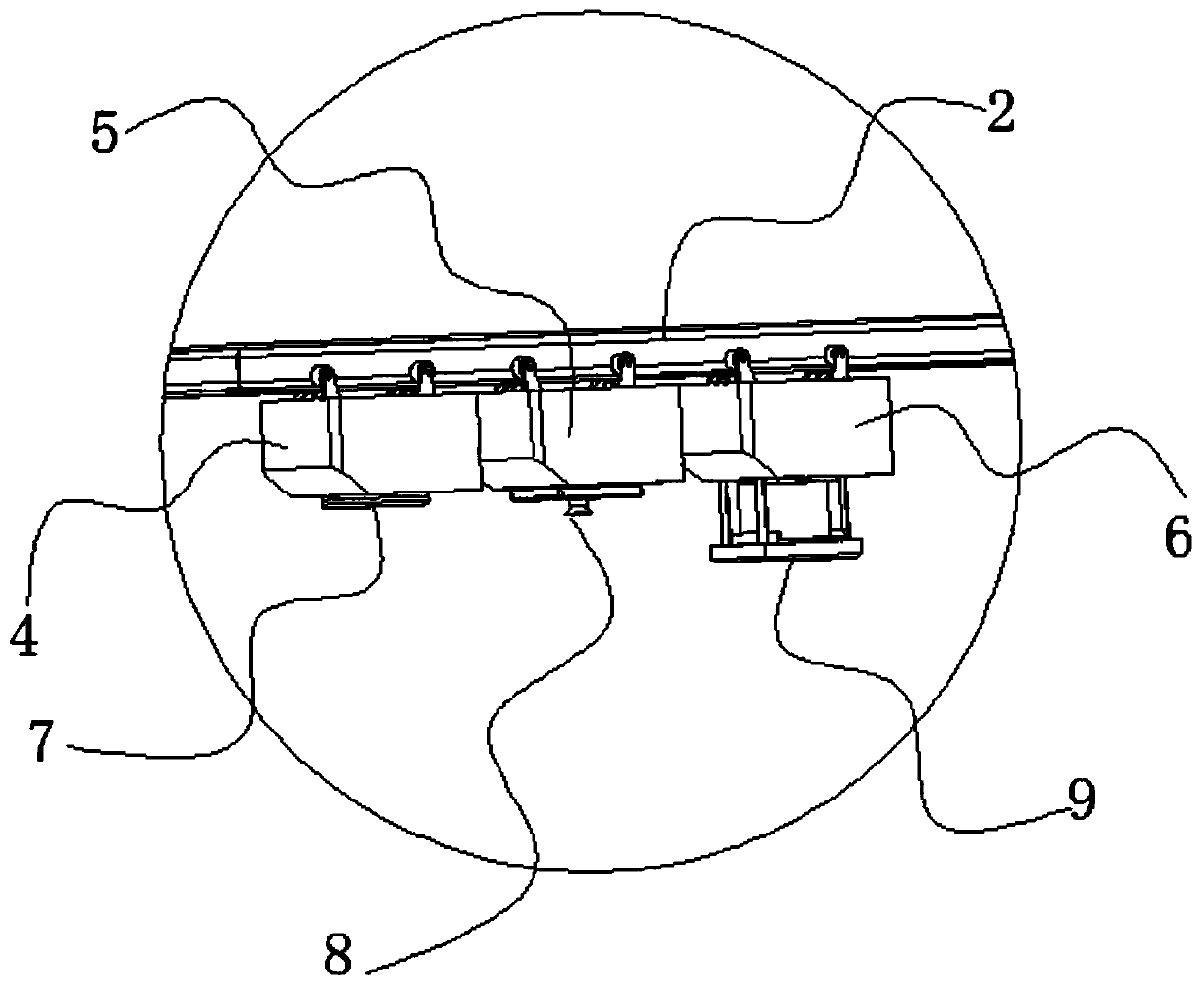

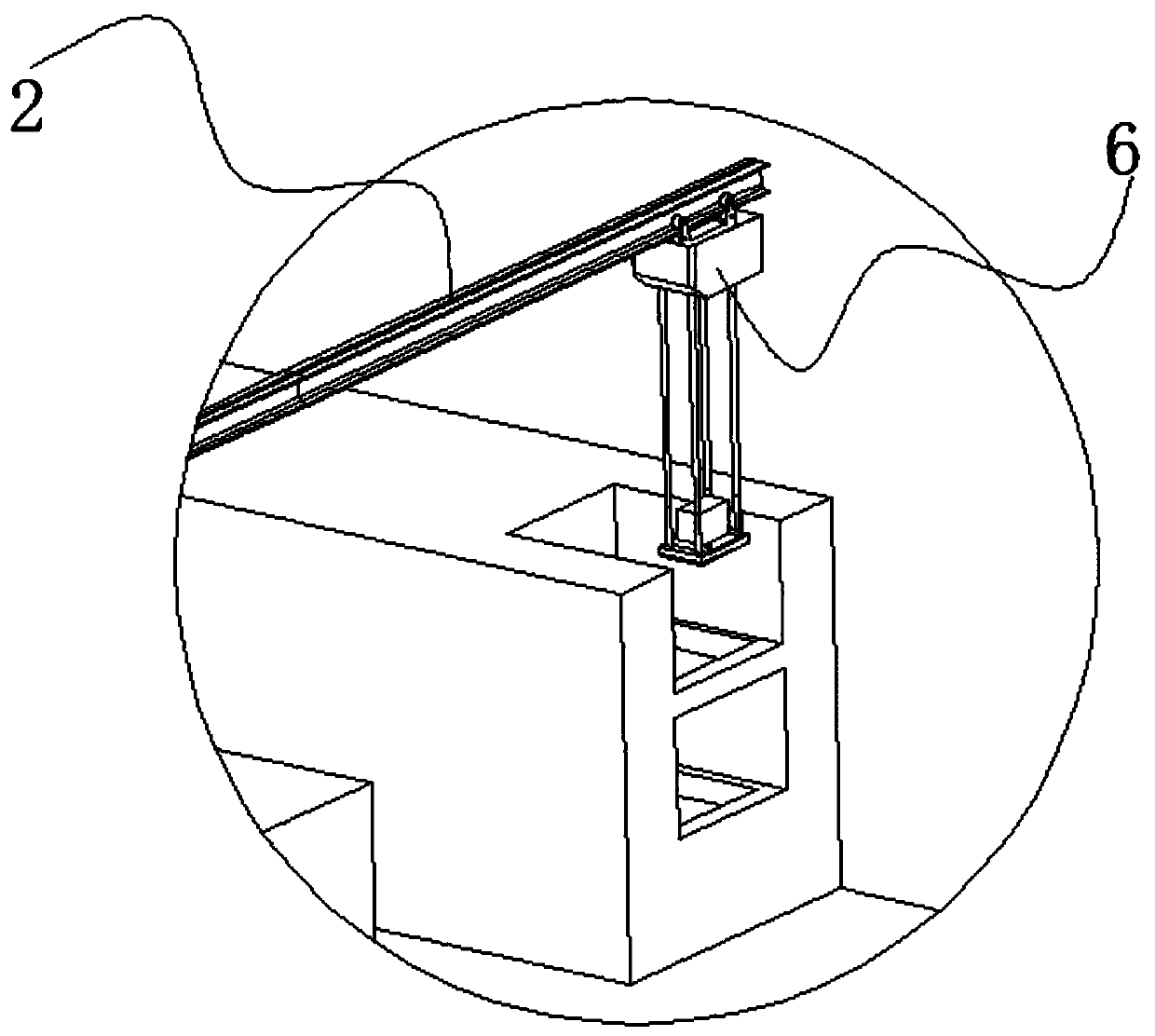

[0024] 1) Set the AGV track 2 above the CNC processing equipment 1. The two ends of the AGV track 2 are fixed on the factory building 3, which is set overhead, and the vertical height from the CNC processing equipment 1 is 2~4m; on the AGV track 2 in turn A patrol car 4, a fire truck 5 and an AGV feeding car 6 are set, the patrol car 4 is provided with a camera device, an infrared imaging device (combined into a detection device 7), and the fire truck 5 is provided with a fire spray device 8, The AGV feeding car 6 is provided with a lifting type pick-and-place device 9; the left end of the AGV track 2 is set as a loading station, the right end is set as a blanking station, and the middle section is set as a pick-and-place station;

[0025] 5) The inspection vehicle 4, the fire engine 5 and the AGV feeding vehicle 6 move to the loadin...

Embodiment 2

[0032] This embodiment is basically the same as Embodiment 1, except that the numerical control machining equipment 1 includes multiple rows or columns, and correspondingly, the AGV track 2 includes multiple rows or columns.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com