Lifting equipment system and control method thereof

A control method and equipment technology, applied in the direction of track systems, special data processing applications, instruments, etc., can solve the problems of large dust, short life of travel switches, prone to misoperation, etc., and achieve the effect of flexible parameter setting and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in further detail below in conjunction with the accompanying drawings.

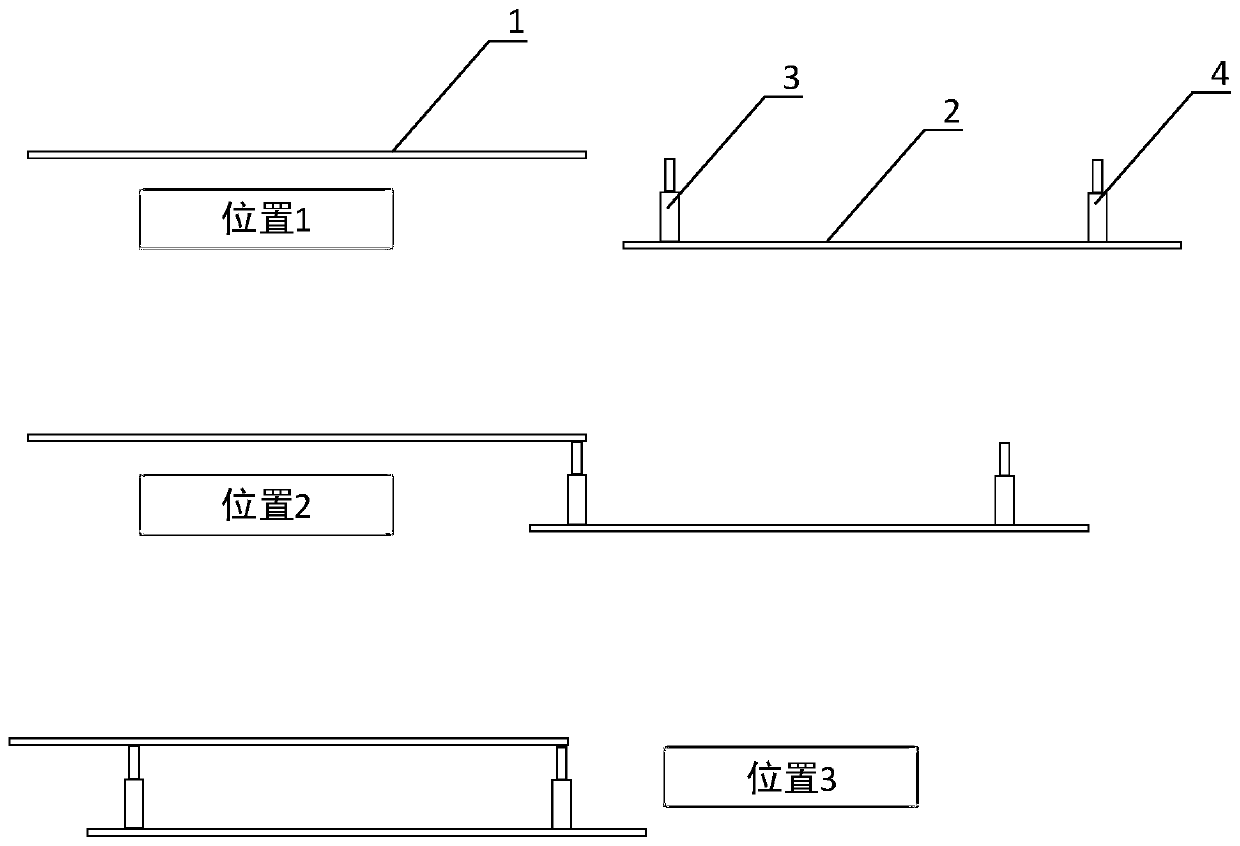

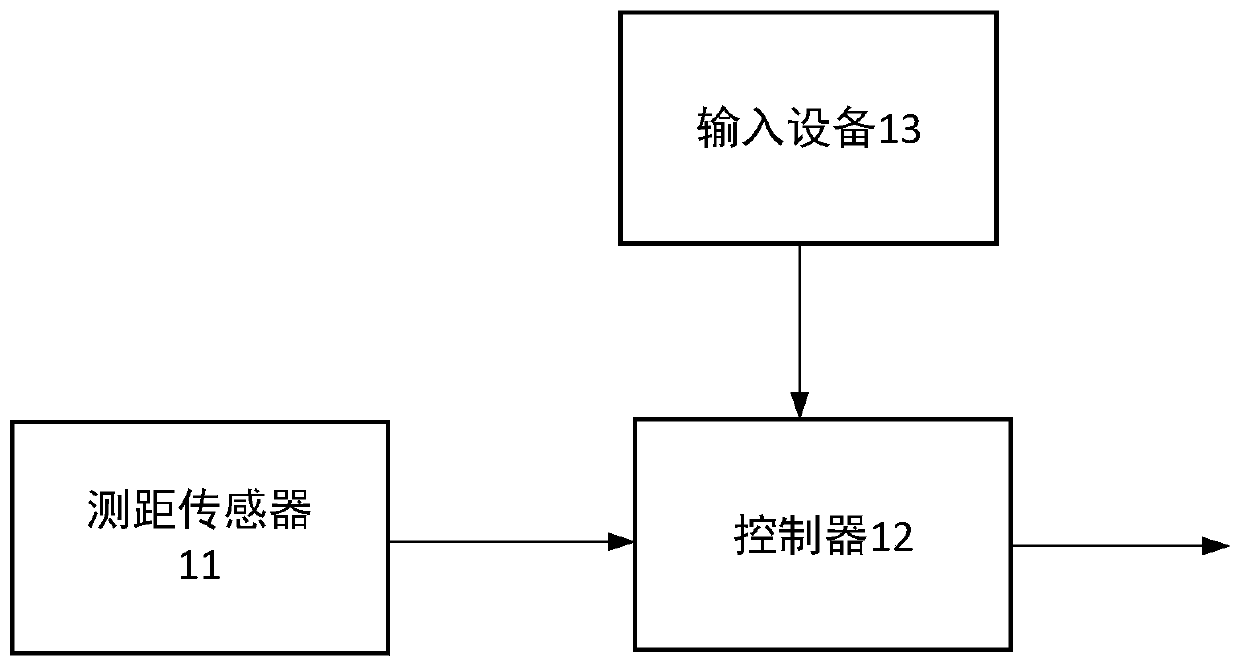

[0050] A lifting equipment system of the present application, such as figure 2 as shown,

[0051] It includes a distance measuring sensor 11, a controller 12, and an input device 13. The distance measuring sensor 11 is used to measure the movement of the lifting device. The controller 12 calculates and corrects the movement distance according to the measurement data, and outputs a control signal; the input device 13 Used to enter parameters or commands and display them. The controller is respectively connected with the input device and the distance measuring sensor.

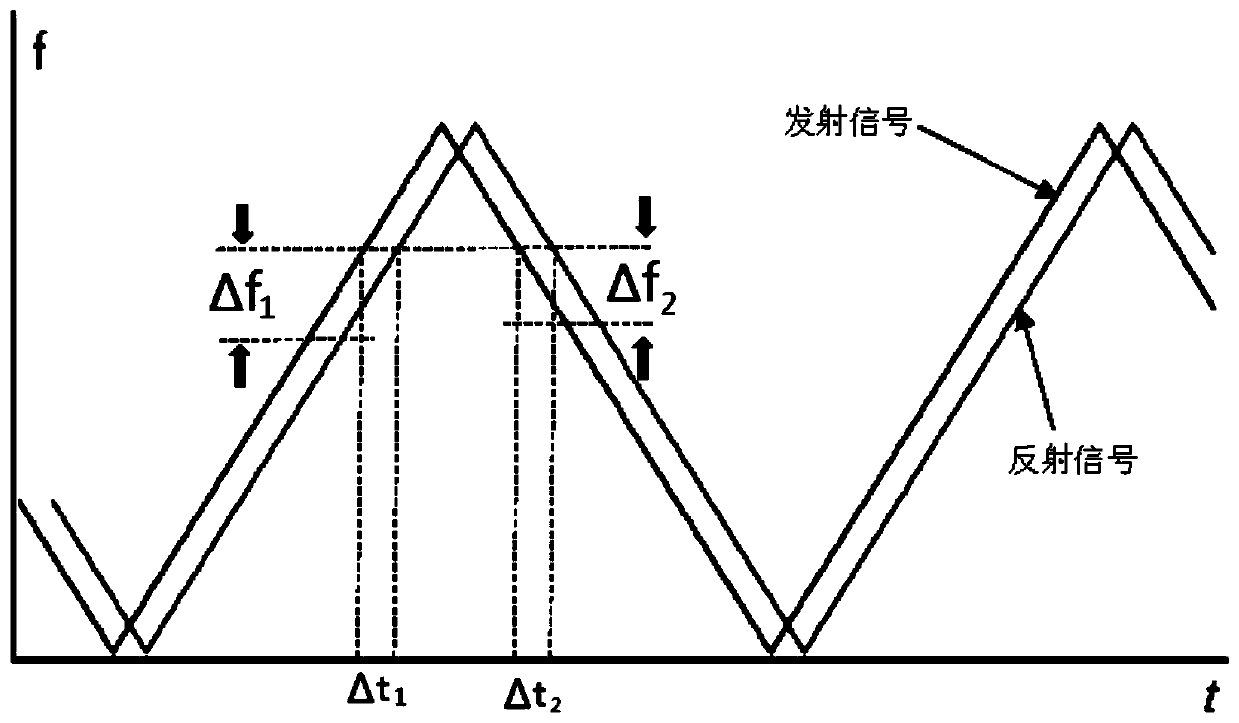

[0052] The controller 12 uses the ranging algorithm to calculate the moving distance of the lifting equipment according to the detection data of the ranging sensor 11, and corrects the moving distance according to the filtering algorithm, and then uses the anti-shake Algorithm, get the contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com