A kind of preparation method of one-dimensional perovskite micro-nanocrystal

A micro-nano and perovskite technology, applied in the preparation of organic compounds, nanotechnology, nano-optics, etc., can solve problems such as uncontrollable size and morphology, limiting material research and practical application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

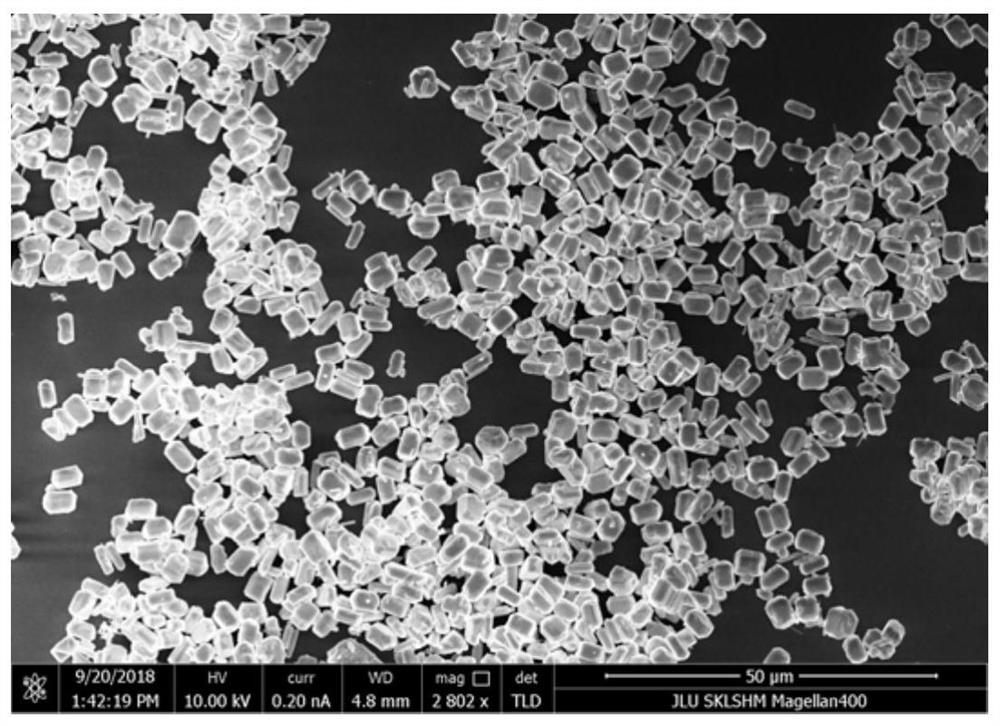

[0031] Example 1 The amount of oleylamine injected was 0.03mL, the amount of oleic acid was 2.5mL, and the preparation (C 4 N 2 h 14 )PbBr 4 micro-nano block

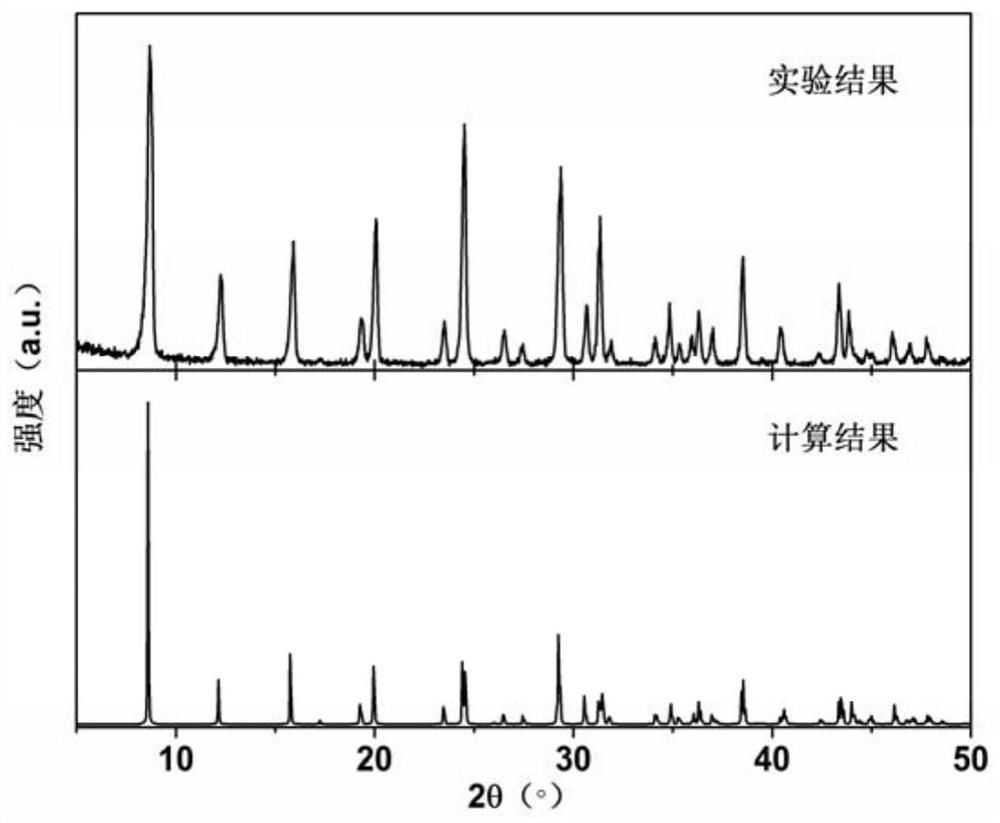

[0032] Put 0.2mmol of lead oxide, 5mL of octadecene, 2.5mL of oleic acid and 0.03mL of oleylamine into a three-neck flask and with strong magnetic stirring, gradually raise the temperature to 130°C under the protection of nitrogen and keep it for 1h During this process, the color of the solution changed from a yellow turbid solution to a light yellow clear solution, and then the temperature was naturally lowered to 60°C, and 0.5 mmol of N,N'dimethylethylenediamine was injected, and the solution turned into a tea-yellow clear solution, and then added 0.8mmol (0.1mL) of bromotrimethylsilane, the solution rapidly turns into a white suspension, indicating that (C 4 N 2 h 14 )PbBr 4 micro-nanocrystal formation. Take it out after 2min and inject toluene to quench the reaction. Such as figure 1 Shown as (C 4 N 2 h ...

Embodiment 2

[0033] In Example 2, the amount of oleylamine injected was increased to 0.06mL, the amount of oleic acid was 2.5mL, prepared under the reaction at 80°C (C 4 N 2 h 14 )PbBr 4 micro-nano block

[0034] Put 0.2mmol of lead oxide, 5mL of octadecene, 2.5mL of oleic acid and 0.06mL of oleylamine into a three-neck flask and with strong magnetic stirring, gradually raise the temperature to 130°C under the protection of nitrogen and keep it for 1h During this process, the color of the solution changed from a yellow turbid solution to a light yellow clear solution, and then the temperature was naturally lowered to 80°C, and 0.5mmol of N,N'dimethylethylenediamine was injected, and the solution turned into a tea-yellow clear solution, and then added 0.8mmol (0.1mL) of bromotrimethylsilane, the solution rapidly turns into a white suspension, indicating that (C 4 N 2 h 14 )PbBr 4 micro-nanocrystal formation. Take it out after 2min and inject toluene to quench the reaction. Such as ...

Embodiment 3

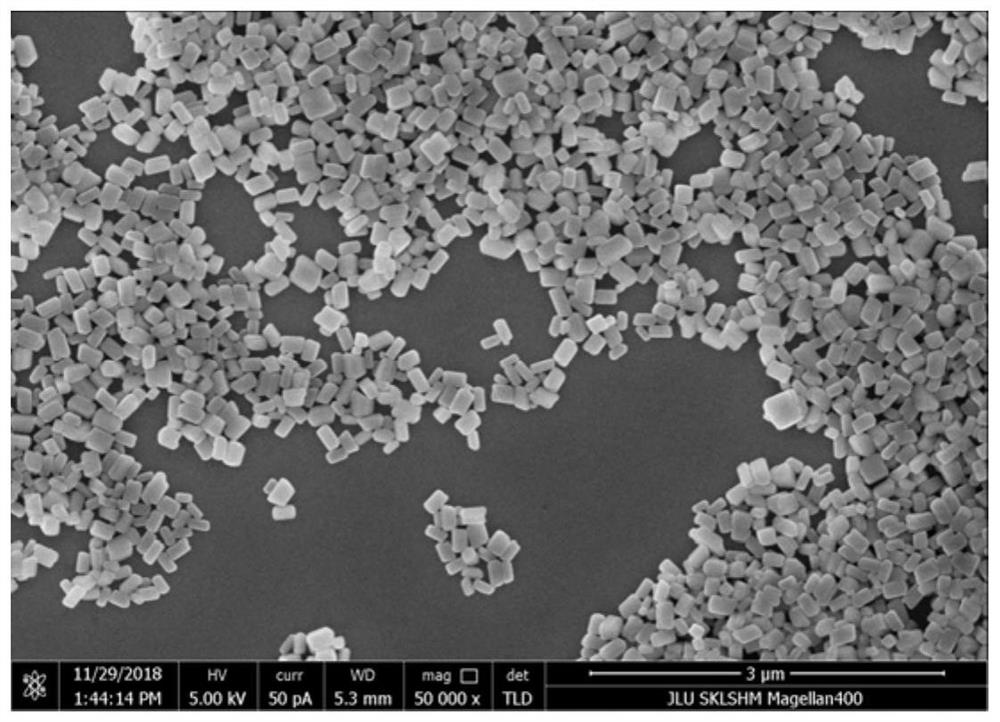

[0035] Example 3 The amount of oleylamine injected was increased to 0.06mL, the amount of oleic acid was 2.5mL, and the reaction was prepared at 60°C (C 4 N 2 h 14 )PbBr 4 micro-nanorod

[0036] Put 0.2mmol of lead oxide, 5mL of octadecene, 2.5mL of oleic acid and 0.06mL of oleylamine into a three-neck flask and with strong magnetic stirring, gradually raise the temperature to 130°C under the protection of nitrogen and keep it for 1h During this process, the color of the solution changed from a yellow turbid solution to a light yellow clear solution, and then the temperature was naturally lowered to 60°C, and 0.5 mmol of N,N'dimethylethylenediamine was injected, and the solution turned into a tea-yellow clear solution, and then added 0.8mmol (0.1mL) of bromotrimethylsilane, the solution rapidly turns into a white suspension, indicating that (C 4 N 2 h 14 )PbBr 4 micro-nanocrystal formation. Take it out after 2min and inject toluene to quench the reaction. Such as Fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap