A kind of polydiselenium carbonate polymer, preparation method and application thereof

A technology of carbonate polymers and carbonates, which is applied in the direction of drug combinations, pharmaceutical formulations, medical preparations of non-active ingredients, etc., can solve the problems of uncontrollable structure of selenium-containing polymers, difficult biodegradation, and limited applications, etc., to achieve Reduce the body's drug resistance, controllable structure, single ingredient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

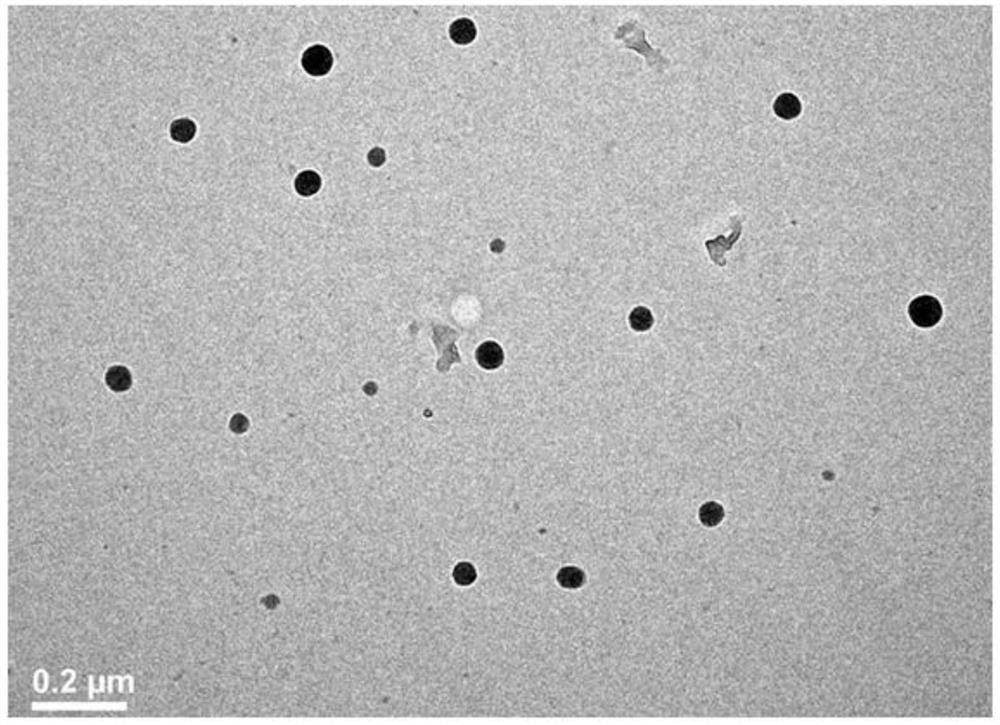

Image

Examples

Embodiment 1

[0040] Synthesis of polydiselenium carbonate polymer PSeSeTMC839:

[0041]

[0042] Under argon protection, polyethylene glycol monomethyl ether MPEG (M n =2000, 100mg, 0.05mmol), macrocyclic bis-selenocarbonate monomer M SeSe (280mg, 0.5mmol) and trimethylene carbonate monomer TMC (202mg, 2.0mmol) were quickly added to the polymerization bottle that had been pumped and roasted three times in advance, and after vacuuming for 3 hours, 48mg of Novozym435 enzyme and 3.8mL of dry toluene were added. Reaction at 70°C for 72h. After the reaction, add 4 to 8 mL of dichloromethane to dissolve, filter to remove the enzyme, and settle with about 100 mL of ice anhydrous ether to obtain a yellow polymer that is vacuum-dried to constant weight to obtain a polydiselenium carbonate polymer PSeSeTMC839 with a P of 45 , m is 8, n is 39. 1 H NMR (400MHz, CDCl 3 ):δ4.42(-OCOOCH 2 ), 4.24 (-OCOO CH 2 CH 2 Se), 3.16 (CH 2 CH 2 Se), 2.05 (-OCOOCH 2 CH 2 ), 3.65 and 3.38 are MPEG repea...

Embodiment 2

[0047] Synthesis of polydiselenium carbonate polymer PSeSeTMC646:

[0048]

[0049] Under argon protection, polyethylene glycol monomethyl ether MPEG (M n =2000, 100mg, 0.05mmol), macrocyclic bis-selenocarbonate monomer M SeSe (224mg, 0.4mmol) and trimethylene carbonate monomer TMC (255mg, 2.5mmol) were quickly added to the polymerization bottle that had been pumped and baked three times in advance, and after vacuuming for 3 hours, 48mg of Novozym435 enzyme and 3.8mL of dry toluene were added. Reaction at 70°C for 72h. After the reaction, add 4-8 mL of dichloromethane to dissolve, remove the enzyme by filtration, and settle with about 100 mL of ice anhydrous ether to obtain a yellow polymer that is vacuum-dried to constant weight to obtain a polydiselenium carbonate polymer PSeSeTMC646 with a P of 45 , m is 6, n is 46. 1 H NMR (400MHz, CDCl 3 ):δ4.42(-OCOOCH 2 ), 4.24 (-OCOO CH 2 CH 2 Se), 3.16 (CH 2 CH 2 Se), 2.05 (-OCOOCH 2 CH 2 ), 3.65 and 3.38 are MPEG repeat...

Embodiment 3

[0051] Synthesis of polydiselenium carbonate polymer PSeSeTMC459:

[0052]

[0053] Under argon protection, polyethylene glycol monomethyl ether MPEG (M n =2000, 100mg, 0.05mmol), macrocyclic bis-selenocarbonate monomer M SeSe (140mg, 0.25mmol) and trimethylene carbonate monomer TMC (306mg, 3mmol) were quickly added to the polymerization bottle that had been pumped and roasted three times in advance, and after vacuuming for 3h, 45mg of Novozym435 enzyme and 3.6mL of dry toluene were added, at 70 Reaction at ℃ for 72h. After the reaction, add 4-8 mL of dichloromethane to dissolve, filter to remove the enzyme, and settle with about 100 mL of ice anhydrous ether to obtain a yellow polymer that is vacuum-dried to constant weight to obtain a polydiselenium carbonate polymer PSeSeTMC459 with a P of 45 , m is 4, n is 59. 1 H NMR (400MHz, CDCl 3 ):δ4.41(-OCOOCH 2 ), 4.24 (-OCOO CH 2 CH 2 Se), 3.16 (CH 2 CH 2 Se), 2.05 (-OCOOCH 2 CH 2 ), 3.65 and 3.37 are MPEG repeat unit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com