A special adhesive for waterproof coiled material in ultra-low temperature environment and preparation method thereof

A waterproof membrane, ultra-low temperature technology, applied in the direction of adhesives, adhesive types, mineral oil hydrocarbon copolymer adhesives, etc., can solve the problem of low use temperature, and achieve excellent coating performance, excellent initial tack and stickiness. , the effect of good overlap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

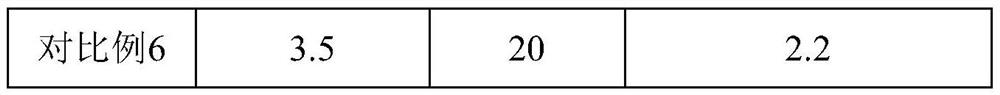

Examples

preparation example Construction

[0054] The second aspect of the present invention provides a method for preparing a special glue for waterproof coiled materials in an ultra-low temperature environment, the steps include:

[0055] (1) drop described naphthenic oil, antioxidant into stainless steel reactor;

[0056] (2) After the temperature rises to 140°C, add SBR rubber, and control the temperature of the reactor at 150°C;

[0057] (3) After the SBR rubber is completely dissolved, put in hydrogenated C5 petroleum resin, aromatic modified terpene resin, ethylene-acrylic acid salt, and carboxyl-terminated hyperbranched polyester, and control the temperature of the stainless steel reactor within 200°C and stir for 30-60 minutes , evacuate to -0.085MPa, discharge and pack for cooling.

Embodiment 1

[0061] Example 1 provides a special adhesive for waterproof coiled materials in an ultra-low temperature environment, including the following components: 20 parts of hydrogenated C5 petroleum resin, 5 parts of aromatic modified terpene resin, 1 part of ethylene-acrylate, 22 parts of SBR rubber, 1 part of carboxyl-terminated hyperbranched polyester, 8 parts of naphthenic oil, and 0.5 part of antioxidant.

[0062] The hydrogenated C5 petroleum resin is a product commercially available from Kolon, Korea, with the brand name SU-100S.

[0063] The aromatic modified terpene resin is commercially available from Yasuhara Chemical Co., Ltd. under the brand name YS Resin TR105.

[0064] The ethylene-acrylic acid zinc salt is commercially available from DuPont, U.S., and the trade name is 1702 product.

[0065] The SBR rubber is a product commercially available from Yueyang Baling Huaxing Petrochemical Co., Ltd. with the brand name SBS-1401.

[0066] The carboxyl-terminated hyperbran...

Embodiment 2

[0074] Example 2 provides a special adhesive for waterproof coiled materials in an ultra-low temperature environment, including the following components: 25 parts of hydrogenated C5 petroleum resin, 10 parts of aromatic modified terpene resin, 3 parts of ethylene-acrylate, 30 parts of SBR rubber, 3 parts of carboxyl-terminated hyperbranched polyester, 12 parts of naphthenic oil, and 1 part of antioxidant.

[0075] The hydrogenated C5 petroleum resin is a product commercially available from Kolon, Korea, with the brand name SU-100S.

[0076] The aromatic modified terpene resin is commercially available from Yasuhara Chemical Co., Ltd. under the brand name YS Resin TR105.

[0077] The ethylene-acrylic acid zinc salt is commercially available from DuPont, U.S., and the trade name is 1702 product.

[0078] The SBR rubber is a product commercially available from Yueyang Baling Huaxing Petrochemical Co., Ltd. with the brand name SBS-1401.

[0079] The naphthenic oil is a product...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com