Method for preparing pH response type intelligent propping agent

A proppant and responsive technology, which is applied in the field of preparation of pH-responsive smart proppants, can solve the problems of poor modification and refinement effects, and achieve good application potential, good fluidity, and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

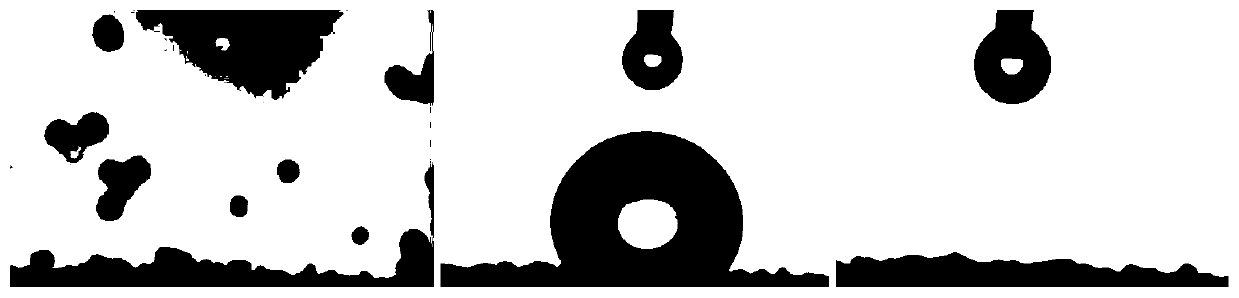

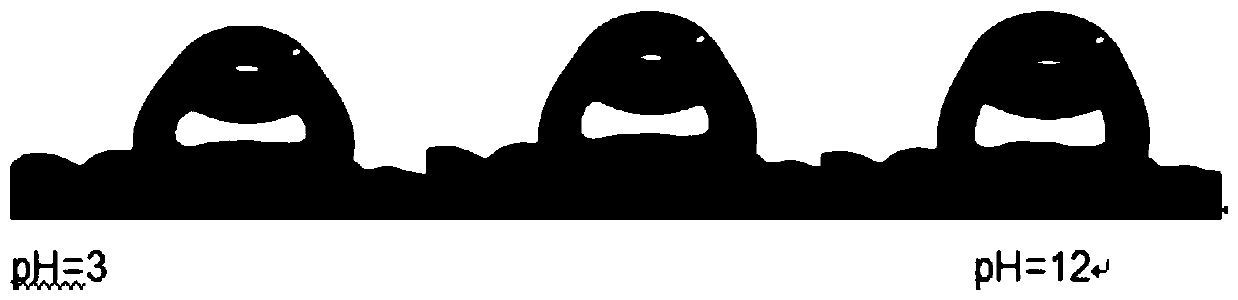

Image

Examples

Embodiment 1

[0056] A method for preparing a responsive intelligent proppant, using a molecular graft polymerization method, comprising the following steps:

[0057] (1) Sand particle surface initiator modification: Weigh 5g of 20-140 mesh sand proppant and disperse it in 100mL acetone to make a mixed solution, add it into a reagent bottle equipped with magnets, and slowly drop it in with a reagent needle under the condition of stirring 2g of chlorodimethylsilylbromopropyl bromide isobutyrate was stirred and heated in an oil bath at 90°C for 3h under the protection of nitrogen, condensed and refluxed for 10-20h, and cooled to room temperature. Washing and precipitating with tetrahydrofuran and acetone respectively; vacuum drying at room temperature to obtain a sand grain proppant with propyl chlorodimethylsilyl bromide isobutyrate on the surface.

[0058] (2) Grafting hydrophobic molecules: Weigh 100 mg of surface-modified sand into a 250 mL round-bottomed flask with a medicine spoon, put ...

Embodiment 2

[0061] A method for preparing a responsive intelligent proppant, using a molecular graft polymerization method, comprising the following steps:

[0062] (1) Ceramsite Surface Initiator Modification: Weigh 100g of 20-140 mesh ceramsite proppant and disperse it in 100mL of toluene to make a mixed solution, add it to the reagent bottle equipped with a magnet, and use a reagent needle to slowly 2g of dibromoisobutyryloxyethane was added dropwise, under the protection of nitrogen, stirred and heated in an oil bath at 50°C for 3h, condensed and refluxed for 20h, and cooled to room temperature. Washing and precipitating with tetrahydrofuran and acetone respectively; vacuum drying at room temperature to obtain the ceramsite proppant modified with dibromoisobutyryloxyethane on the surface.

[0063] (2) Molecular grafting method to connect hydrophobic brushes: Weigh 1000mg of surface-modified ceramsite into a 250mL round bottom flask with a medicine spoon, put it into a magnet, weigh 50...

Embodiment 3

[0066] A method for preparing a responsive intelligent proppant, using a molecular graft polymerization method, comprising the following steps:

[0067] (1) Sand particle surface initiator modification: Weigh 50g of 20-140 mesh sand proppant and disperse it in 150mL of acetone to make a mixed solution, add it into a reagent bottle equipped with magnets, slowly drop it in with a reagent needle under stirring conditions 2g of bromoisobutyryl bromide was stirred and heated in an oil bath at 150°C for 3h under the protection of nitrogen, condensed and refluxed for 15h, and cooled to room temperature. Washing and precipitating with tetrahydrofuran and acetone respectively; vacuum drying at room temperature to obtain a sand proppant modified with bromoisobutyryl bromide on the surface.

[0068] (2) Molecular grafting method to connect hydrophobic brushes: Weigh 500mg of surface-modified sand into a 250mL round-bottomed flask with a medicine spoon, put in a magnet, weigh 40mg of cupr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com