Starting end tunnel portal sealing device and method when shield tunneling machine starts to downwards transverse existing shield tunnel immediately

A shield tunneling and sealing device technology, applied in tunnels, earth-moving drilling, mining equipment, etc., can solve problems such as affecting the operation of existing lines, easy collapse of the face, and collapse of the face, so as to reduce soil damage. The effect of falling, convenient construction and smooth passage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

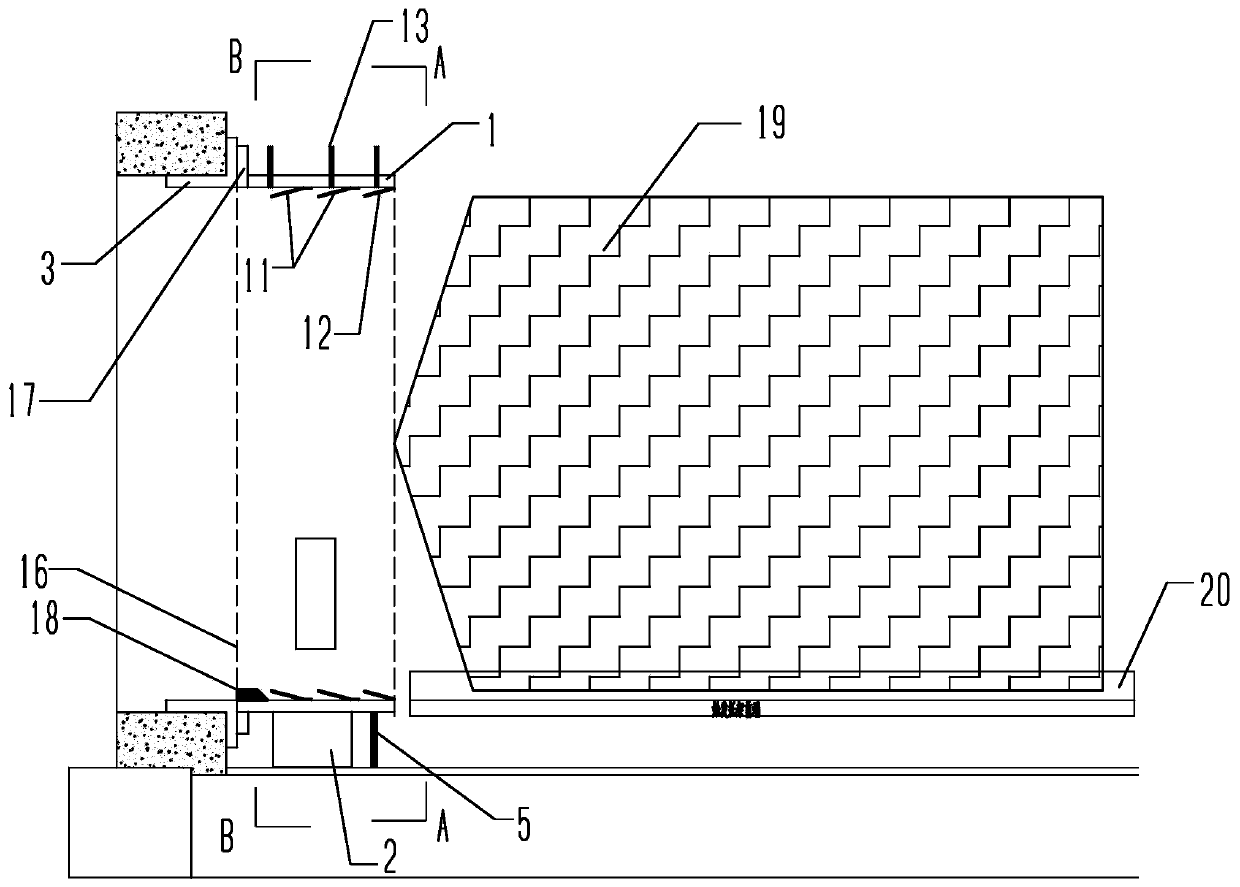

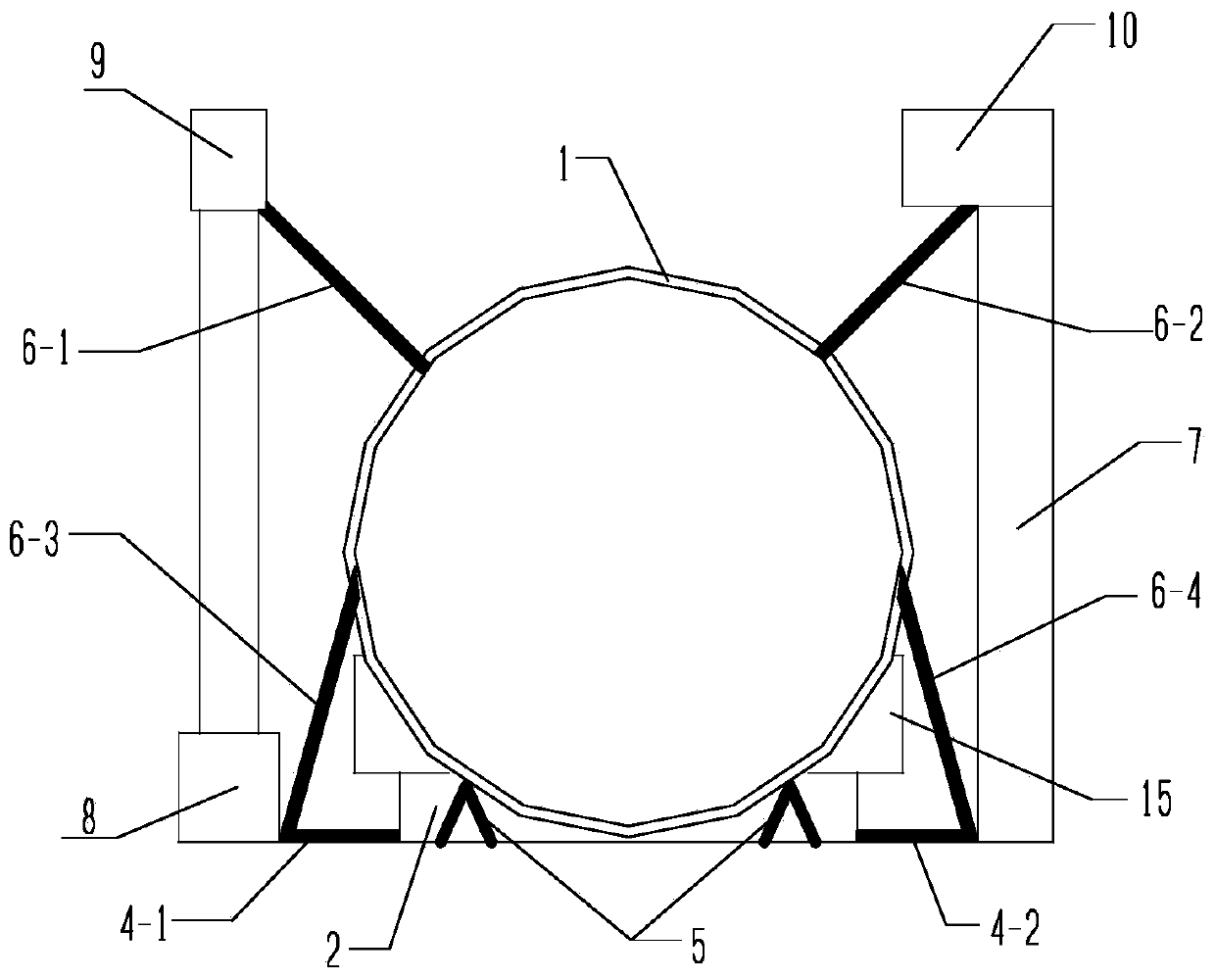

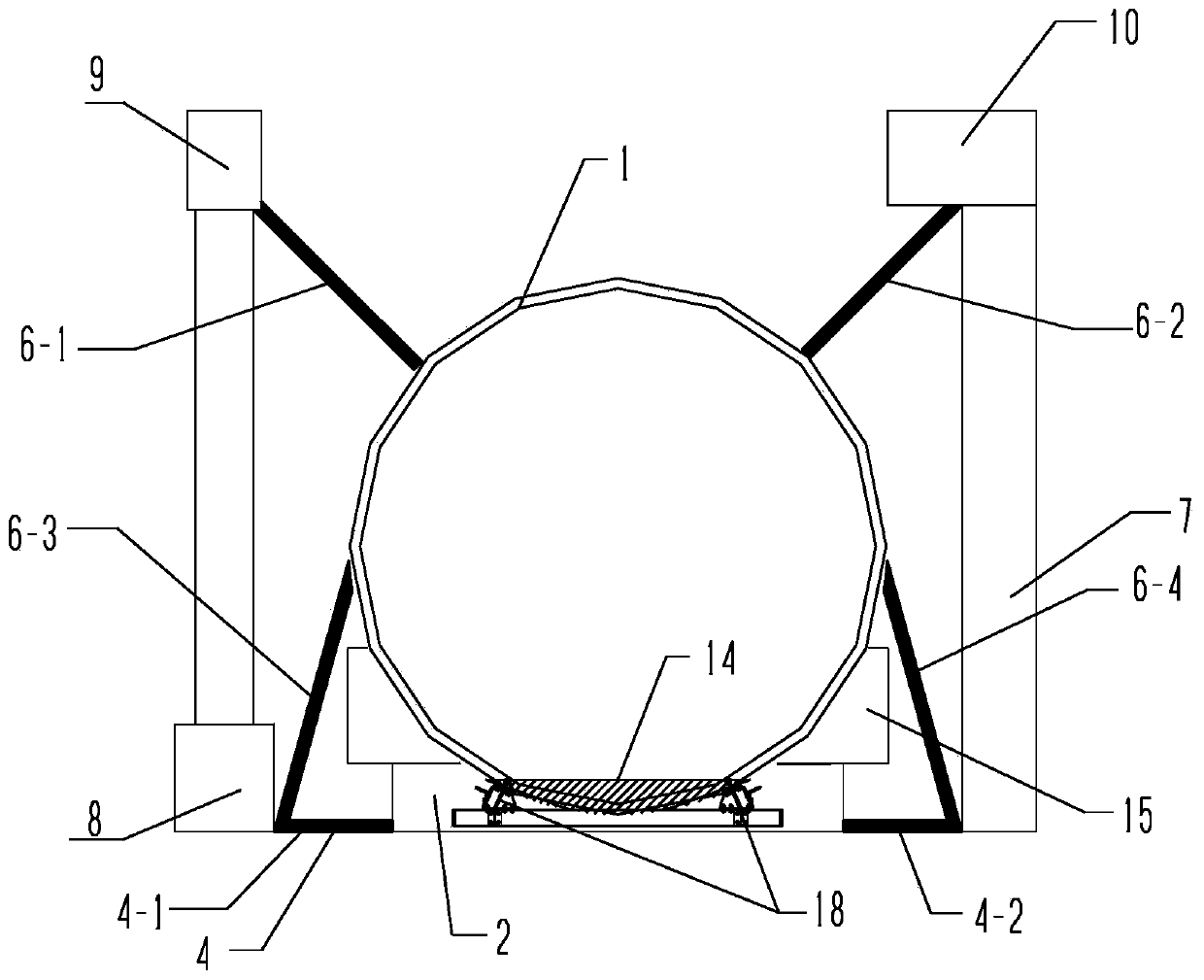

[0035] The present invention will be further described below in conjunction with the embodiments and accompanying drawings. Such as Figure 1 to Figure 2 As shown, the opening door sealing device at the starting end of the shield tunneling machine is characterized in that: the sealing device includes an extended steel ring 1 and an extended steel ring support structure. The extension steel ring 1 is provided with a sealing structure; the steel ring support structure includes a base support 4 arranged on the steel ring base 2, a horse stool support 5 arranged at the bottom groove of the extension steel ring 1 and a set The steel ring supports 6 on both sides of the extended steel ring 1, the horse stool support 5 includes two 20H-shaped steel support rods, and steel plate support pads 15 are respectively provided between the two sides of the bottom of the extended steel ring 1 and the steel ring base 2 . The extended steel ring 1 is placed at the opening of the shield machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com