Chain type fast hoop

A fast and chain-like technology, applied in the direction of connecting components, mechanical equipment, friction-clamped detachable fasteners, etc., can solve the problem of increased workload and safety hazards, renovation or increase of platforms, easy to fall off of installation holes, etc. problems, to achieve the effect of enhancing safety protection, stabilizing anti-corrosion ability, and reducing own weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The structures involved in the present invention or the technical terms used are further described below. These descriptions are only used as examples to illustrate how the present invention is implemented, and do not constitute any limitation to the present invention.

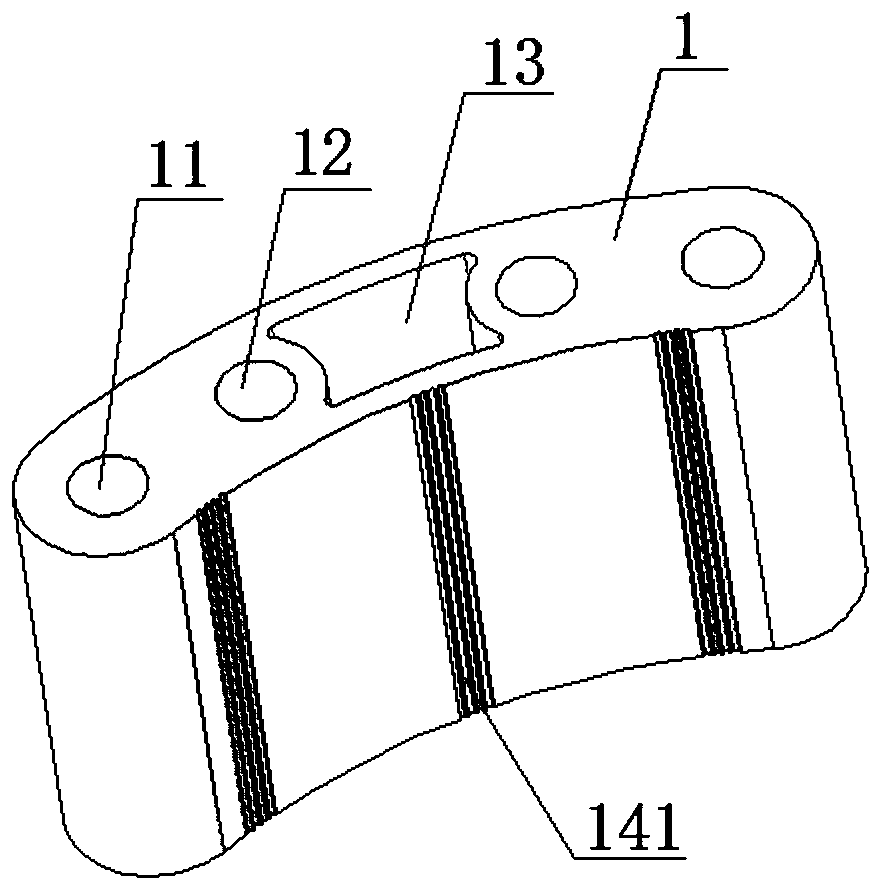

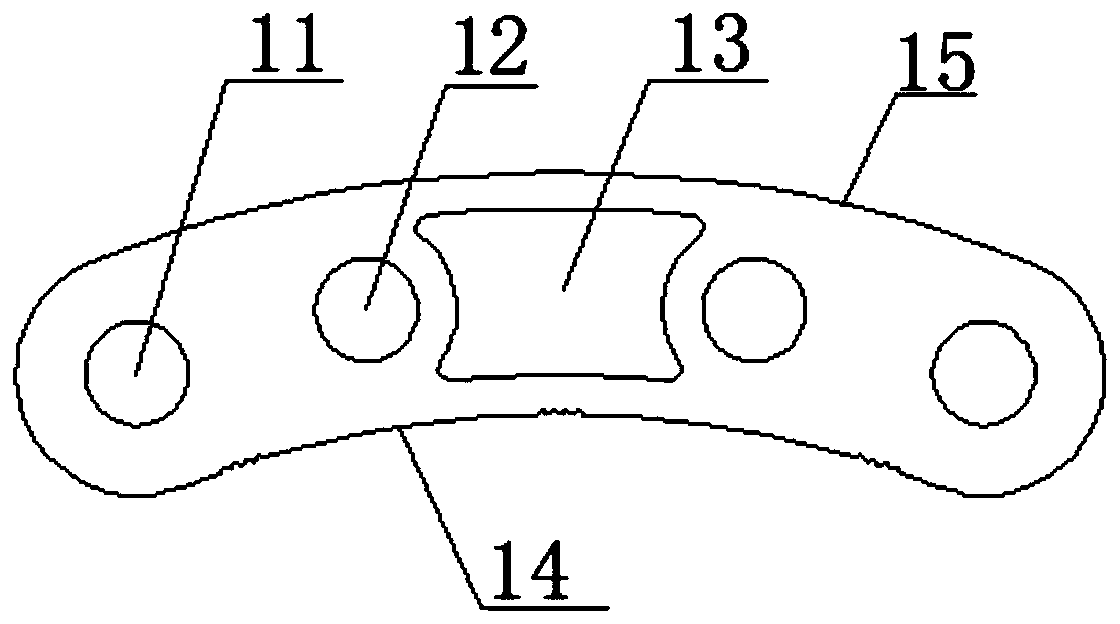

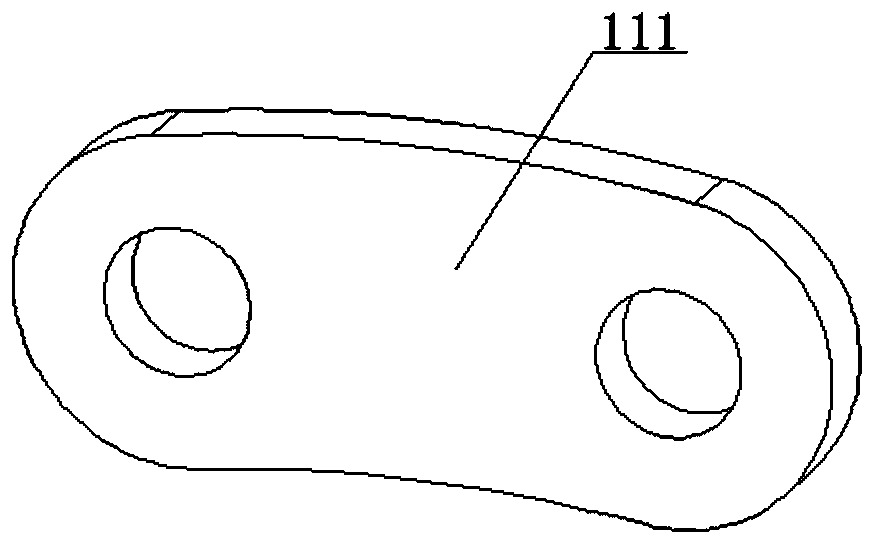

[0036] The existing chain-type fast hoop includes a locking mechanism and a plurality of hoop units, the plurality of hoop units are connected end to end, installed on the installation tower, and then the hoop is locked by the locking mechanism. By adding or reducing hoop units, the installation needs of different types and sizes of installation towers can be met. The chain-type fast hoop generally has a structure for connecting the support arm, the support arm is used to fix the holding rod, and the holding rod is used to install the antenna equipment.

[0037] The traditional hoop unit is provided with mounting holes for connecting the arms on its outer wall. In fact, with this arrangement, the weigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com