Curtain type regenerative burner for forging heating furnace

A forging heating and heat storage technology, which is applied in forging furnaces, lighting and heating equipment, furnaces, etc., can solve the problems of workpiece ablation and large heat loss, and achieve the effects of ensuring switching, heat loss, and heat storage effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

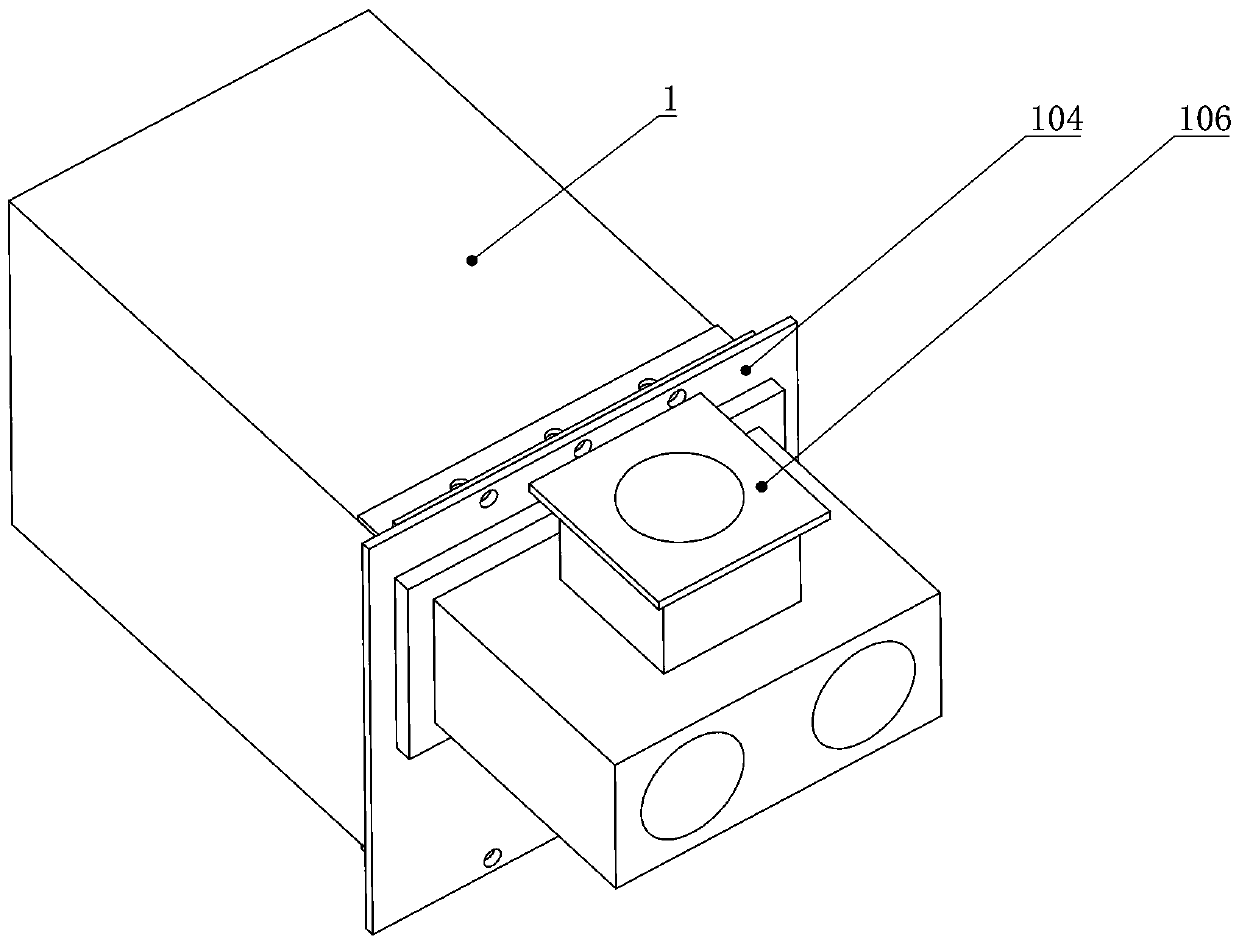

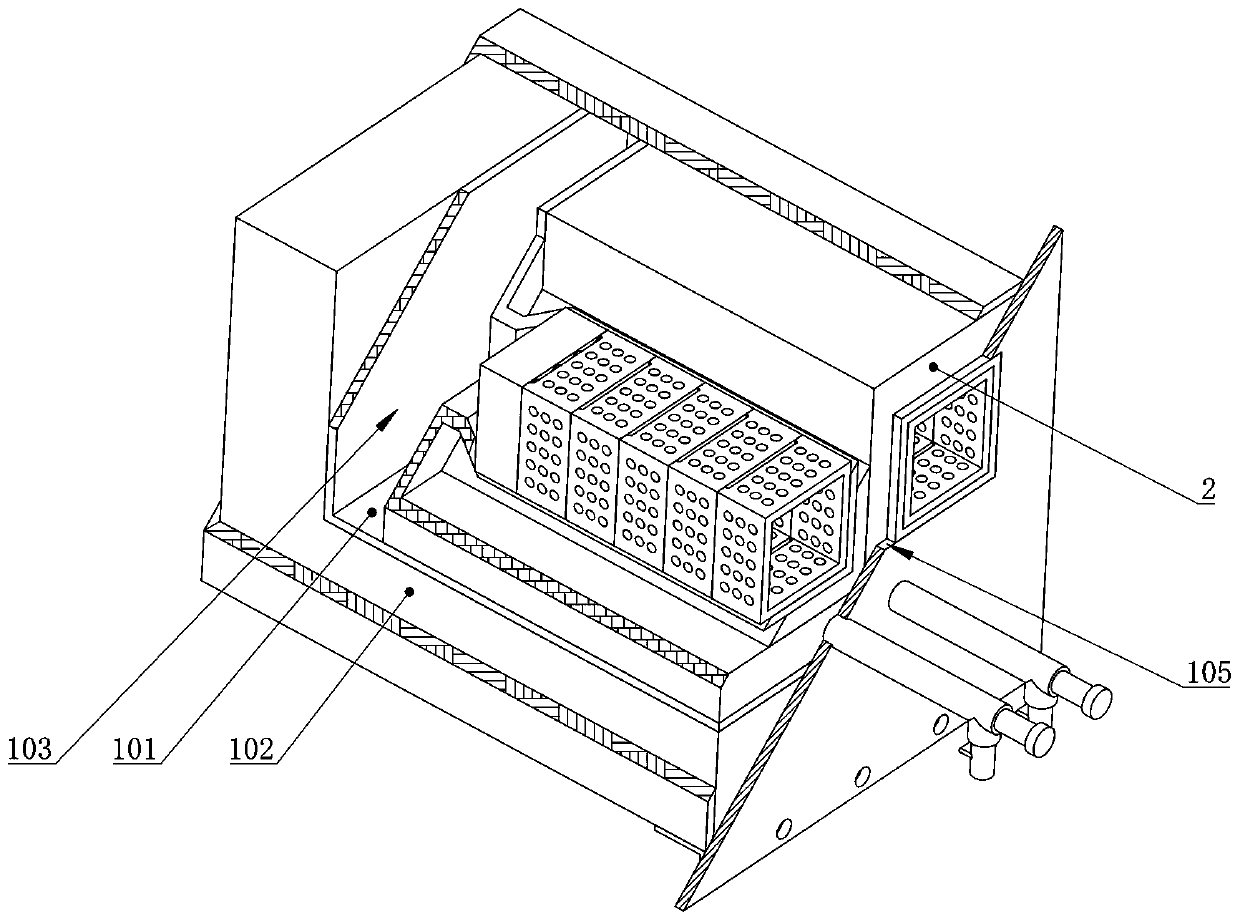

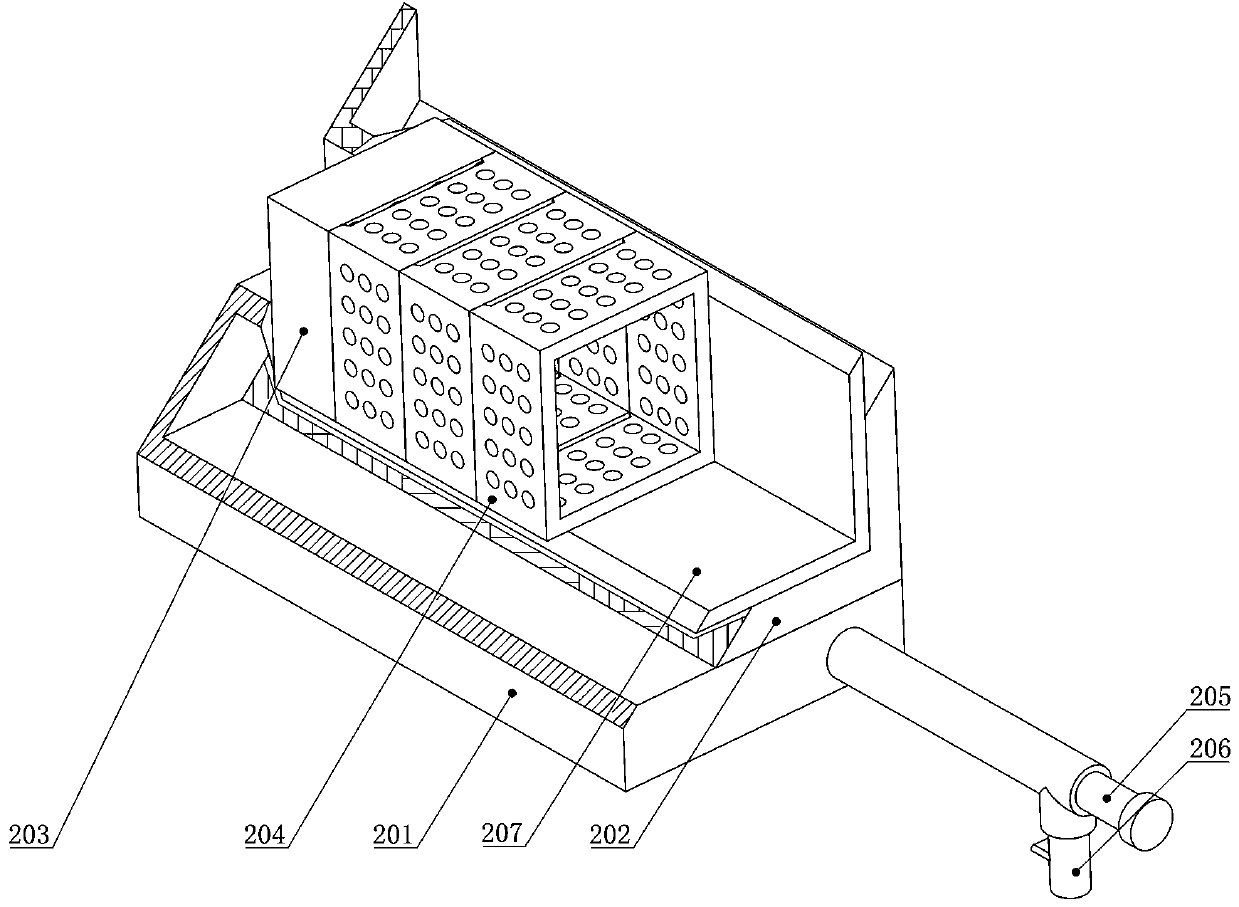

[0015] Specific implementation method: combined Figure 1-4 As shown, it includes a box body 1; the inner side of the box body 1 is provided with an L-shaped partition 101; welding is used between the L-shaped partition 101 and the box body 1; the box body 1 and the The first pressure-resistant compensation blanket 102 is filled between the L-shaped partitions 101; two groups of regenerative burners 2 are arranged at the front of the L-shaped partition 101; the regenerative burners 2 and the L-shaped partition Between 101 is a combustion chamber 103; the outside of the box 1 is provided with an end cover plate 104; the regenerative burner 2 includes a support body 201, a second compression compensation blanket 202, a fire block 203, and a heat storage body 204 , ignition burner 205 and gas pipe 206; welding is adopted between the support body 201 and the box body 1; a square through pipe 207 is provided on the top of the support body 201; 201 is welded; the second pressure-re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com