Heat pump system, control method and heat pump drying device

A technology of heat pump system and control method, which is applied in the direction of drying gas arrangement, refrigeration and liquefaction, local stirring dryer, etc., can solve the problems such as inability to dry, achieve the effect of improving energy efficiency, avoiding the slow heating process, and ensuring the continuous heating process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

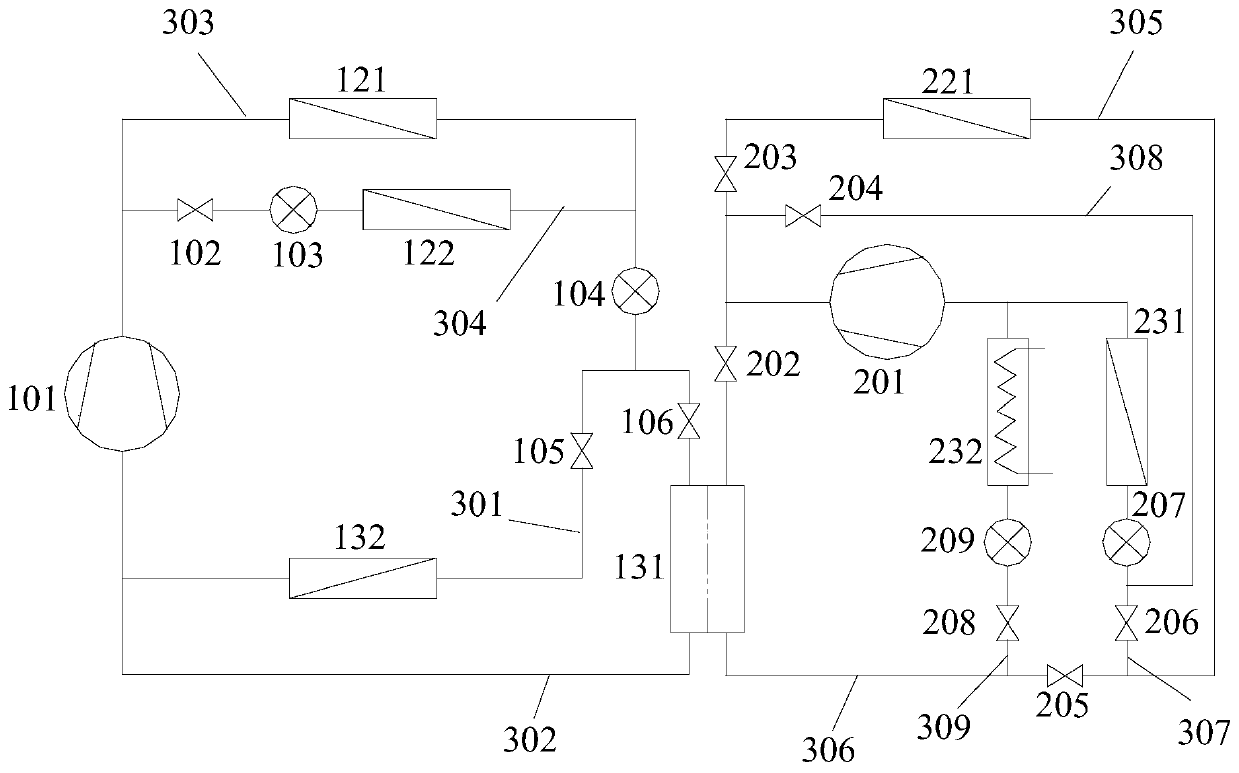

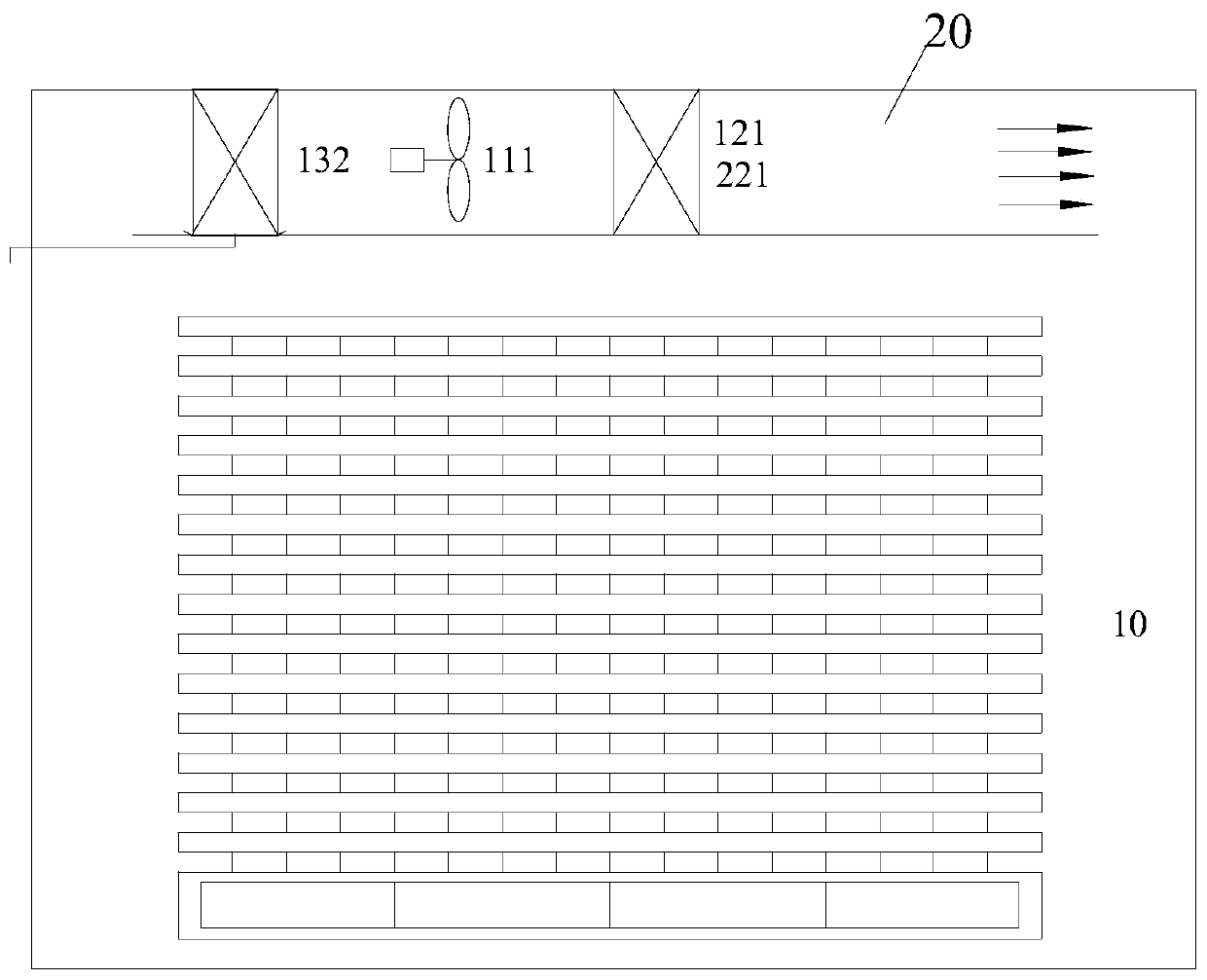

[0051] Such as Figure 1-2 As shown, the present invention provides a heat pump system that can be used to dry materials in a drying room, which includes:

[0052] The first refrigeration cycle system includes a first compressor 101, a first condenser 121, a first evaporator 132, and a heat exchanger 131, and the heat exchanger 131 is arranged in parallel at both ends of the first evaporator 132, The first refrigeration cycle system is filled with a first refrigerant;

[0053] The second refrigeration cycle system includes a second compressor 201, a second condenser 221, a second evaporator 231, and the heat exchanger 131, and the heat exchanger 131 is arranged in parallel on both ends of the second condenser 221. end, and the first refrigerating cycle system and the second refrigerating cycle system exchange heat through the heat exchanger 131, the second refrigerating cycle system is filled with the second refrigerant, and the first refrigerating cycle system The boiling p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com