Energy-saving, dust-settling and emission-reducing device of condensing fluidizedbed

A floating bed and condensing technology, which is applied in the direction of using liquid separation agent, lighting and heating equipment, and separation of dispersed particles, can solve the problems of unutilization, dust removal and desulfurization, etc., to save resources, prevent low-temperature corrosion, and reduce emissions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

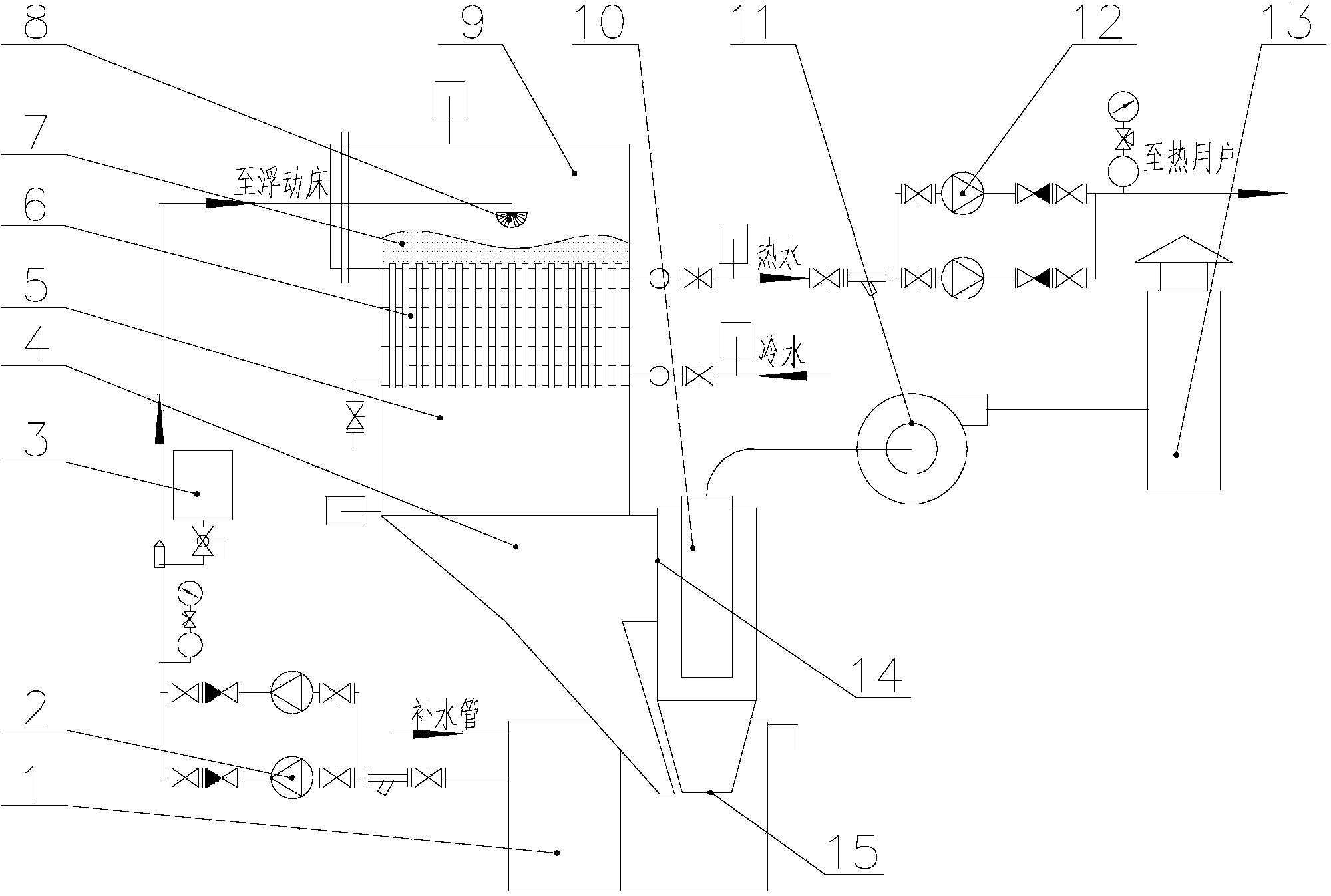

[0018] Below in conjunction with accompanying drawing, the present invention will be further described as follows:

[0019] as attached figure 1 As shown, the present invention comprises: inlet smoke chamber 9, floating bed heat exchanger 6, outlet smoke chamber 5, dust reduction chamber 4 and dust reduction filter pool 1, inlet smoke chamber 9, floating bed heat exchanger 6, outlet smoke chamber 5 , the dust-suppression chamber 4 and the dust-suppression filter tank 1 are connected sequentially from top to bottom, and a floating bed generator 8 is installed in the inlet smoke chamber 9. The floating bed generator 8 can be a variety of structures such as a nozzle or a rotary cup. The generator 8 is connected to the dust-reducing filter tank 1 through a pipeline, and the dust-reducing filter tank 1 is filled with water, and the upper end of the dust-reducing filter tank 1 is connected to the water supply pipe, and the pipeline between the floating bed generator 8 and the dust-r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com