Finned tube evaporator for air-cooled refrigerator and air-cooled refrigerator

A technology for air-cooled refrigerators and evaporators, used in evaporators/condensers, applications, refrigerators, etc., can solve the problems of asynchronous defrosting process, large heat loss, reduced defrosting efficiency, etc., and increase the number of windward pipes. , reduce defrosting energy consumption, improve the effect of defrosting synchronization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0022] In the description of the present invention, it should be understood that the embodiments described in the present invention are exemplary, and the specific parameters appearing in the description of the embodiments are only for the convenience of describing the present invention, and should not be construed as limiting the present invention.

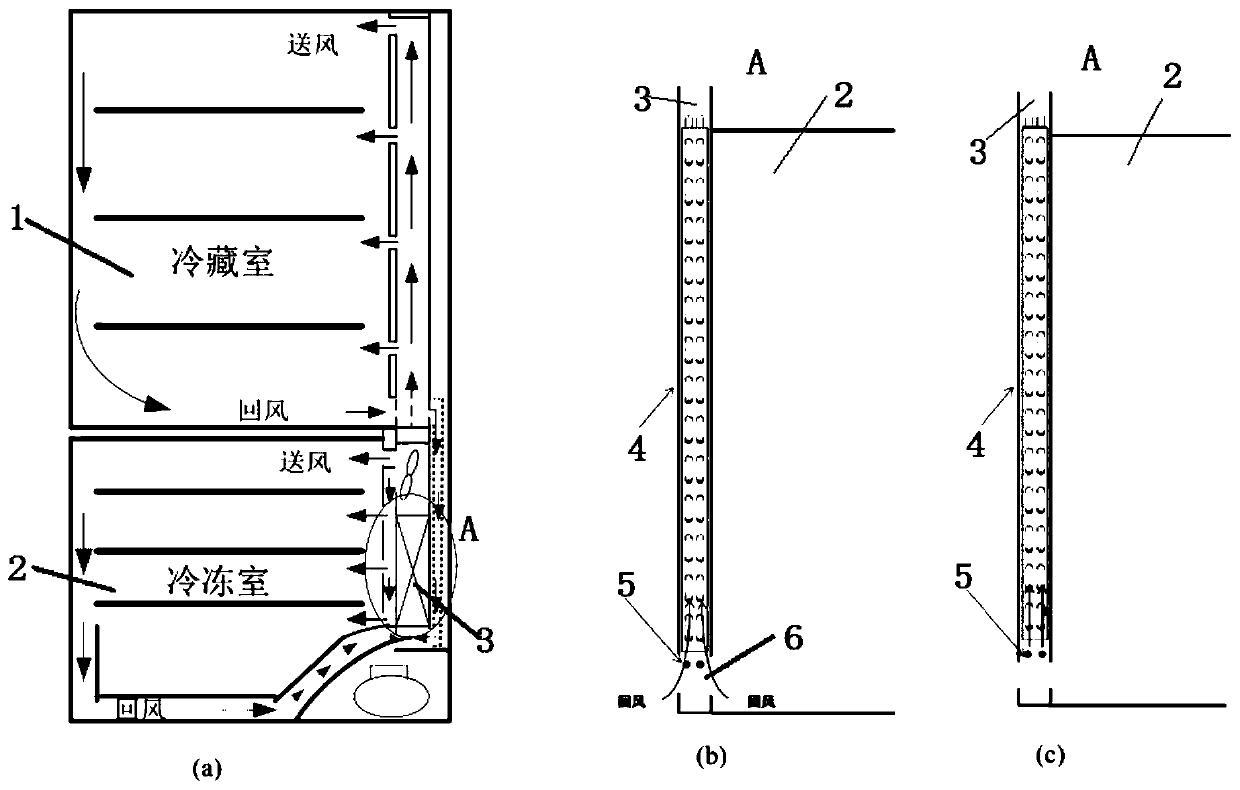

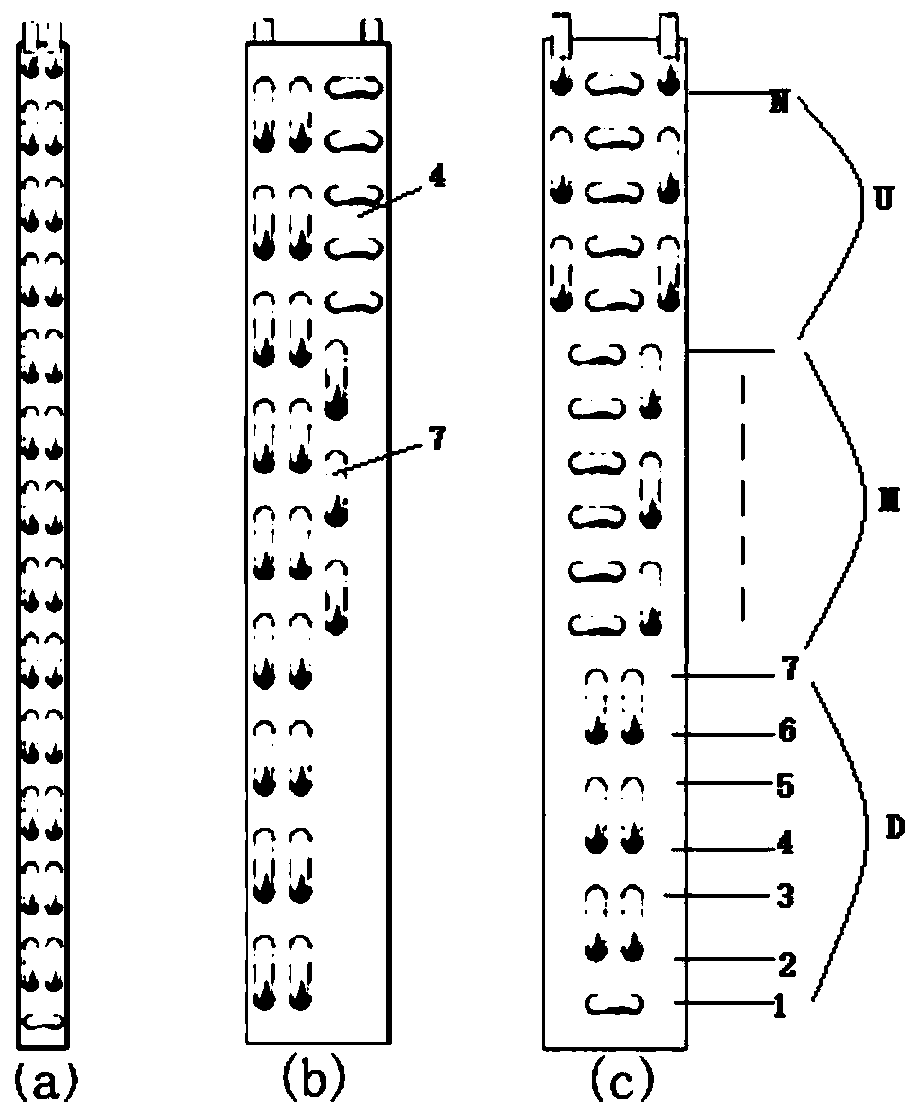

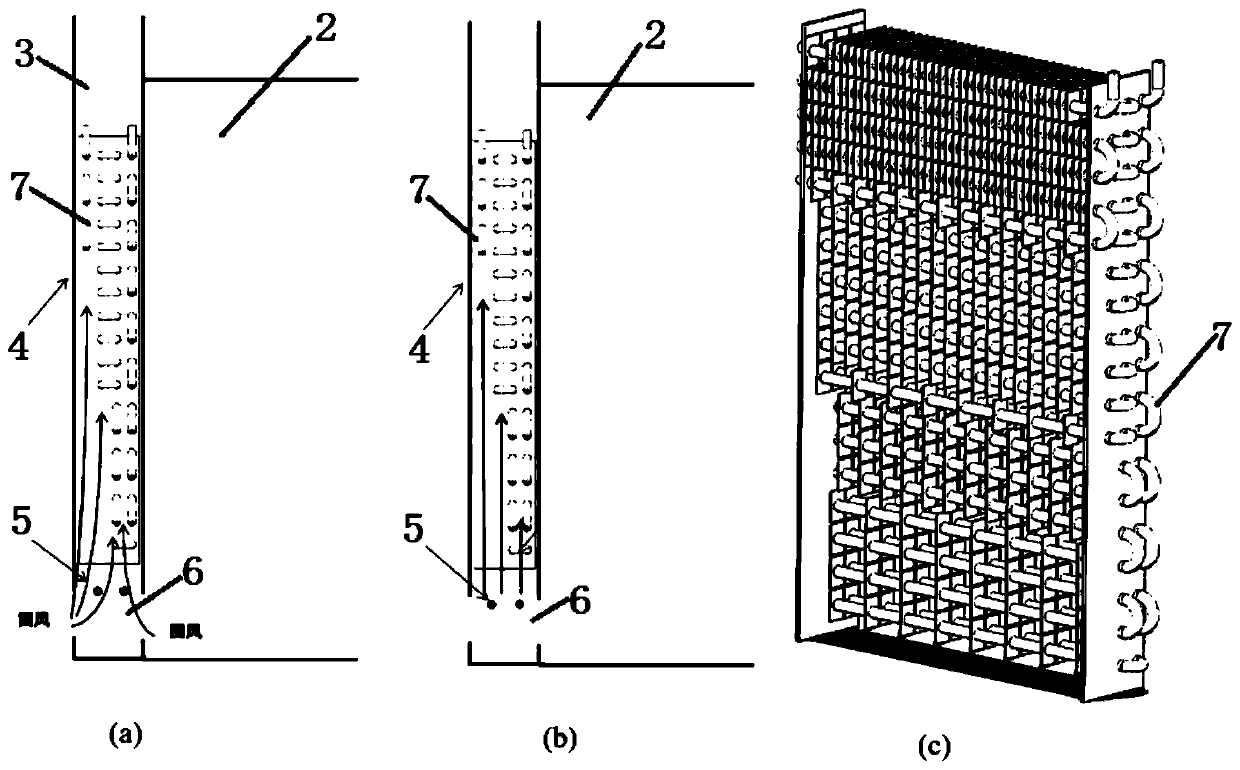

[0023] figure 1 (a) is a schematic diagram of a typical air-cooled refrigerator structure. The evaporator return air from each compartment of the refrigerator flows into the evaporator from the bottom of the evaporator, and after being cooled by the evaporator, it is sent to each compartment, so as to achieve the purpose of cooling the goods stored in the compartment. During the cooling process, the moisture in the humid air will condense into frost on the surface of the evaporator. The commonly used ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com