TMR sensor, and preparation method and resistance value adjusting method thereof

An adjustment method and sensor technology, applied in instruments, measuring magnetic variables, measuring devices, etc., can solve the problems of resistance deviation of TMR sensing unit and increase the difficulty of sensor circuit operation, so as to reduce the difficulty of zero adjustment and expand the scope of application. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the above and other objects, features and advantages of the present invention more apparent, the following specifically cites the embodiments of the present invention, together with the accompanying drawings, for a detailed description as follows.

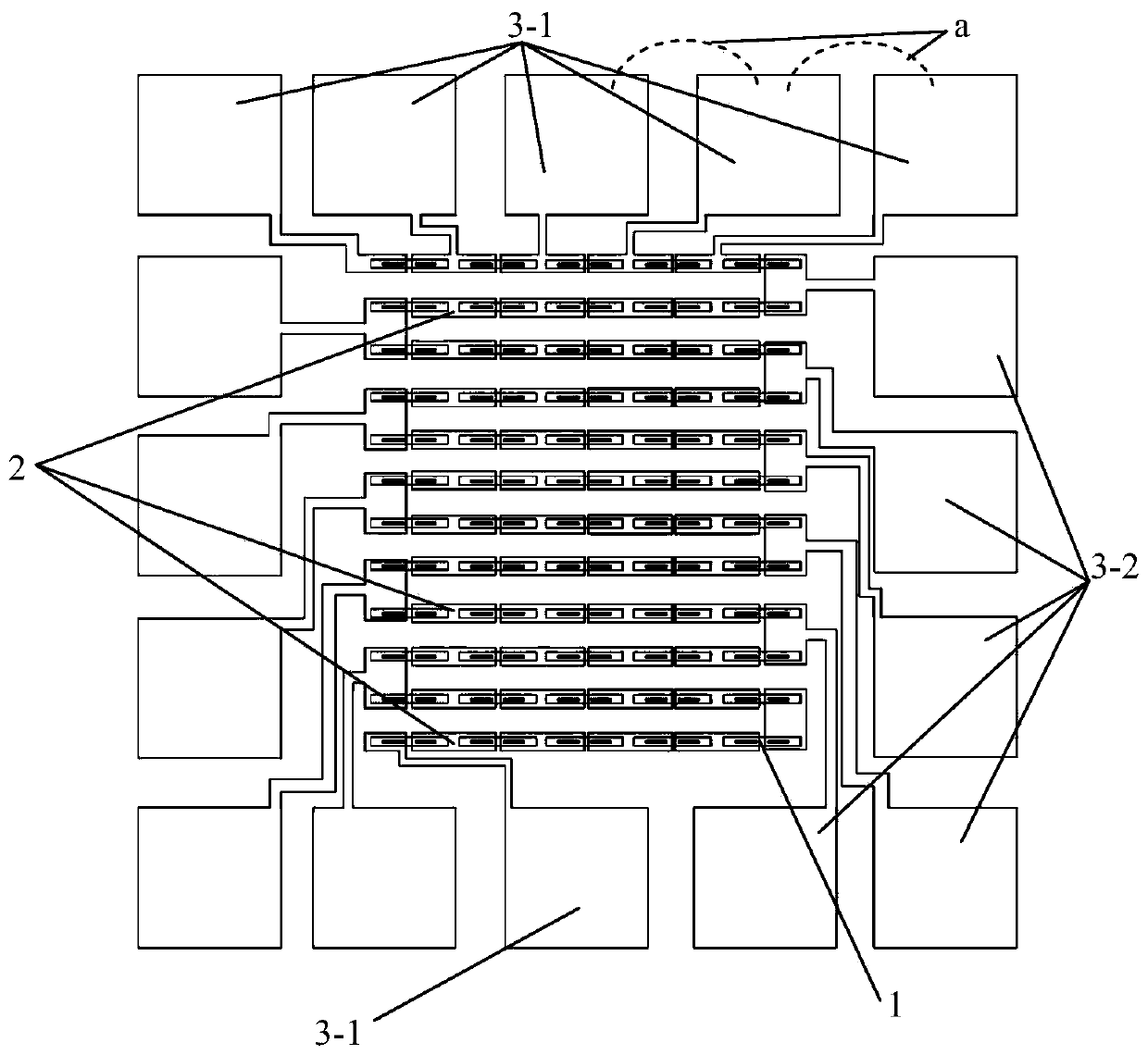

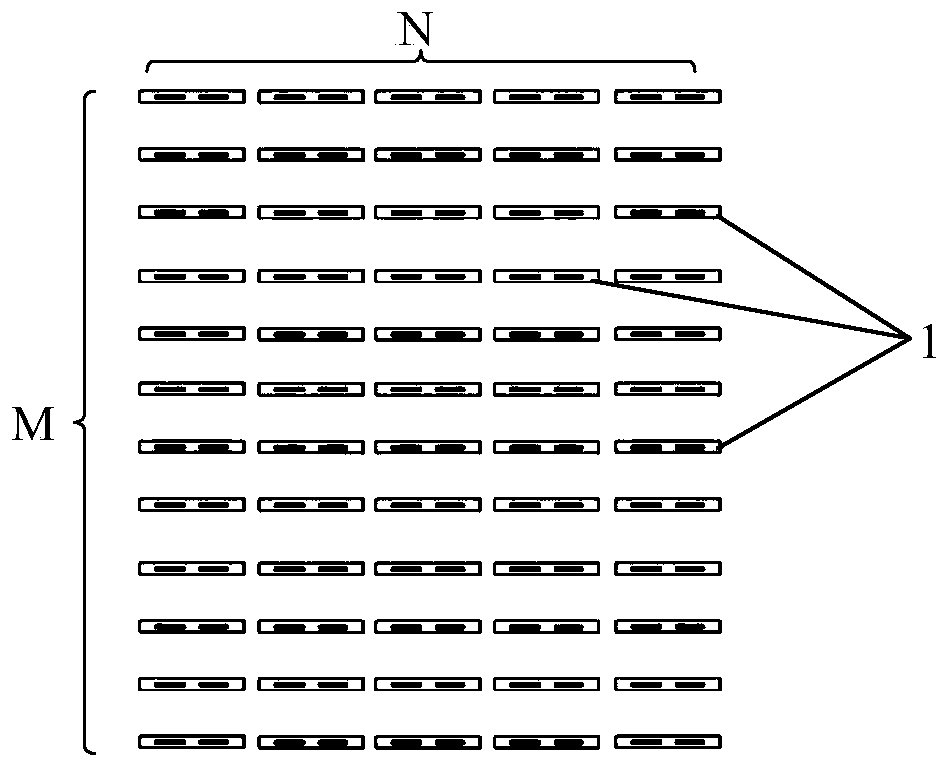

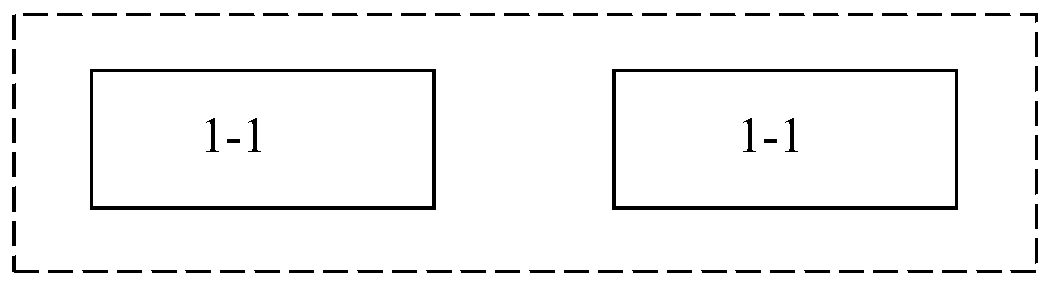

[0029] like figure 1 As shown, the TMR sensor of this embodiment includes an MTJ array disposed on an insulating substrate (not shown), connecting electrodes 2 , adjusting electrodes and peripheral circuits (not shown). The MTJ array is composed of a plurality of MTJ units 1, and the MTJ units 1 are arranged in the form of M rows×N columns to form an array ( figure 2 ), M and N are integers greater than zero. like image 3 As shown, one MTJ unit 1 includes two MTJ structures 1-1 connected in series, and the MTJ structures 1-1 in this embodiment are connected in series through the bottom electrode grown directly on the insulating substrate. MTJ structure 1-1 is a conventional structure, such as Figure 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com