Dust-proof ventilation power control cabinet

A power control cabinet and dust-proof technology, which is applied in the cooling/ventilation of substation/switchgear, substation/power distribution device shell, etc., can solve the problem of unable to meet the needs of power equipment installation, and the internal space of the cabinet cannot be adjusted and installed The frame structure cannot be adjusted, etc., to achieve the effects of prolonging life, rapid heat dissipation, and reducing maintenance times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

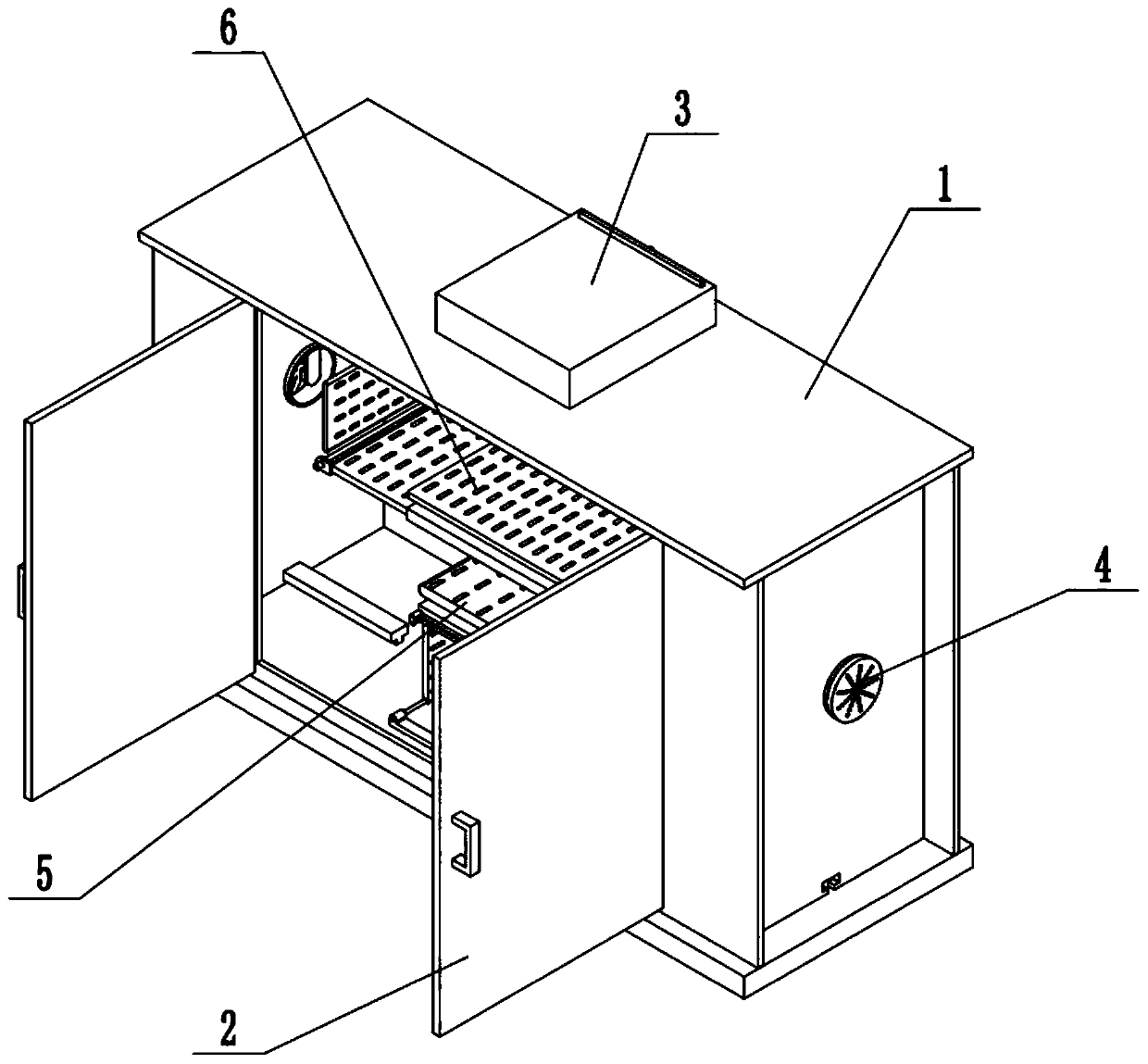

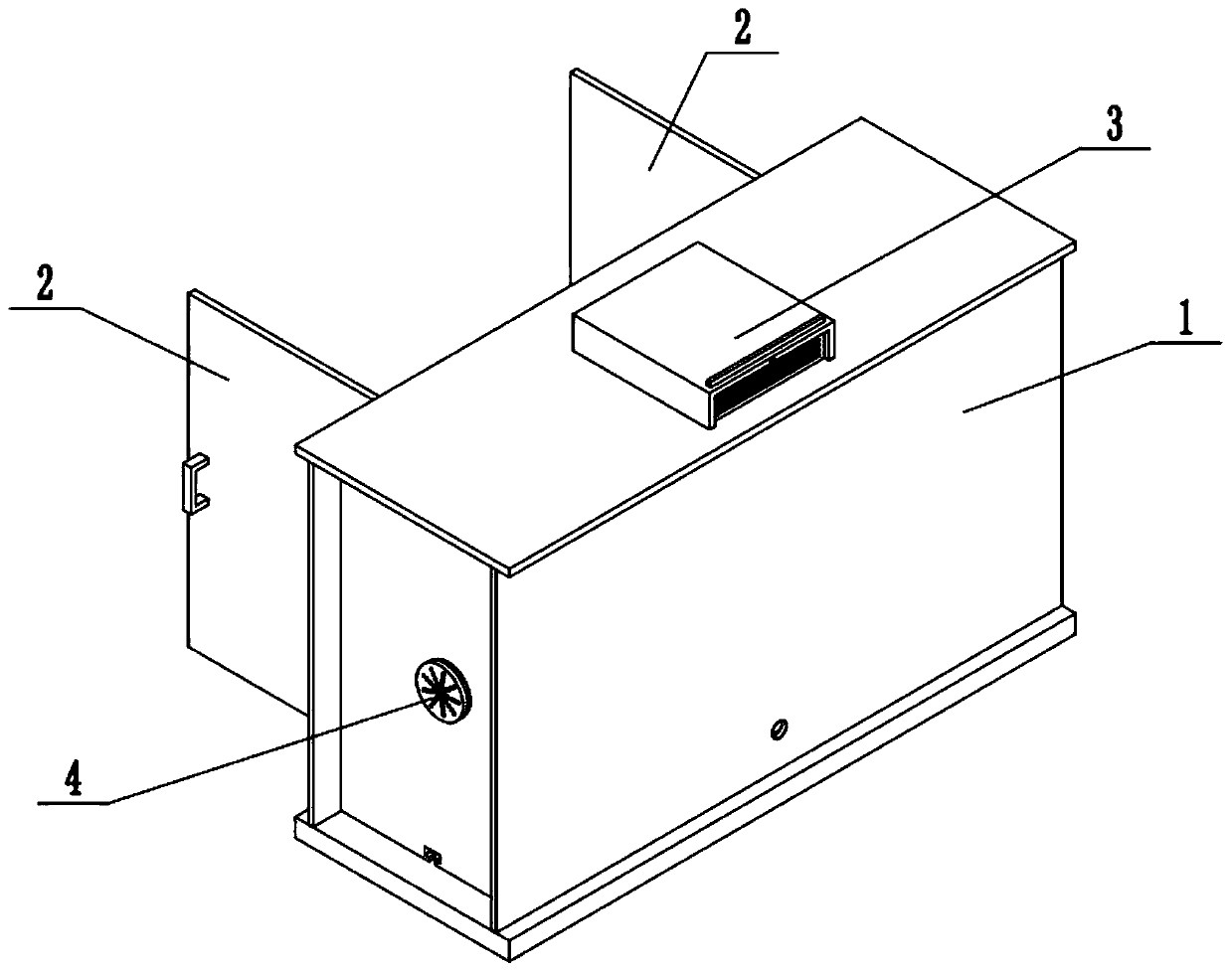

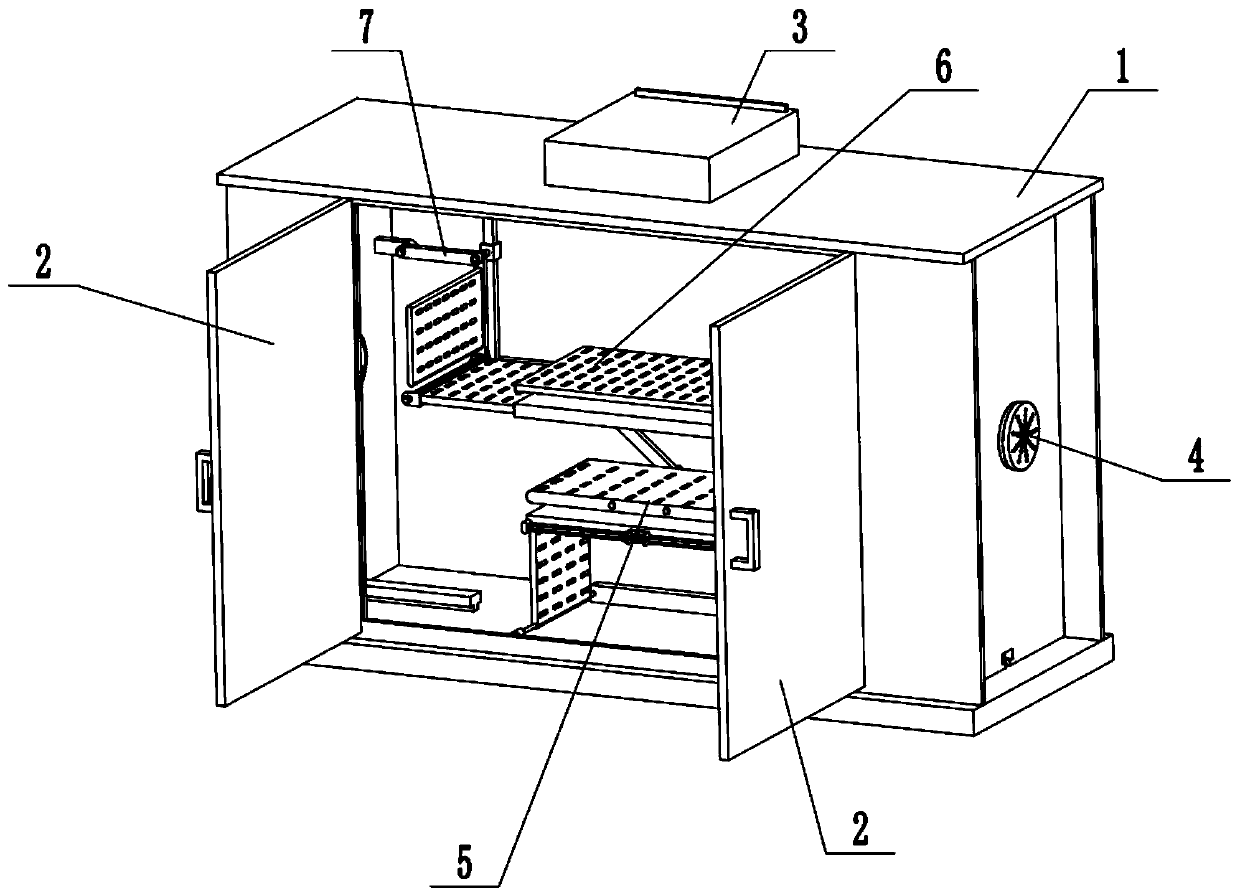

[0027] Such as Figure 1-9 As shown, a dust-proof and ventilated power control cabinet includes a cabinet body 1, a door panel 2, a dust-proof intake mechanism 3, an exhaust ventilation mechanism 4, a lower mounting frame 5, an upper mounting frame 6 and a push-pull frame 7. The cabinet Body 1 includes top board 1-1, bottom board 1-2, cabinet door board 1-3, back board 1-4, side board 1-5 and T-shaped slide rail 1-6; said cabinet door board 1-3 and back board 1 -4 are respectively fixedly connected to the front and rear ends of the top surface of the bottom plate 1-2; the middle end of the top surface of the bottom plate 1-2 is fixedly connected to the left and right two T-shaped slide rails 1-6; Two side plates 1-5 are respectively slidably connected to a T-shaped slide rail 1-6; the top surface, front side, bottom surface and rear side of the side plate 1-5 are respectively connected with the top plate 1-1, the cabinet The door panel 1-3, the bottom panel 1-2 and the back p...

specific Embodiment approach 2

[0029] Such as Figure 1-9 As shown, the backboard 1-4 is provided with cable through holes. The cable through hole is used for external connection of the cables of the electric equipment installed in the cabinet body 1 .

specific Embodiment approach 3

[0030] Such as Figure 1-9 As shown, the dust-proof air intake mechanism 3 includes an air intake box 3-1 and a dust blocking filter plate 3-2; the air intake box 3-1 is fixedly connected on the top plate 1-1, and the air intake box 3-1 A plurality of air intake holes are connected; the rear side and the bottom surface of the air intake box 3-1 are hollow structures; the rear end of the top surface of the air intake box 3-1 is provided with a rectangular through hole; the dust blocking filter plate 3-2 Slip-fit connection in the rectangular through-hole.

[0031] When the dust-proof air intake mechanism 3 is in use, when the exhaust ventilation mechanism 4 works, when the exhaust ventilation mechanism 4 extracts the hot air inside the cabinet body 1, the outside air can enter into the air intake box 3-1. into the cabinet body 1 through the air intake hole to complete the discharge of hot air and the entry of normal temperature air, and when the outside air enters the air in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com