Fault diagnosis and processing method for current sensor of permanent magnet synchronous motor control system

A permanent magnet synchronous motor and current sensor technology, applied in control systems, vector control systems, motor generator control, etc., can solve problems such as poor effect accuracy, inability to run when stopped, and out-of-control electric vehicles, so as to improve the driving experience. , to ensure the effect of safe driving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

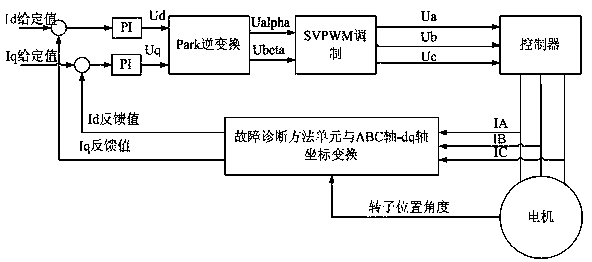

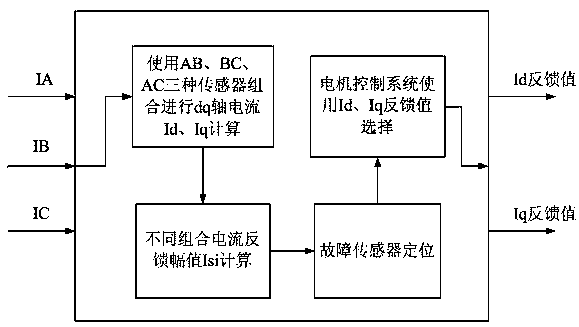

[0031] Example figure 1 and figure 2 As shown, the permanent magnet synchronous motor control system adopts the PI vector control system. The motor three-phase current IA, IB, and IC output the actual control Id feedback value and Iq feedback value after passing through the fault diagnosis method unit. The deviation of the value is input into the PI controller and then outputs Ud and Uq; Ud and Uq are converted into Ualpha and Ubeta after Park inverse transformation, and then output Ua, Ub, and Uc through SVPWM modulation to act on the motor controller.

[0032] Such as figure 2 As shown, in the above permanent magnet synchronous motor control system, the current sensor fault diagnosis and processing method includes the following steps:

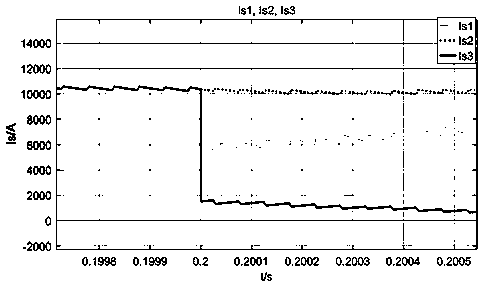

[0033] Step 1. Three current sensors are used to sample the three-phase stator current of the motor respectively to form a closed-loop vector control system. The three-phase current of the stator is obtained in real time through the three...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com