Frozen noodles and preparation method thereof

A noodle and flour technology, which is applied in food science, food preservation, application, etc., can solve the problems of high-quality products that cannot be maintained for a long time, rapid product performance degradation, and high additive content, etc., and achieve good appearance, smooth surface, and quality Enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] In some embodiments of the present invention, the preparation method of quick-frozen noodles comprises the steps:

[0022] (1) Measuring and mixing flour, starch or modified starch, sieving, adding to a vacuum dough mixer, mixing salt, quality improver and water in proportion, the ratio of powder to water is 2:1-4:1.

[0023] (2) Turn on the vacuum kneading machine, fully mix the above-mentioned powder and liquid to form a dough, and the vacuum kneading feature is that the vacuum kneading machine is used for vacuum kneading for 10-20 minutes.

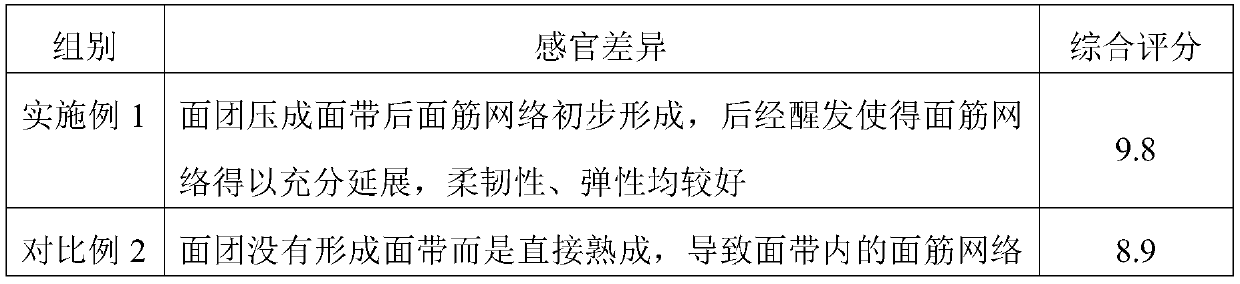

[0024] (3) One-time calendering: the dough is pressed into a dough band with a thickness of 15-20mm through a compound machine, and the upper band is sent into the ripening machine.

[0025] (4) Aging: temperature 20-40°C, humidity 70%-90%, time 15-60 minutes.

[0026] (5) Secondary calendering: the matured noodle strips are calendered in 3 to 5 stages to the required thickness.

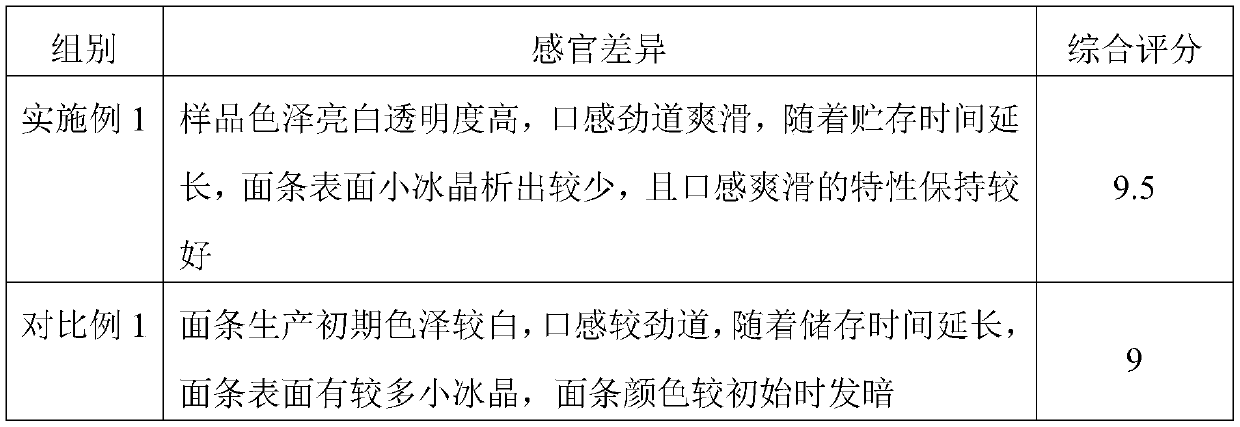

Embodiment 1

[0040] Fully mix 7.5kg of flour and 750g of starch and sieve, add to the vacuum dough mixer, mix 150g of salt, 22.5g of guar gum and 3kg of water in proportion, turn on the vacuum dough mixer and knead the dough for 15 minutes, and knead the dough Press it into 18mm thick noodle strips, then mature them at a temperature of 25°C and a humidity of 75% for 30 minutes, and then go through five stages of continuous rolling to form noodle strips with a thickness of 1.5mm. Boil the noodles at 98°C for 2 minutes, take them out and rinse them in cold water at 4°C for 1 minute, put them in a quick freezer after shaping, freeze them at -30°C for 25 minutes, pack them and put them in a cold storage after quick freezing.

Embodiment 2

[0042] Fully mix 7.5kg of flour and 750g of hydroxypropyl modified starch and sieve, add to a vacuum dough mixer, mix 220g of salt, 22g of guar gum and 3.2kg of water in proportion, turn on the vacuum dough mixer for 15 minutes, and put The reconciled dough is pressed into 18mm thick noodle strips, then aged at 40°C and 80% humidity for 40 minutes, and then passed through three stages of continuous rolling to form noodle strips with a thickness of 2.5mm and cut into round strips with a diameter of 2.5mm , put the noodles into the cooking pot and boil the noodles at 99°C for 10 minutes, take them out and rinse them in cold water at 8°C for 3 minutes, put them in a quick-freezer after shaping, freeze them at -35°C for 30 minutes, pack them and store them in a cold storage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com