Plastic raw material mixing and stirring machine

A mixer and raw material technology, applied in the field of plastic raw material mixing mixer, can solve the problems of uneven mixing, time-consuming and laborious, affecting production efficiency, etc., and achieve the effect of improving production efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

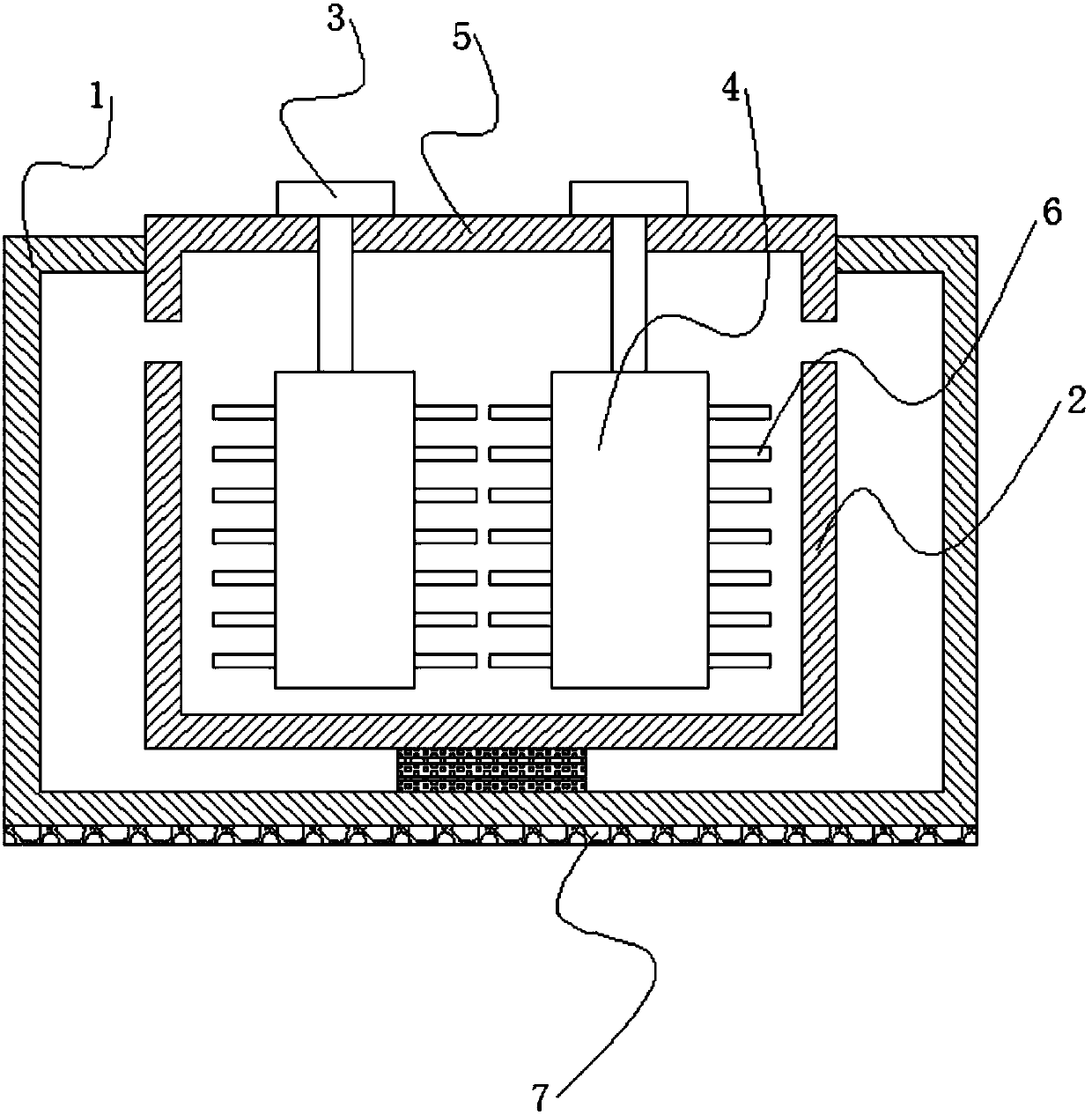

[0012] The invention provides a plastic raw material mixing mixer, comprising: a box shell 1, a box body 2, a motor 3, and a stirring column 4; the box body 2 is fixed inside the box shell 1; the top of the box shell 1 A cover plate 5 is set, and a box body 2 for loading raw materials is arranged inside, and the box body 2 is located below the cover plate 5; two motors are arranged symmetrically on the central axis of the cover plate 5 above the top of the cover plate 5 3. The output end of the motor 3 runs through the cover plate 5 and extends to the inside of the box body 2, the output end of the motor 3 is fixedly connected to the stirring column 4, and the stirring column 4 extends to the lower part of the box body 2; The surface of the stirring column 4 is provided with a stirring blade 6, the stirring blade 6 is a helical stirring blade 6, and ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap