An aviation oxygen generator

An oxygen generator and aviation technology, which is applied in the fields of oxygen preparation, inorganic chemistry, oxygen/ozone/oxide/hydroxide, etc., can solve the problems of low safety, easy detachment of air-guiding hoses, poor heat dissipation function, etc. Wide heat transfer area, good heat transfer effect, improved safety and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

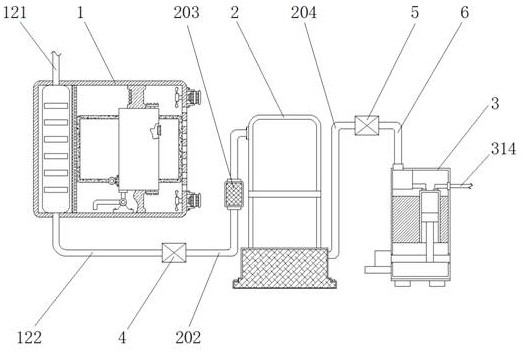

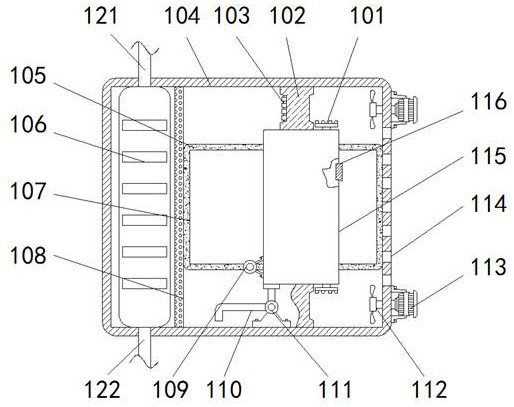

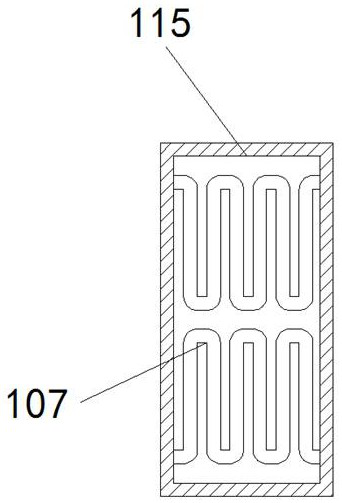

[0050] The embodiment of the present invention provides an aviation oxygen generator, aiming to solve the problems of the current aviation oxygen generators such as poor heat dissipation function, small storage capacity of gas storage device, low safety, long vaporization time, and easy detachment of the gas guide hose. Through the setting of the heat conduction oil 105 and the heat conduction pipe 107, the heat dissipation plate 108 can transfer heat to the heat conduction oil 105, and through the setting of the water tank 115, the heat conduction oil 105 can transfer heat to the water in the water tank 115, and through the setting of the heat dissipation hole 114, it can The heat in the heat transfer oil 105 is dissipated through the heat dissipation holes 114, and the folded heat pipes 107 on the heat dissipation plate 108, inside the water tank 115, and on the inner surface wall of the housing 104 can make the heat transfer area wider, so that the heat The transmission effe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com