Anionic acrylic emulsion containing cationic monomer and preparation method of emulsion

A technology of anionic acrylic acid and cationic monomer, applied in the direction of coating, can solve the problems of unstable polymerization process, damage to the stability of latex particles, limitation of raw material selection, etc. Effect of acid blocking properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

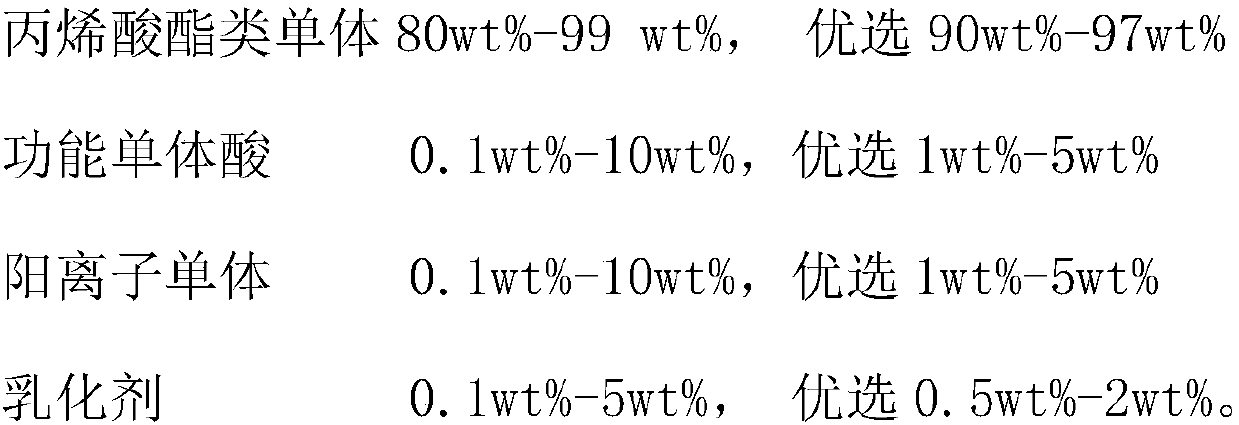

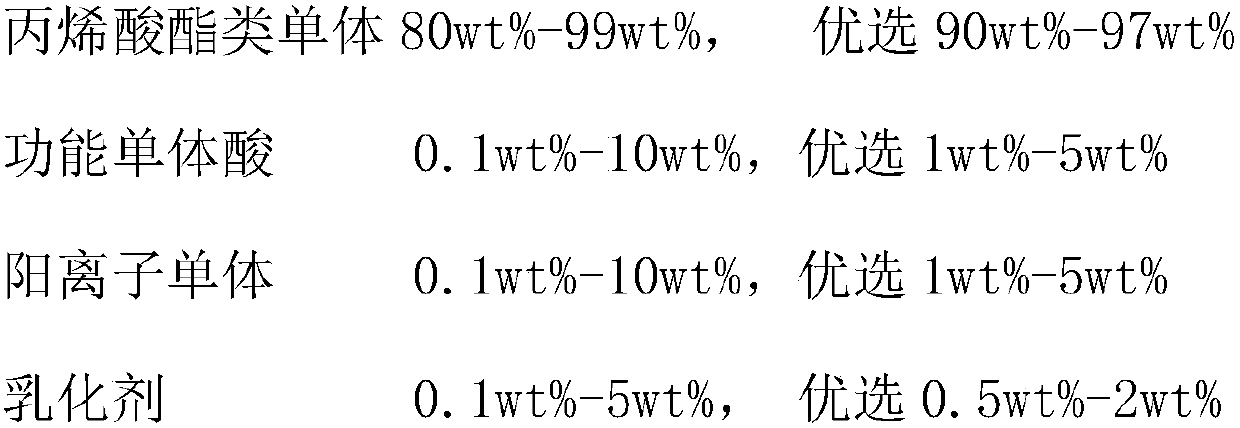

Method used

Image

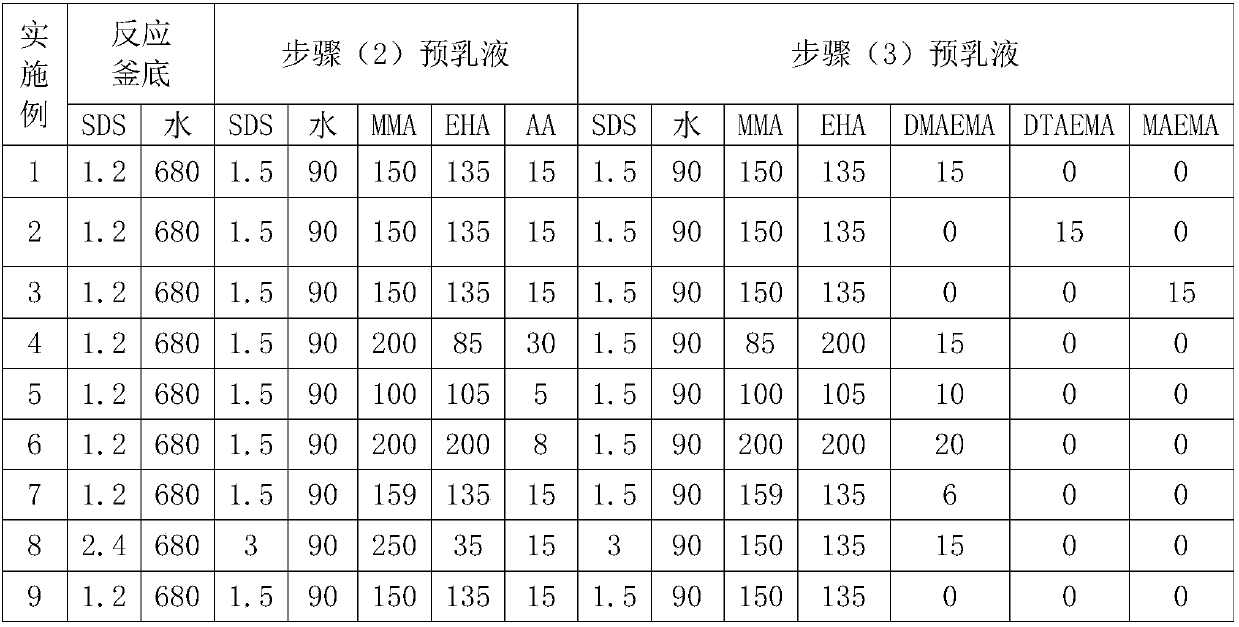

Examples

Embodiment 1

[0035] (1) Add 1.2g sodium lauryl sulfate and 680g water into the reaction kettle, start stirring and heating.

[0036] (2) 150g methyl methacrylate, 135g isooctyl acrylate, 15g acrylic acid, 1.5g sodium lauryl sulfate and 90g deionized water were respectively added to a 1L pre-emulsification kettle for pre-emulsification;

[0037] (3) Add 150g methyl methacrylate, 135g isooctyl acrylate, 15g dimethylaminoethyl methacrylate, 1.5g sodium lauryl sulfate and 90g deionized water to another 1L pre-emulsification tank Pre-emulsification in

[0038] (4) Take 18g of the pre-emulsion in step (2) as seeds and add to the reactor, and when the temperature rises to 85°C, add 1.5g of ammonium persulfate, and the reaction time is 30min;

[0039] (5) When the seed reaction is finished, start to add dropwise the remaining step (2) pre-emulsion and 0.75g ammonium persulfate, and the dropping time is 2h;

[0040] (6) After the dropwise addition, keep warm for 0.5h, then add ammonia water to ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com