Improved diamond compact drill bit

A diamond composite sheet, an improved technology, applied in drill bits, drilling equipment, earth-moving drilling, etc., can solve the problems of low stability, poor impact resistance of drill bits, and small quantities, and achieve excellent performance, reasonable production cost, and improved performance. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0014] In conjunction with the accompanying drawings, the present invention is described in detail.

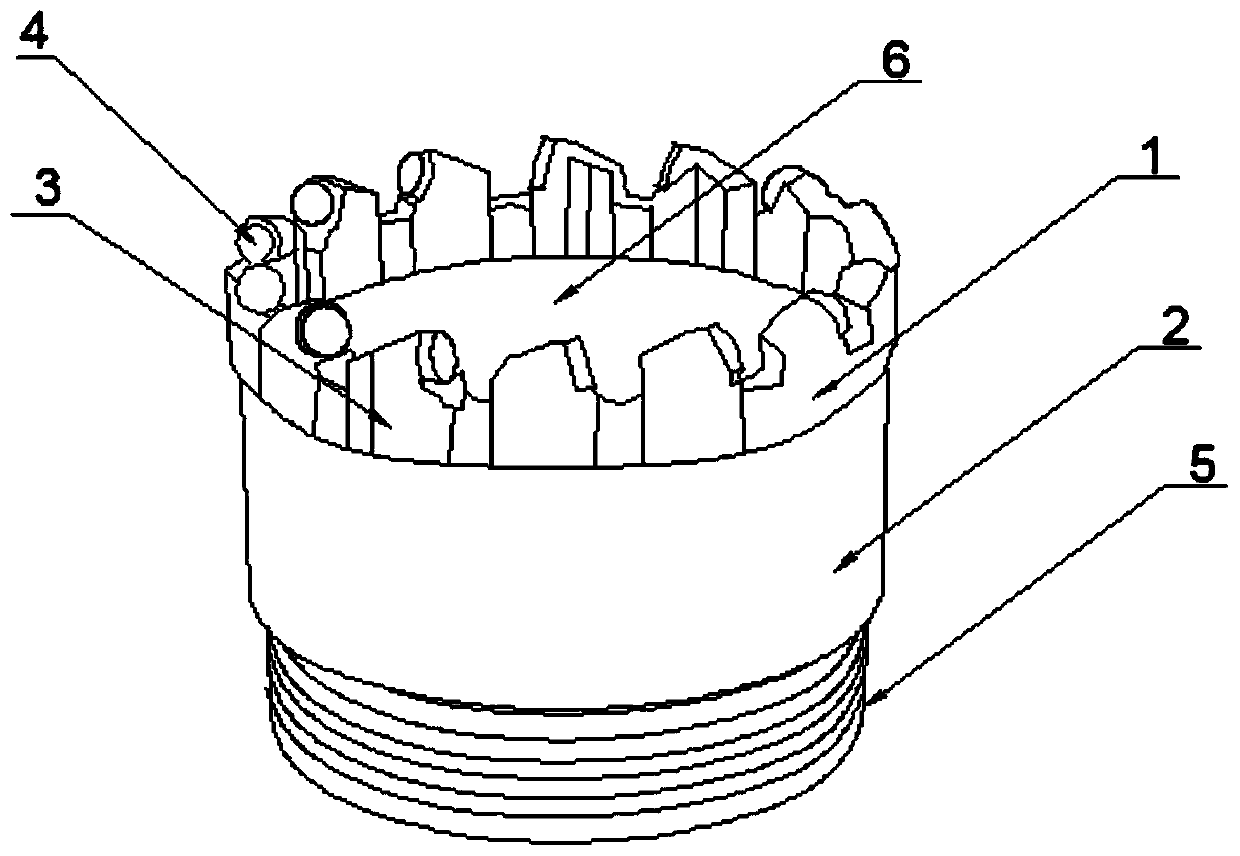

[0015] The present invention provides an improved diamond compact drill bit during specific implementation, including a drill head 1 and a shank 2, the drill head 1 is arranged above the shank 2, and the drill head 1 is provided with a number of drilling holes. Part 3, the front side of the drilling part 3 is provided with a diamond composite sheet 4, the drilling part 3 is connected end to end in sequence, arranged in a circular array, and the bottom of the handle part 2 is provided with a thread 5, the The screw thread 5 and the shank 2 are integrally formed, the center of the drill head 1 and the shank 2 is provided with a through hole 6 , and the diamond composite sheet 4 is welded on the front side of the drill part 3 .

[0016] The diameter of the thre...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap