Block type turbine outer ring connection structure used for gas turbine for ship

A connection structure, gas turbine technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of incongruity between the thermal deformation of the outer ring of the turbine and the casing, difficult to replace the outer ring of the turbine, complicated connection structure, etc. The effect of contact, simple structure and simplified maintenance steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

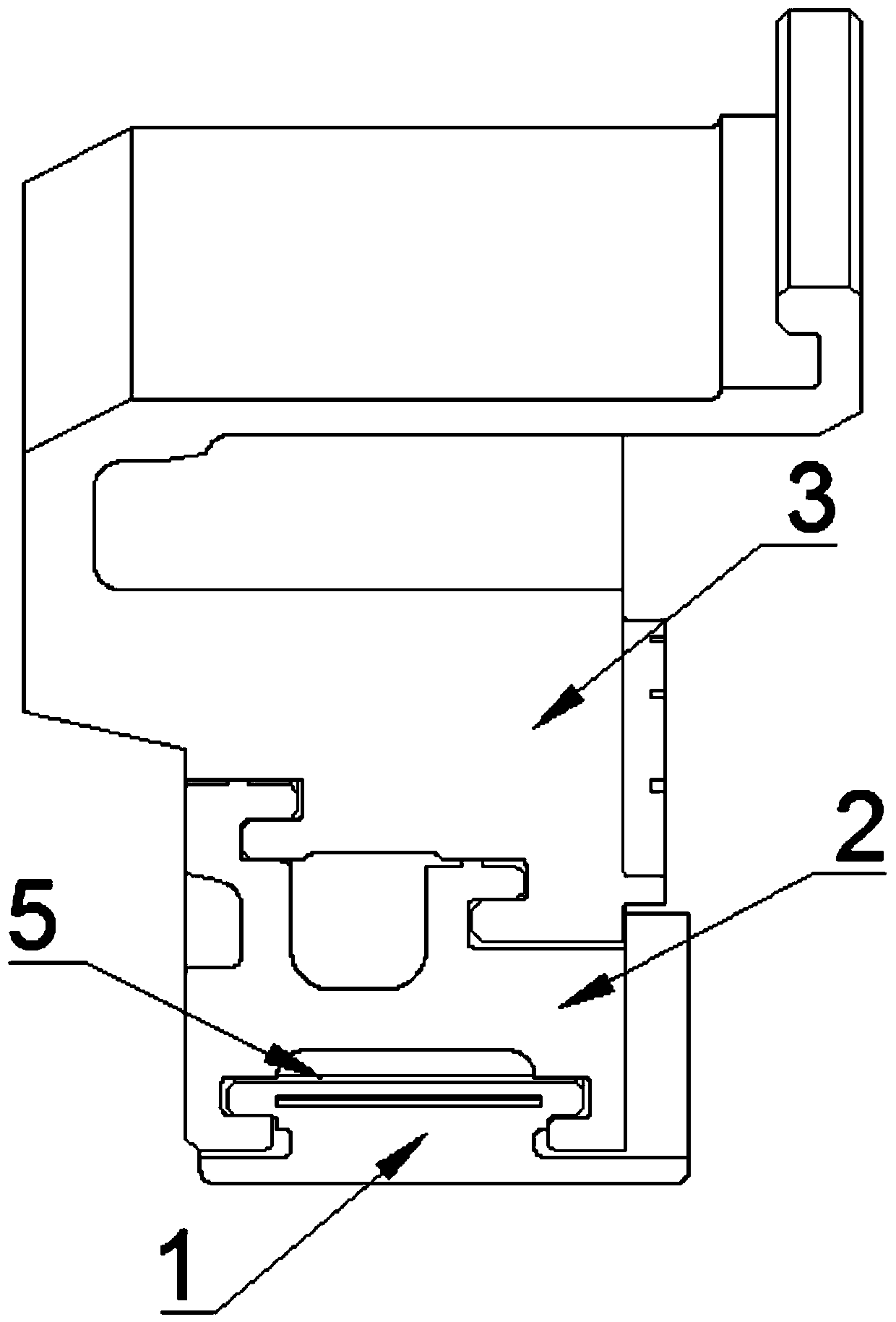

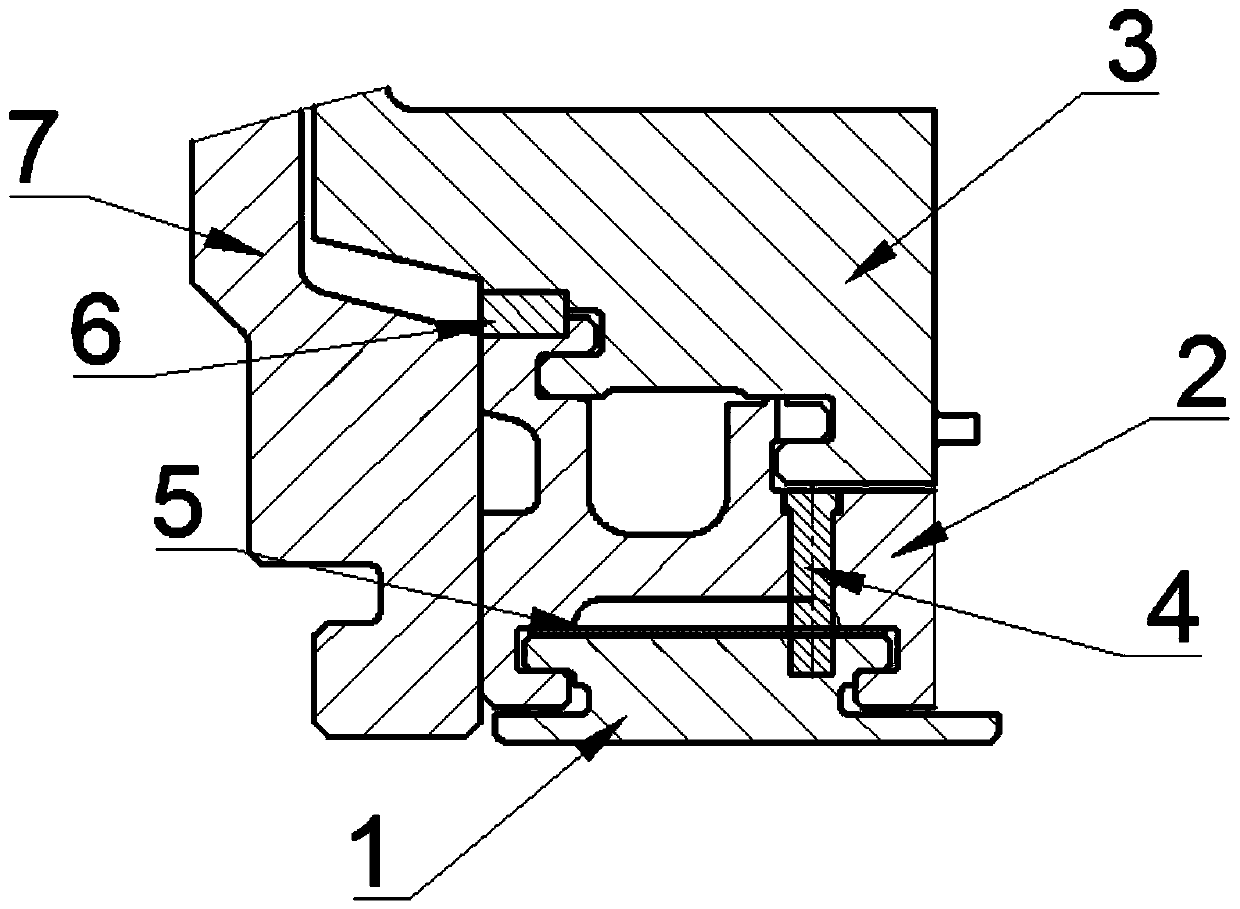

[0030] Specific implementation mode one: combine Figure 1 to Figure 4 Describe this embodiment, a block type turbine outer ring connection structure for marine gas turbines in this embodiment, the block type turbine outer ring connection structure includes casing connection ring 3, N turbine outer ring units and 2N stop pins 6, the casing connecting ring 3 is an integral ring structure, and N turbine outer ring units are evenly distributed on the outer circumference of the casing connecting ring 3, and each turbine outer ring unit is connected to the casing through two stop pins 6 Connecting ring 3 is fixedly connected,

[0031] Each turbine outer ring unit includes a fan-shaped turbine outer ring block 1, a fan-shaped outer ring connecting block 2, a radial pin 4 and an impact plate 5, and N fan-shaped turbine outer ring blocks 1 correspond to N fan-shaped outer ring connecting blocks 2 one-to-one It is set that all the fan-shaped turbine outer ring blocks 1 form a turbine ...

specific Embodiment approach 2

[0037] Specific implementation mode two: combination figure 2 and Figure 4 Describe this embodiment, the rear end of the fan-shaped turbine outer ring block 1 of this embodiment, the fourth hook 2-4 at the rear end of the fan-shaped outer ring connection block 2, the rear part of the fan-shaped outer ring connection block 2 and the impact plate 5 Both are provided with notches for accommodating radial pins 4 . In this way, the outer ring of the turbine is connected to the turbine connector through the hook structure, and is positioned circumferentially by the radial pins 4 . Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

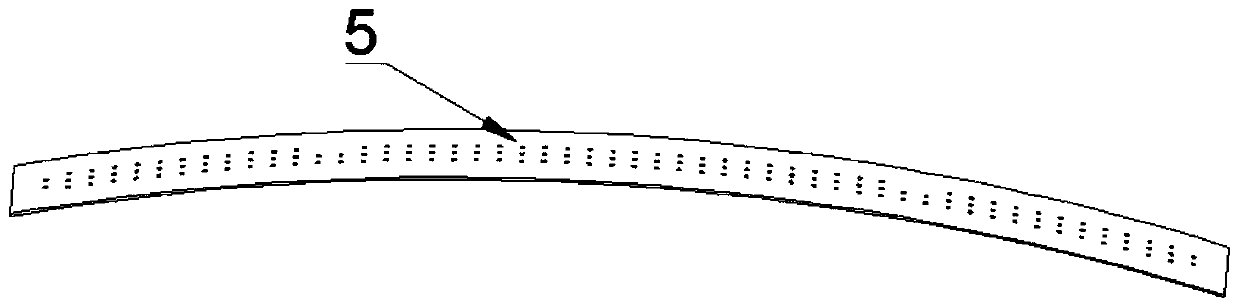

[0038] Specific implementation mode three: combination image 3 This embodiment will be described. The impact plate 5 of this embodiment is provided with several impact holes. In this way, several impingement holes on the impingement plate 5 are used to cool the inner wall of the fan-shaped turbine outer ring block 1 . Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com