Screw-free nut

A technology of nuts and internal threads of nuts, which is applied in the field of mechanical parts, can solve the problems of indetermining the size and weight of the installation screw diameter, deviation from the predetermined position, and unusable nuts, etc., to achieve the effect of improving the fastness of fixing, simple operation and quick installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

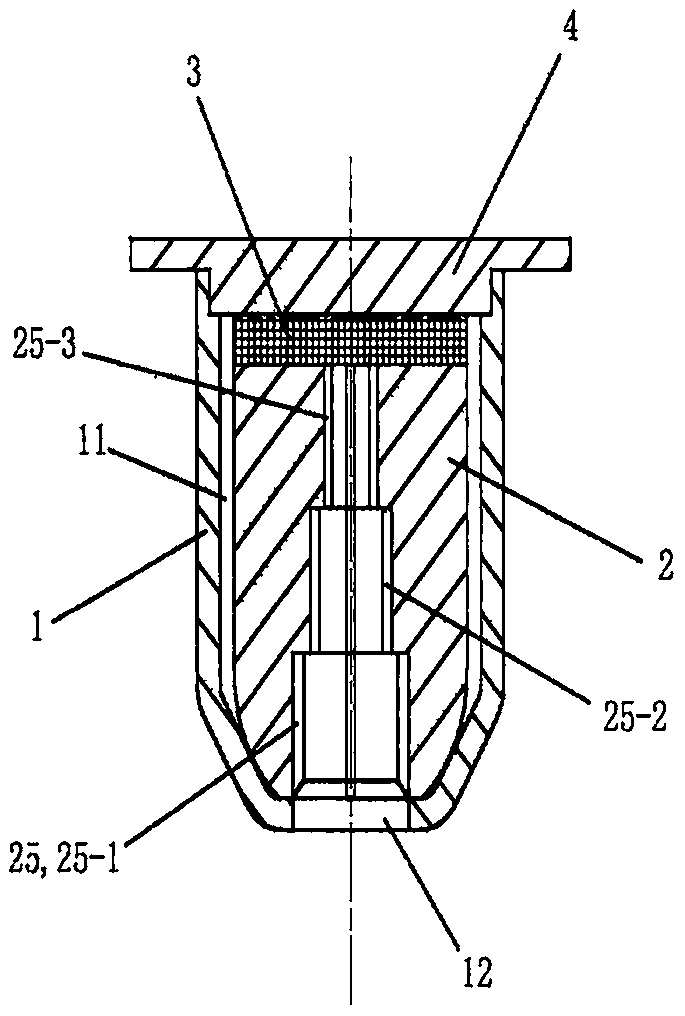

[0030] see figure 1 , The nut of this embodiment includes a seat body 1, a nut assembly 2, a rubber gasket 3, a fixed cover 4 and a positioner 5.

[0031] see figure 1 , The seat body 1 is an integral piece of steel. The base 1 is provided with a cavity 11 with an upward opening. The shape of the upper part of the cavity 11 is a cylindrical shape, and the shape of the lower part of the cavity is a truncated cone shape with a large upper part and a smaller lower part. The upper inner wall of the cavity 11 is provided with a thread, which is also an internal thread on the upper part of the seat body 1. The outer shape of the seat body 1 corresponds to the shape of the cavity 11, that is, the seat body 1 is a shell with an upward opening. The center of the lower part of the base 1 is provided with a central through hole 12 communicating with the cavity 11, and the two are arranged coaxially.

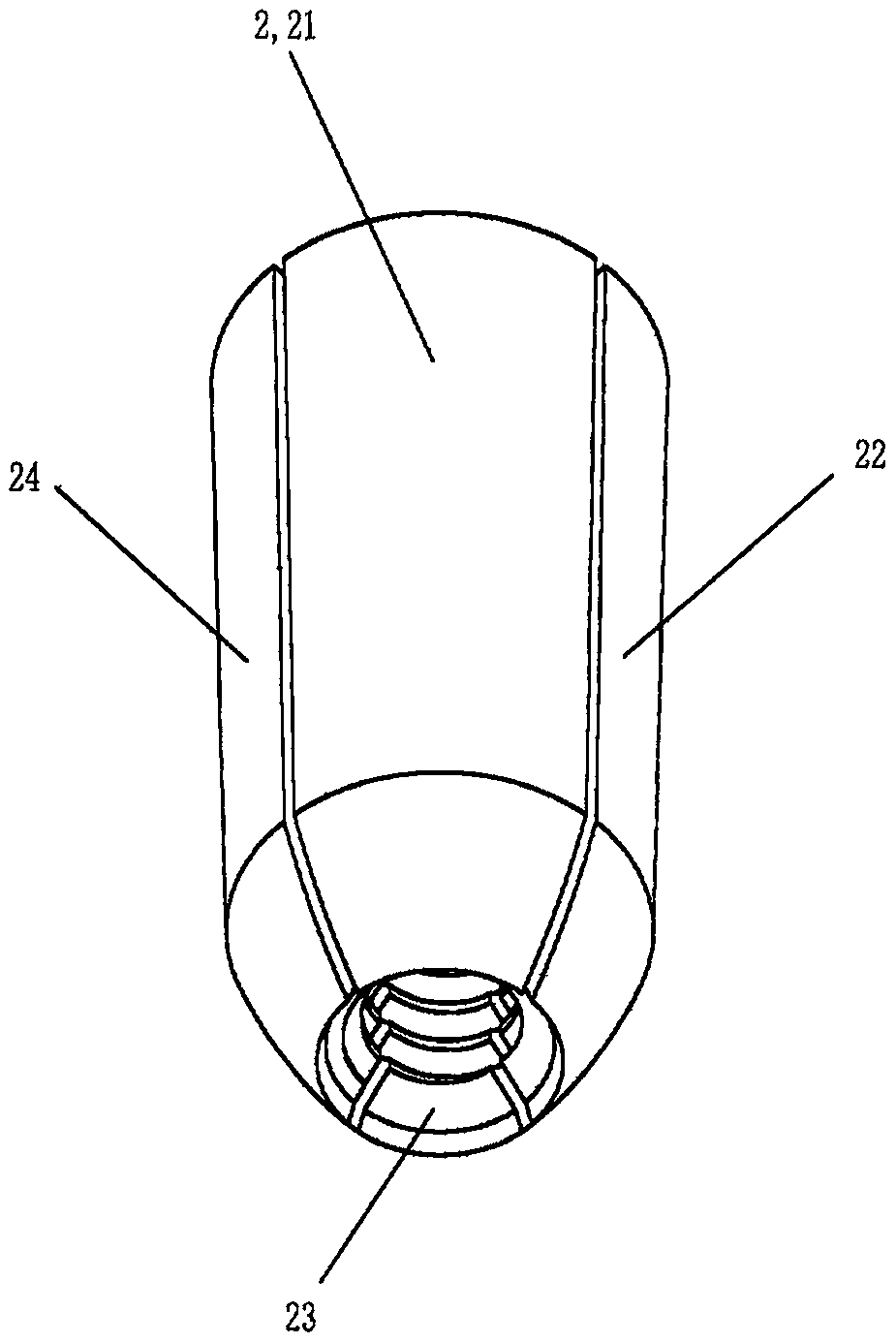

[0032] see figure 1 with figure 2 , The nut assembly 2 is composed of a first petal nut ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com