Plant LED light fill-in lamp

An LED fill light, plant technology, applied in the fields of botanical equipment and methods, electric light sources, lighting and heating equipment, etc., can solve the problems of no time-controlled switch, unable to fill light evenly, unable to time, etc., to correct natural Insufficient light, scientific and reasonable structure, safe and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

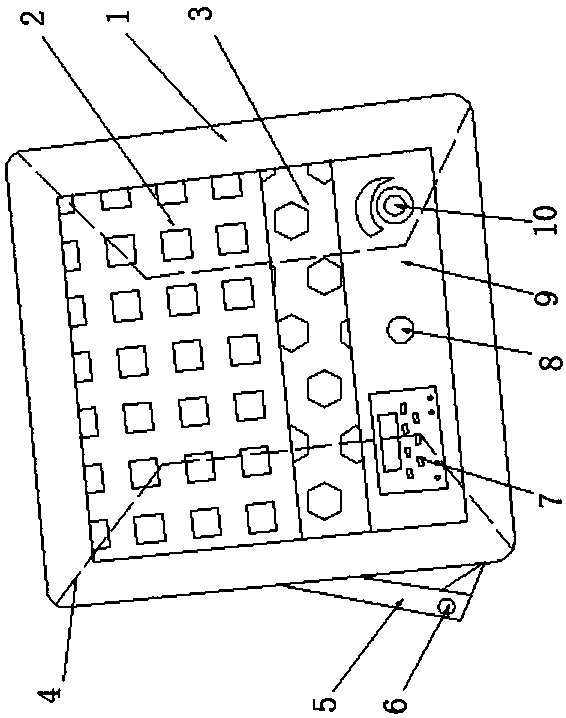

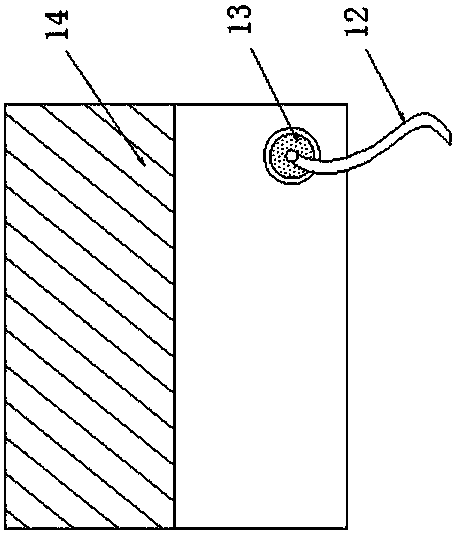

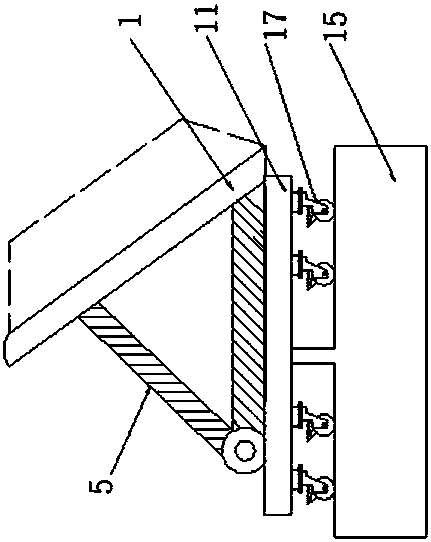

[0019] Example: such as Figure 1-4 As shown, the present invention provides a technical solution for LED supplementary light, a plant LED supplementary light, including a protective frame 1, a red LED 2, a blue LED 3, a reflector 4, a bracket 5, a rotating latch 6, a time control switch 7, Power switch 8, console 9, rotary switch 10, rotary table 11, power cord 12, wire waterproof ring 13, heat sink 14, operation box 15, rotating shaft 16, universal wheel 17, second bevel gear 18, first bevel Gear 19, motor 20 and motor bracket 21, both sides of protective frame 1 are provided with reflector 4, and the inner side of protective frame 1 is provided with red light LED...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com