Intermediate-frequency heating and stable combustion coal powder burner and use method

A pulverized coal burner and burner technology, which is applied in the direction of combustion methods, burners for burning powder fuel, burners, etc., can solve the problems that the load cannot be reduced too low, and low calorific value coal cannot be used, so as to achieve increased stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

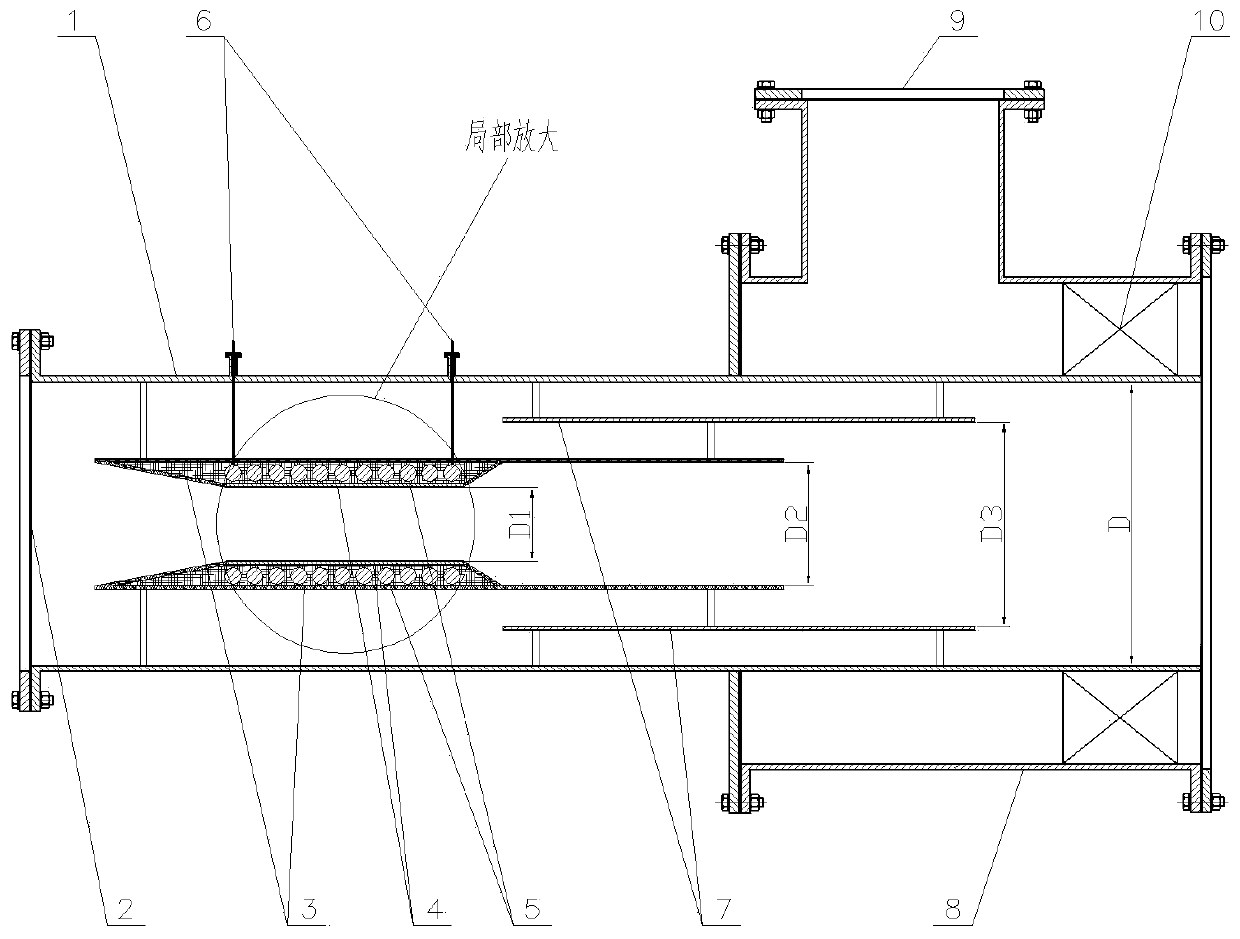

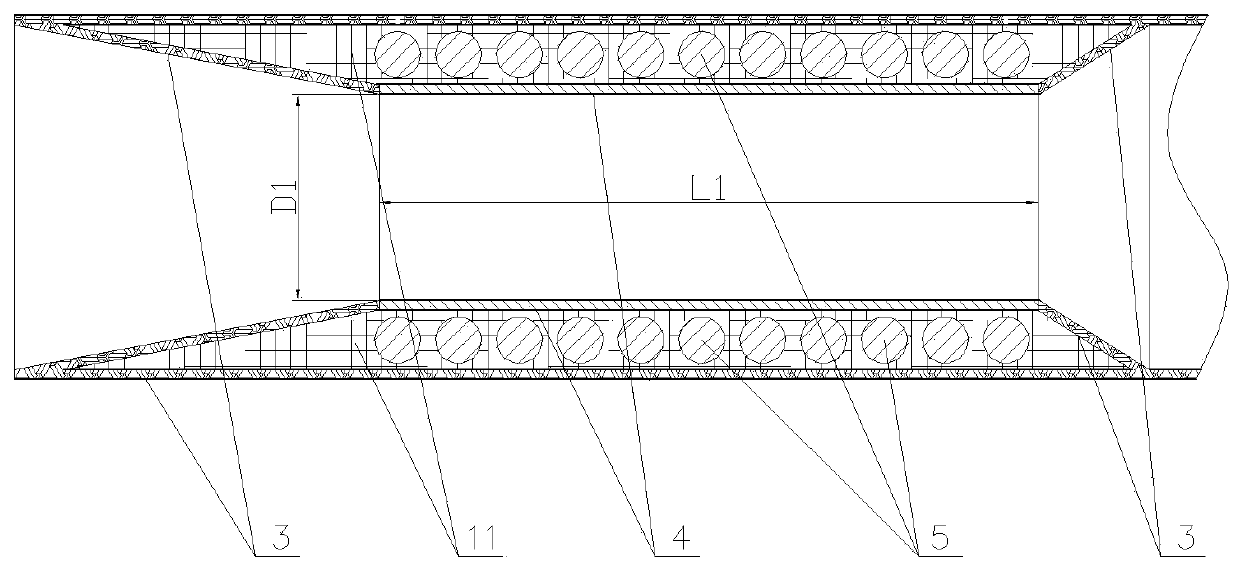

[0013] In order to achieve the above object, the present invention provides the following scheme: a medium-frequency heating stable combustion pulverized coal burner, including 1, a pulverized coal burner shell, 2, a primary air inlet, 3, a non-metallic pulverized coal partition plate, 4 . Metal pulverized coal partition, 5. Intermediate frequency heating coil, 6. Terminal post, 7. Second and third stage pulverized coal partition, 8. Secondary air box, 9. Secondary air inlet, 10. Secondary cyclone streamer.

[0014] In the middle part of the pulverized coal burner shell 1, the first-level and second-level pulverized coal separation plates and the second-level and third-level pulverized coal separation plates 7 are arranged in sequence. The pulverized coal partition plate 7 is downstream and peripheral, and divides all pulverized coal into primary pulverized coal, secondary pulverized coal and tertiary pulverized coal. The primary and secondary pulverized coal partitions inclu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com