Debris flow area directional blasting equipment and method in a mine

A technology of directional blasting and debris flow, which is applied in the field of mine blasting to achieve the effect of smooth and smooth excavation surface, small damage impact, and saving engineering investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

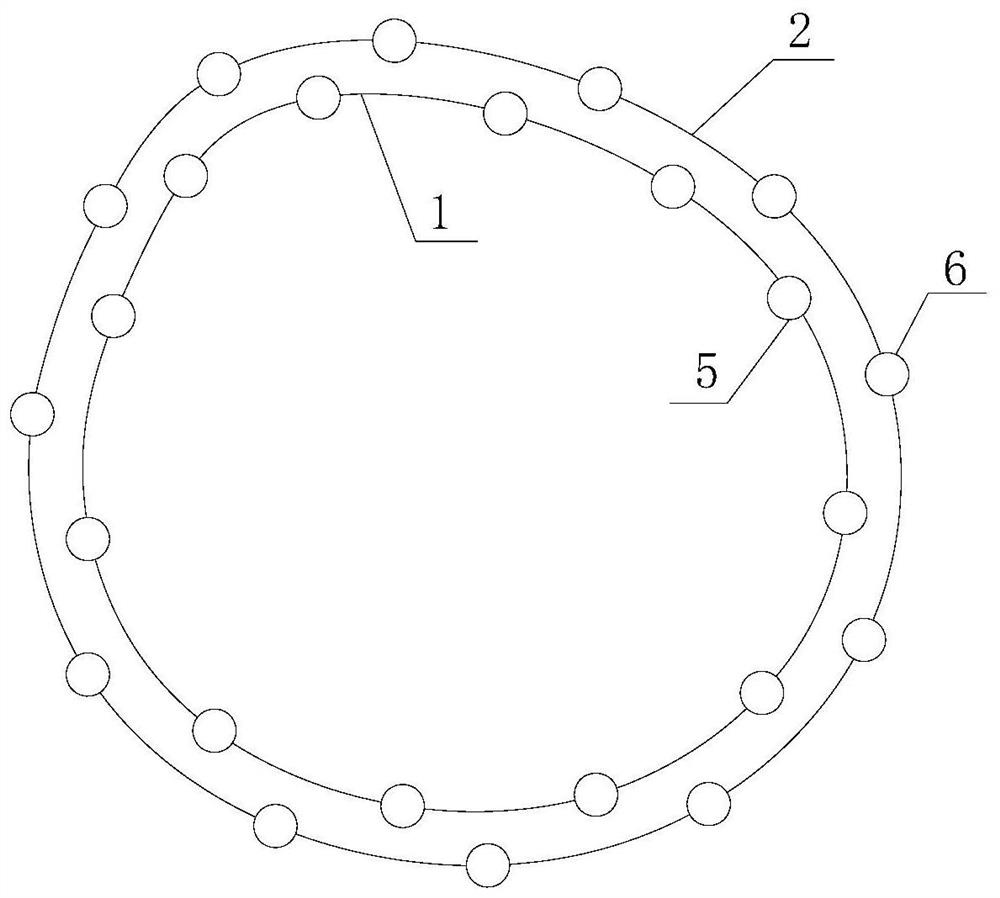

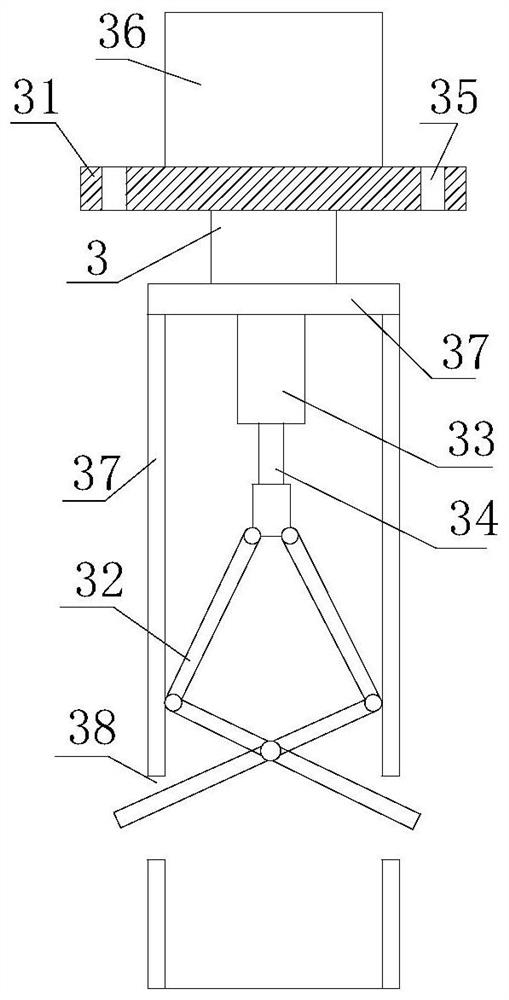

[0035] This embodiment provides a directional blasting equipment in the debris flow area of a mine, which includes a first contour line 1 and a second contour line 2 depicted on the mine, and the first contour line 1 is provided with a plurality of intervals. The first blast hole and the second blast hole are provided with a plurality of second blast holes arranged at intervals on the second contour line 2. The first blast hole is provided with a plurality of first blast slots arranged at intervals from top to bottom. There are a plurality of second blasting slots arranged at intervals from top to bottom. The drilling diameter expanding device 3 or blasting device is placed in the first blasting slot, and the drilling diameter expanding device 3 or blasting device is placed in the second blasting slot. device 4.

[0036] In the present invention, blasting is carried out in the area of the first contour line first, and then blasting in the area of the second contour line,...

Embodiment 2

[0057] The distance between the first contour line 1 and the second contour line 2 in the embodiment is set to 0.3m. The slide bar is a cylindrical structure. On the first contour line 1, the distance between two adjacent first blast holes is 0.35m. On the second contour line 2, the distance between two adjacent second blast holes is 0.7m.

[0058] In actual operation, when the distance between two adjacent first blast holes is half of the distance between two adjacent second blast holes, the blasting effect is the best.

[0059] Drilling device 3 and blasting device 4 still adopt the same structure and the same working principle as embodiment 1, specifically as follows:

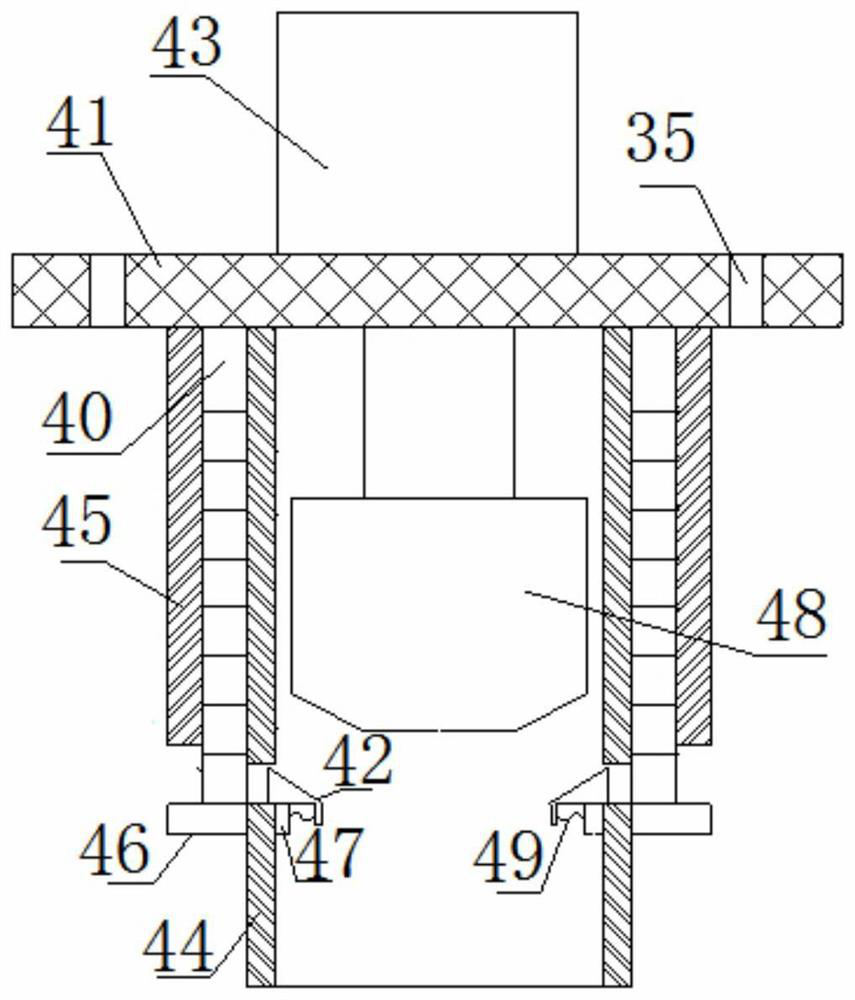

[0060] The blasting device 4 includes a fixed plate 41 and a wedge assembly 42. The upper end of the fixed plate 41 is equipped with a blasting cylinder 43 and a sling connection hole 35. The lower end of the fixed plate 41 is connected with an inner cylinder 44 and an outer cylinder 45. The inner cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com