A rock drilling jumbo and a tunnel excavation method for reducing surrounding rock disturbance

A technology of rock drilling rig and tunneling method, which is applied in tunnels, percussion drilling, drilling equipment and methods, etc. The effect of rock stability, reduction of vibration and noise, and increased drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

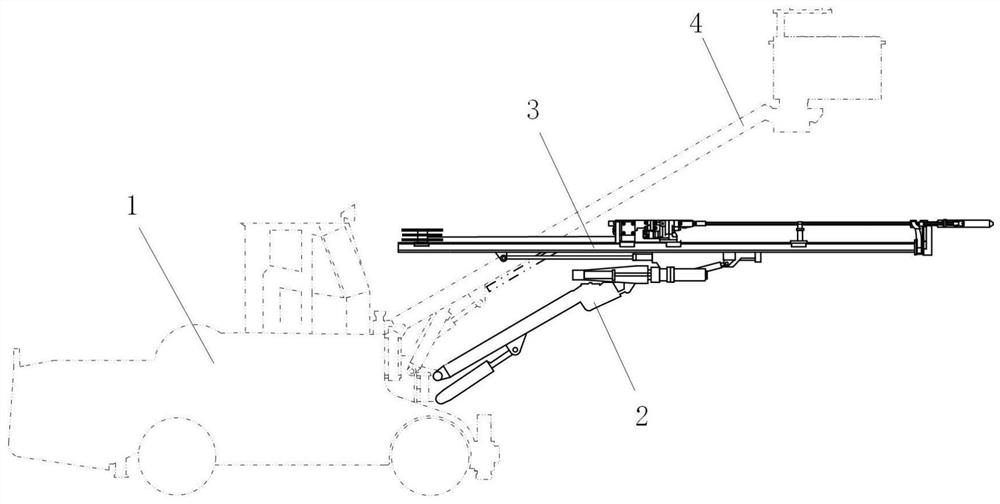

[0045] see Figure 1 to Figure 8, a rock drilling jumbo, comprising a car body 1 and a chassis that drives the car body to move, a boom system 2 placed at the front end of the car body for adjusting the rock drilling position, a drilling system 3 arranged on the boom system, which can The operation platform system 4 installed in a complete set, and the execution end control system that can control the angle and depth of drilling system rock drilling. Wherein the boom system 2 is installed on the front part of the vehicle body 1 and can swing vertically and horizontally. The drilling system 3 is installed at the end of the boom system 2, and can rotate and axially deflect at a certain angle around the end of the boom. The working platform system 4 is installed on the front end of the trolley body 1 in the same manner as the boom system 2 .

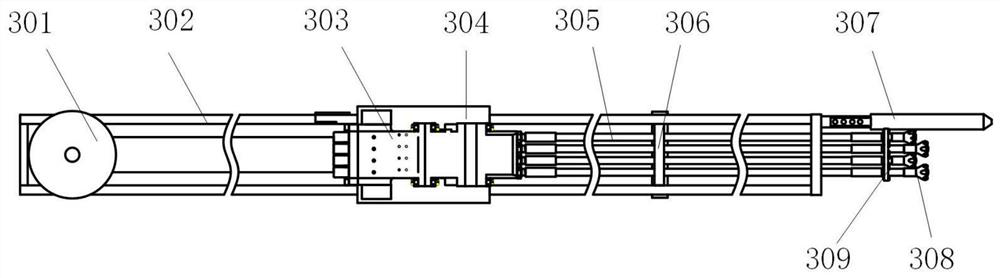

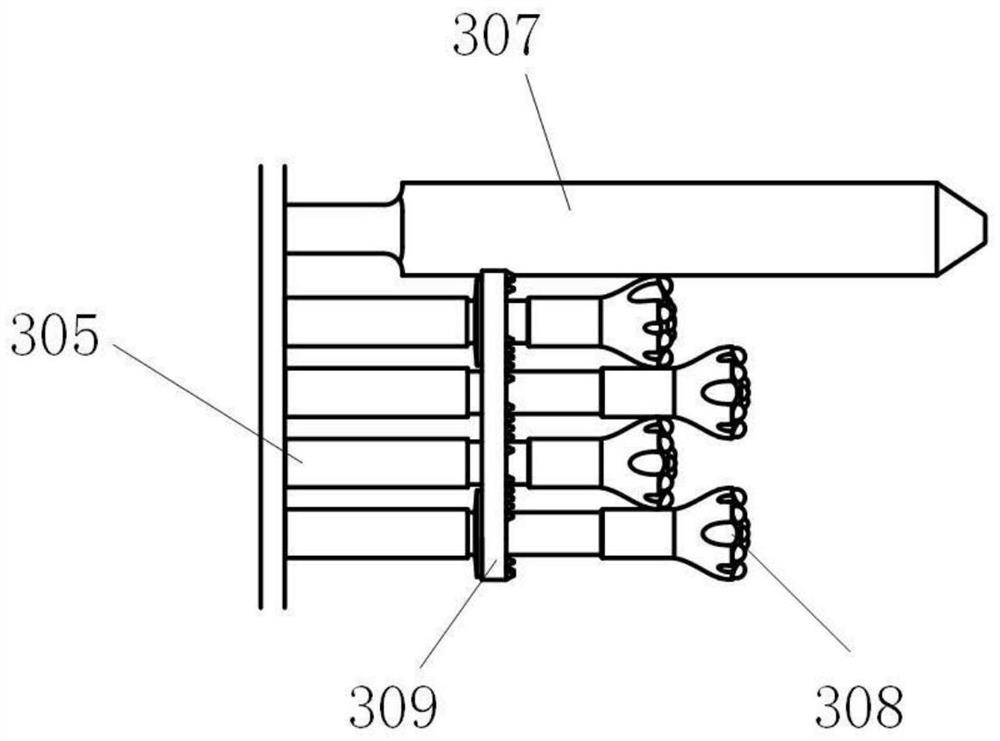

[0046] Such as figure 2 As shown, the drilling system 3 includes a reel 301, a propulsion beam 302, a row of drills 303, a sliding bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com