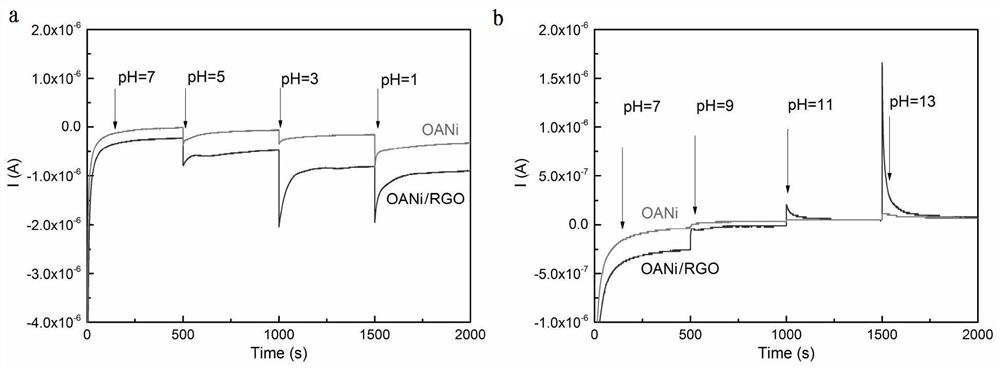

pH electrochemical sensor based on aniline oligomer/graphene composite and its preparation method

An aniline oligomer and composite material technology, applied in the direction of material electrochemical variables, etc., can solve the problems of complex preparation of polyaniline, difficult application and promotion, and high processing difficulty, achieving excellent solubility and processing performance, improving pH response sensitivity, The effect of improved detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

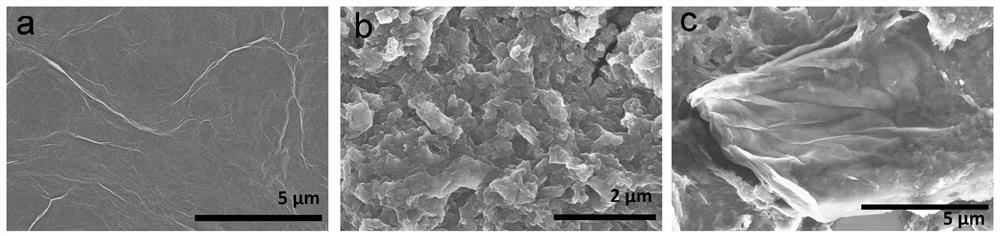

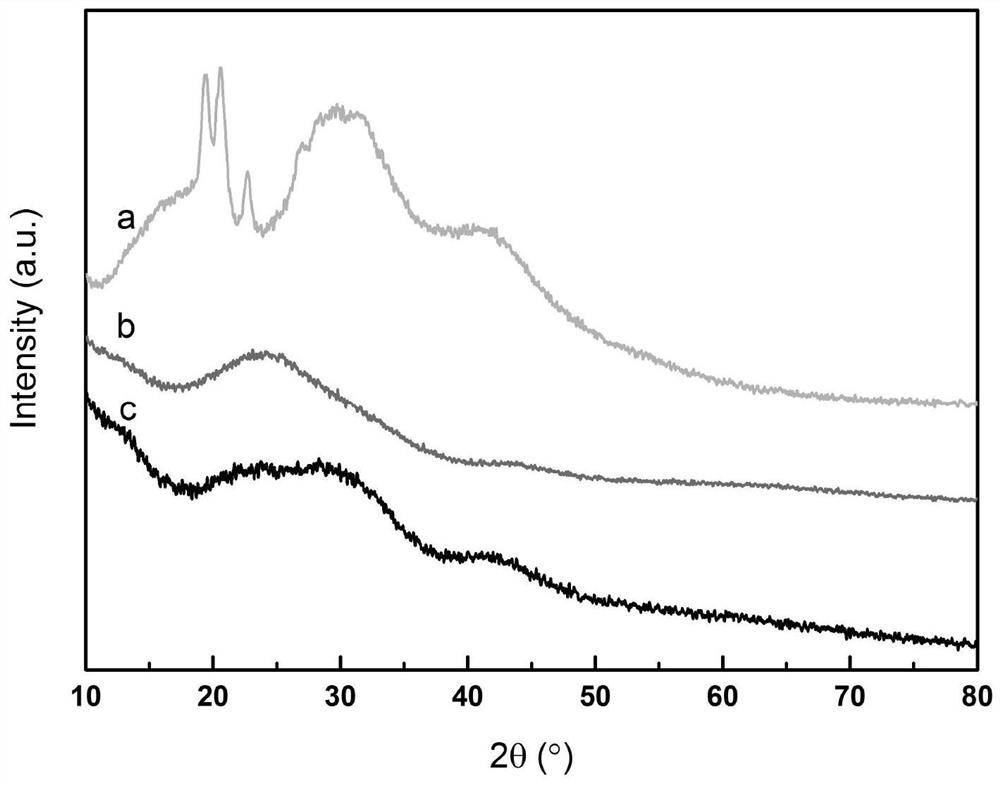

[0030] Step 1, 20 mg of aniline tetramer is dissolved in 20 mL of ethanol, and magnetic stirring is used to prepare aniline tetramer solution;

[0031] Step 2, adding 20mL concentration of graphene dispersion of 1mg / mL to the aniline tetramer solution prepared in step 1, magnetically stirring for 12 hours after ultrasonication for 20min, and fully mixing to obtain a composite material dispersion;

[0032] Step 3. Take 10 μL of the composite material dispersion prepared in Step 2 and drop it on the polished and cleaned ITO conductive glass surface, and dry it naturally in a fume hood.

Embodiment 2

[0034] Step 1, 0.2 mg of aniline tetramer was dissolved in 20 mL of ethanol, and magnetic stirring was used to prepare aniline tetramer solution;

[0035] Step 2, adding 20mL concentration of graphene dispersion of 1mg / mL to the aniline tetramer solution prepared in step 1, magnetically stirring for 12 hours after ultrasonication for 20min, and fully mixing to obtain a composite material dispersion;

[0036] Step 3. Take 10 μL of the composite material dispersion prepared in Step 2 and drop it on the polished and cleaned ITO conductive glass surface, and dry it naturally in a fume hood.

Embodiment 3

[0038] Step 1, dissolving 200mg of aniline tetramer in 20mL of ethanol, and using magnetic stirring to obtain aniline tetramer solution;

[0039] Step 2, adding 20mL concentration of graphene dispersion of 1mg / mL to the aniline tetramer solution prepared in step 1, magnetically stirring for 12 hours after ultrasonication for 20min, and fully mixing to obtain a composite material dispersion;

[0040] Step 3. Take 10 μL of the composite material dispersion prepared in Step 2 and drop it on the polished and cleaned ITO conductive glass surface, and dry it naturally in a fume hood.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com