Fertilizer slow-release material with soil improving function as well as preparation method and application thereof

A fertilizer slow-release and soil improvement technology, which is applied in the fields of application, ammonium salt fertilizer, fertilizer mixture, etc., can solve the problem of low added value of natural silicate minerals, weak nutrient adsorption and exchange capacity of fertilizers, poor slow-release effect of fertilizers, etc. problems, to achieve excellent water and fertilizer retention effects, improve soil water retention energy, and promote the formation of soil aggregates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

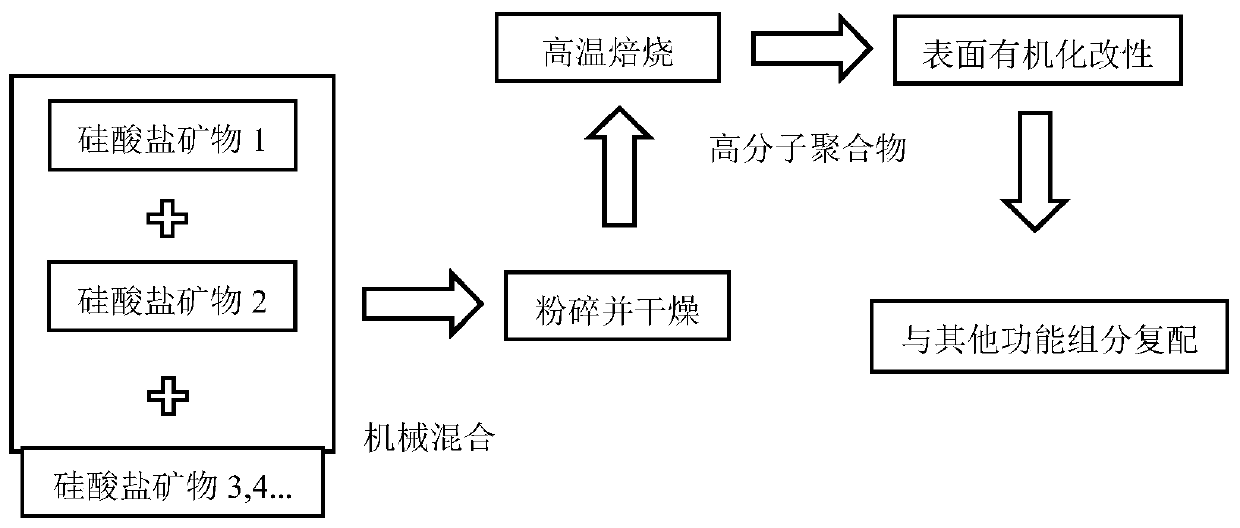

[0042] The fertilizer slow-release material with the function of improving soil, the preparation method is as follows:

[0043] S1. Mix montmorillonite, zeolite, attapulgite and sepiolite in a mass ratio of 5:60:30:5 to obtain natural silicate mineral material, crush to 100 mesh and dry to make the water content below 2% , and then calcined at 480°C for 1.5h to obtain natural silicate mineral materials that have been crushed, dried and calcined;

[0044] S2. Dissolve 0.25 parts by weight of anionic polyacrylamide and 0.1 parts by weight of potassium polyacrylate in 10 parts by weight of water to obtain a polymer modified layer solution, and uniformly spray the polymer modified layer solution on 100 parts by weight of the process Crushing, drying and calcining the surface of the natural silicate mineral material, and then treating it at 125°C for 1 hour, carrying out surface organic modification, drying, and crushing to 100 meshes.

[0045] Among them, the degree of hydrolysis...

Embodiment 2

[0047] The fertilizer slow-release material with the function of improving soil, the preparation method is as follows:

[0048] S1. Mix zeolite and attapulgite at a mass ratio of 70:30 to obtain a natural silicate mineral material, crush it to 200 mesh and dry it so that the water content is below 2%, and then roast it at 550°C for 1.5h to obtain a Crushed, dried and calcined natural silicate mineral materials;

[0049] S2. Dissolve 0.2 parts by weight of anionic polyacrylamide and 0.15 parts by weight of potassium polyacrylate in 10 parts by weight of water to obtain a polymer modified layer solution, and uniformly spray the polymer modified layer solution on 100 parts by weight of the process The surface of the natural silicate mineral material treated by crushing, drying, and roasting is treated at 120°C for 1.5 hours, dried, and crushed to 200 meshes.

[0050] Wherein, the degree of hydrolysis of the anionic polyacrylamide is 95%, and the molecular weight is 22 million. P...

Embodiment 3

[0052] The fertilizer slow-release material with the function of improving soil, the preparation method is as follows:

[0053] S1. Mix montmorillonite, attapulgite, sepiolite, and zeolite in a mass ratio of 30:3:60:7 to obtain a natural silicate mineral material, crush it to 100 mesh and dry it so that the water content is less than 2% , and then calcined at 500°C for 1.5 hours to obtain natural silicate mineral materials that have been crushed, dried and calcined;

[0054] S2. Dissolve 0.3 parts by weight of anionic polyacrylamide and 0.2 parts by weight of potassium polyacrylate in 10 parts by weight of water to obtain a polymer modified layer solution, and uniformly spray the polymer modified layer solution on 100 parts by weight of the process Crushing, drying, and calcining the surface of natural silicate mineral materials, then treating at 130°C for 2 hours, drying, and crushing to 100 meshes.

[0055] Among them, the degree of hydrolysis of anionic polyacrylamide is 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com