Vessel pressurization explosion simulation system

An explosion simulation and container technology, which is applied in the direction of material inspection products, fuel oil testing, etc., can solve the problem of inability to detect the lethality of fragments, and achieve the effect of saving testing costs and avoiding explosions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

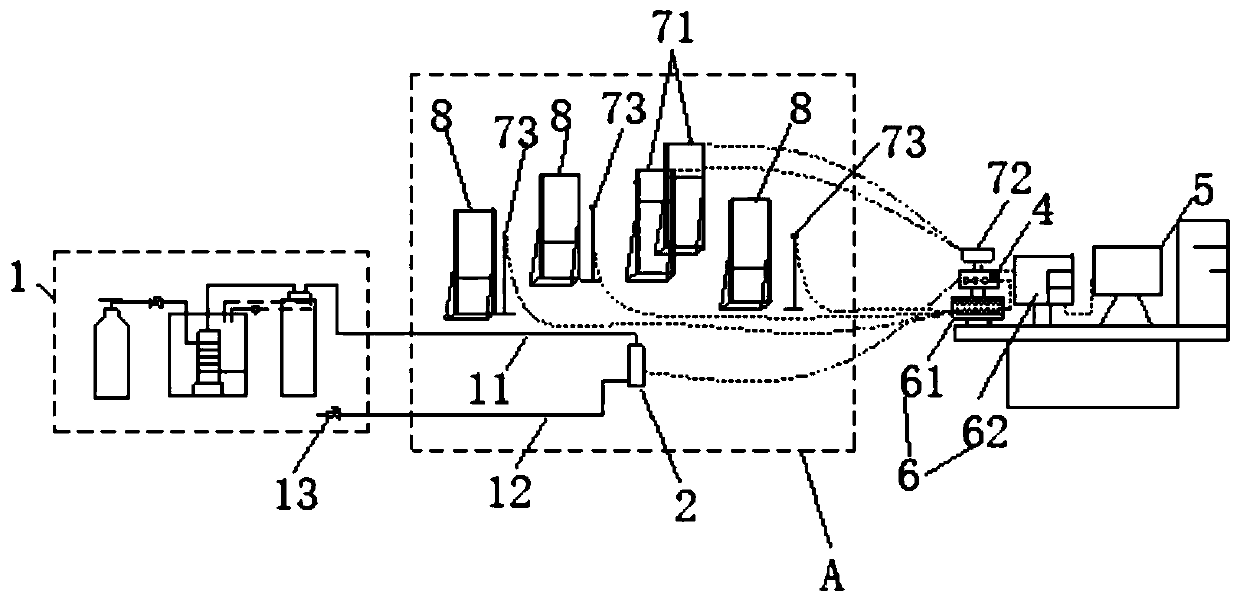

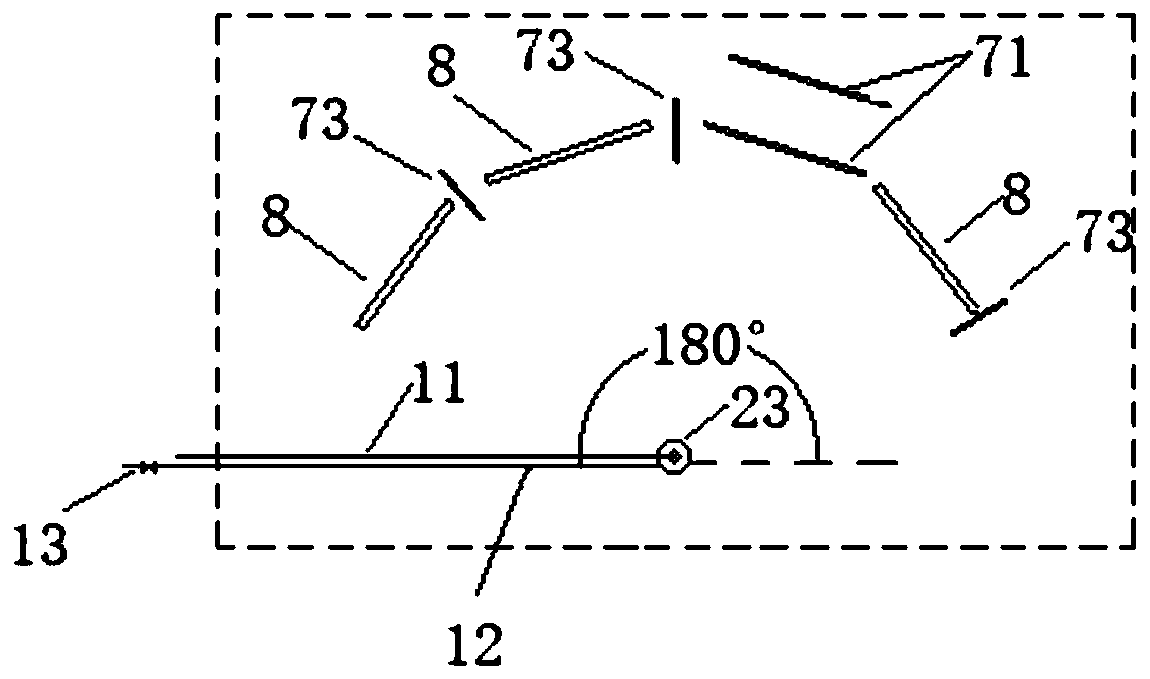

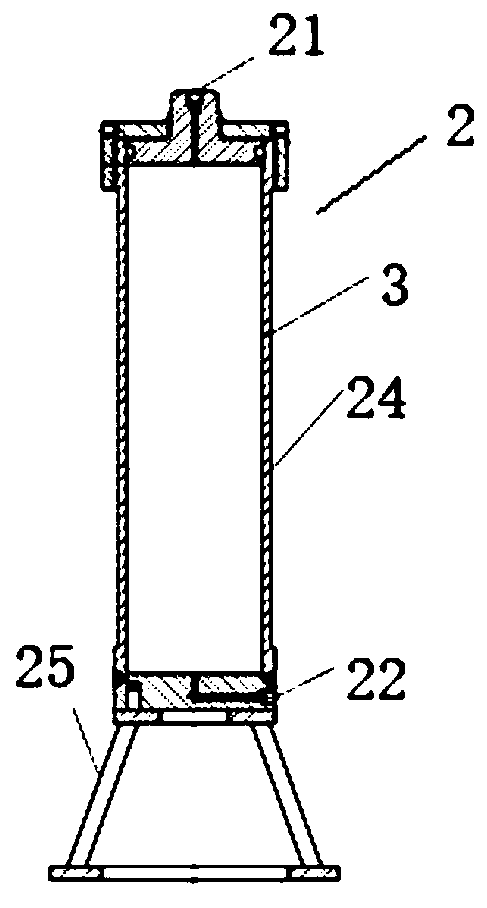

[0041] Such as figure 1 As shown, the embodiment of the present invention describes a container pressurization explosion simulation system, especially a container pressurization explosion simulation system under the condition of dense obstacles, which includes a pressure container 2, a pressurization device 1, and a flying component 3 and monitoring devices. Among them such as figure 1 As shown in -3, the pressure container 2 includes a gas injection port 21 and an exhaust port 22, the gas injection port 21 is connected to the pressurization device 1 through the input pipe 11, and the exhaust port 22 is connected to the outside through the output pipe 12, wherein the output pipe 12 is A valve 13 is provided to control its on-off. The pressurization device 1 inputs the pressurized medium to the pressure container 2 through the gas injection port 21, wherein the pressurized medium in this embodiment is carbon dioxide gas; Scatter when impacted; the monitoring device includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com