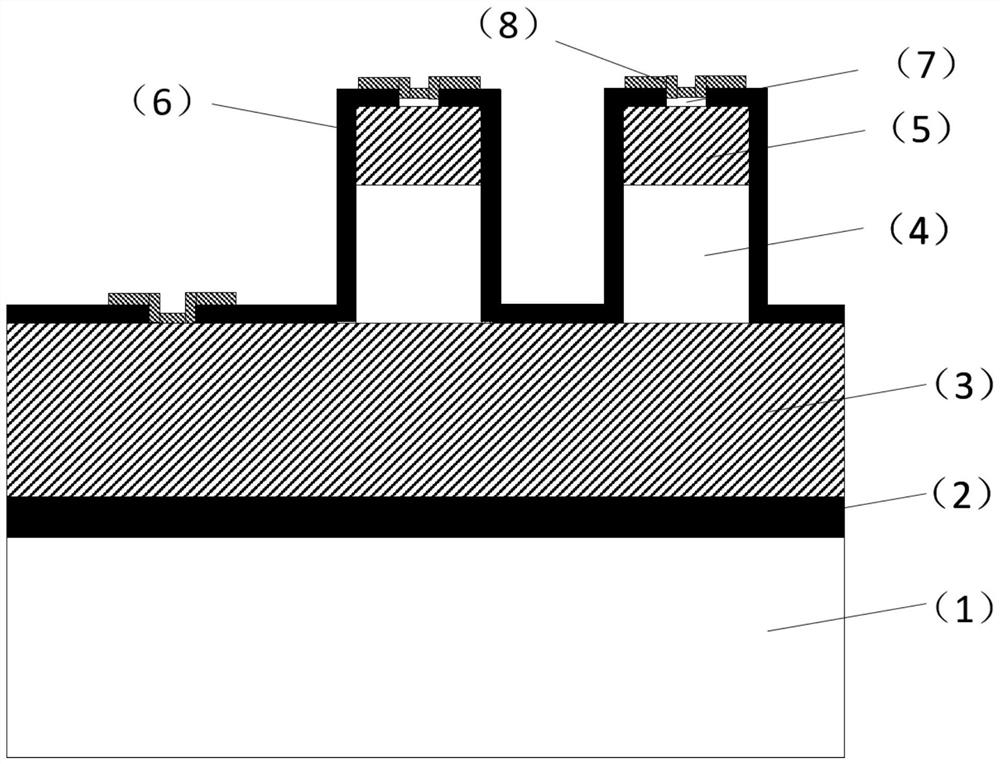

A low stress passivated mesa-type extended wavelength indium gallium arsenide detector preparation method

A detector and table-top technology, which is applied in the field of infrared detector preparation, can solve the problems of large warpage of large area array detector chips, poor reliability of large area array detector chips, unfavorable short-wave infrared focal plane connectivity rate and the like. , to achieve good passivation effect, reduce dangling keys, and achieve the effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

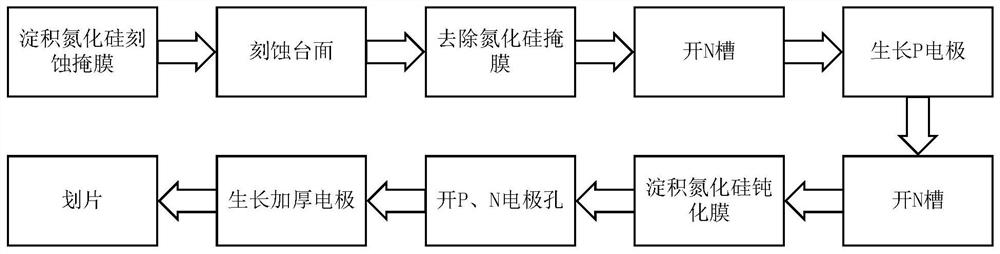

[0047] 1 Deposit silicon nitride etching mask, used as an etching mask, using plasma enhanced chemical vapor deposition (PECVD) technology to deposit silicon nitride with a thickness of 400±20nm, RF power of 40±5W, substrate Bottom temperature 330±5℃, gas flow SiH 4 :N 2is 1:18;

[0048] 2 Etching the mesa is divided into two parts: etching silicon nitride and etching InGaAs epitaxial material to form the mesa. Silicon nitride is etched using inductively coupled plasma (ICP) etching technology. The etching conditions are: ICP power is 2000±5W, RF power is 40±5W, and SF is used. 6 As an etching gas; use inductively coupled plasma (ICP) etching technology to etch the mesa, the etching conditions are: ICP power is 350±5W, RF power is 130±5W, using Cl 2 and N 2 as an etching gas;

[0049] 3 Remove the silicon nitride mask, use hydrofluoric acid buffer solution to etch at room temperature for 120±5s, and the volume ratio of the etching solution is HF:NH 4 F:H 2 O is 3:6:10; ...

Embodiment 2

[0058] 1 Deposit silicon nitride etching mask, used as an etching mask, using plasma enhanced chemical vapor deposition (PECVD) technology to deposit silicon nitride with a thickness of 400±20nm, RF power of 40±5W, substrate Bottom temperature 330±5℃, gas flow SiH 4 :N 2 is 1:18;

[0059] 2 Etching the mesa is divided into two parts: etching silicon nitride and etching InGaAs epitaxial material to form the mesa. Silicon nitride is etched using inductively coupled plasma (ICP) etching technology. The etching conditions are: ICP power is 2000±5W, RF power is 40±5W, and SF is used. 6 As an etching gas; use inductively coupled plasma (ICP) etching technology to etch the mesa, the etching conditions are: ICP power is 350±5W, RF power is 130±5W, using Cl 2 and N 2 as an etching gas;

[0060] 3 Remove the silicon nitride mask, use hydrofluoric acid buffer solution to etch at room temperature for 120±5s, and the volume ratio of the etching solution is HF:NH 4 F:H 2 O is 3:6:10;...

Embodiment 3

[0069] 1 Deposit silicon nitride etching mask, used as an etching mask, using plasma enhanced chemical vapor deposition (PECVD) technology to deposit silicon nitride with a thickness of 400±20nm, RF power of 40±5W, substrate Bottom temperature 330±5℃, gas flow SiH 4 :N 2 is 1:18;

[0070] 2 Etching the mesa is divided into two parts: etching silicon nitride and etching InGaAs epitaxial material to form the mesa. Silicon nitride is etched using inductively coupled plasma (ICP) etching technology. The etching conditions are: ICP power is 2000±5W, RF power is 40±5W, and SF is used. 6 As an etching gas; use inductively coupled plasma (ICP) etching technology to etch the mesa, the etching conditions are: ICP power is 350±5W, RF power is 130±5W, using Cl 2 and N 2 as an etching gas;

[0071] 3 Remove the silicon nitride mask, use hydrofluoric acid buffer solution to etch at room temperature for 120±5s, and the volume ratio of the etching solution is HF:NH 4 F:H 2 O is 3:6:10;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com