Ventilation cooling structure of fully-enclosed permanent-magnet motor

A permanent magnet motor, ventilation and cooling technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems affecting the operation reliability of permanent magnet rotors, motor temperature rise, rotor structure damage, etc., and achieve a lightweight design. , The effect of strengthening heat dissipation and reducing the weight of the base

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to further explain the technical means and functions adopted by the present invention to achieve the intended invention purpose, the specific implementation, structure, features and functions of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

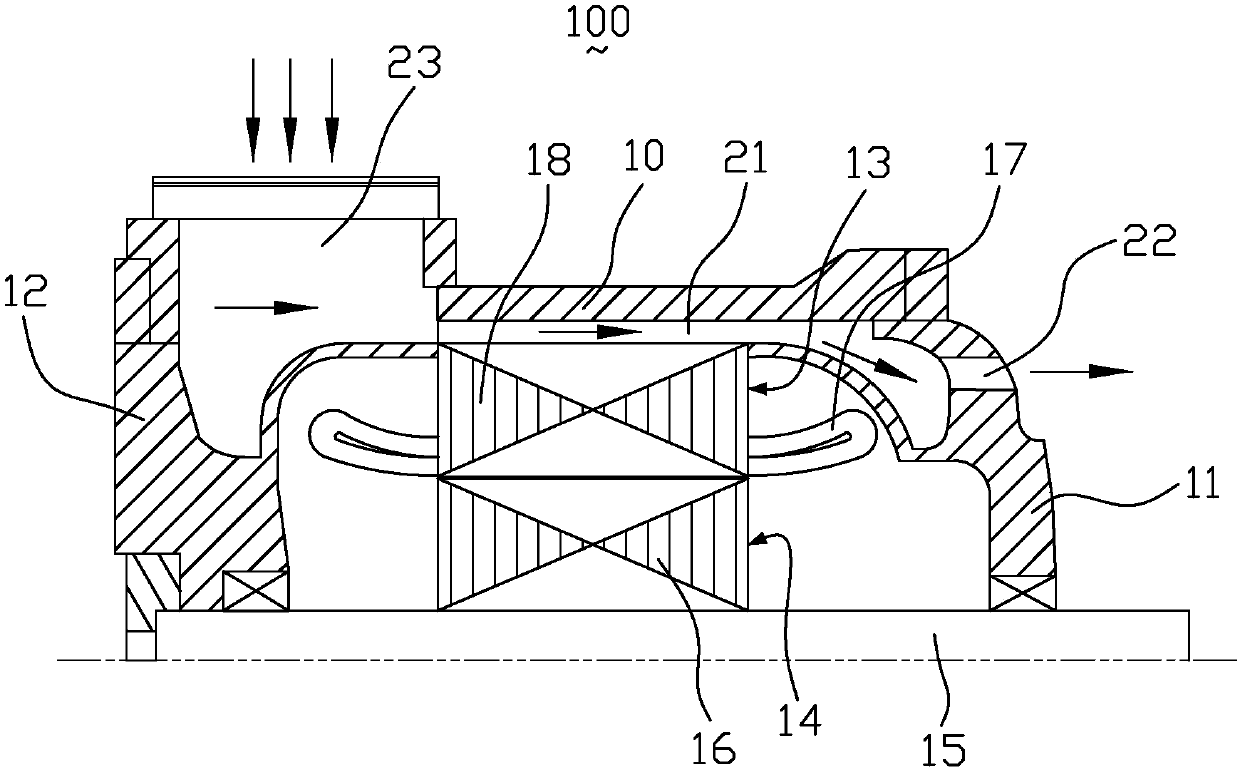

[0017] figure 1 It is a structural schematic diagram of the ventilation and cooling structure of the fully enclosed permanent magnet motor of the present invention. like figure 1 As shown, a fully enclosed permanent magnet motor ventilation cooling structure 100 includes a casing 10 , a front end cover 11 , a rear end cover 12 , a stator structure 13 , a rotor structure 14 and a pull plate 20 .

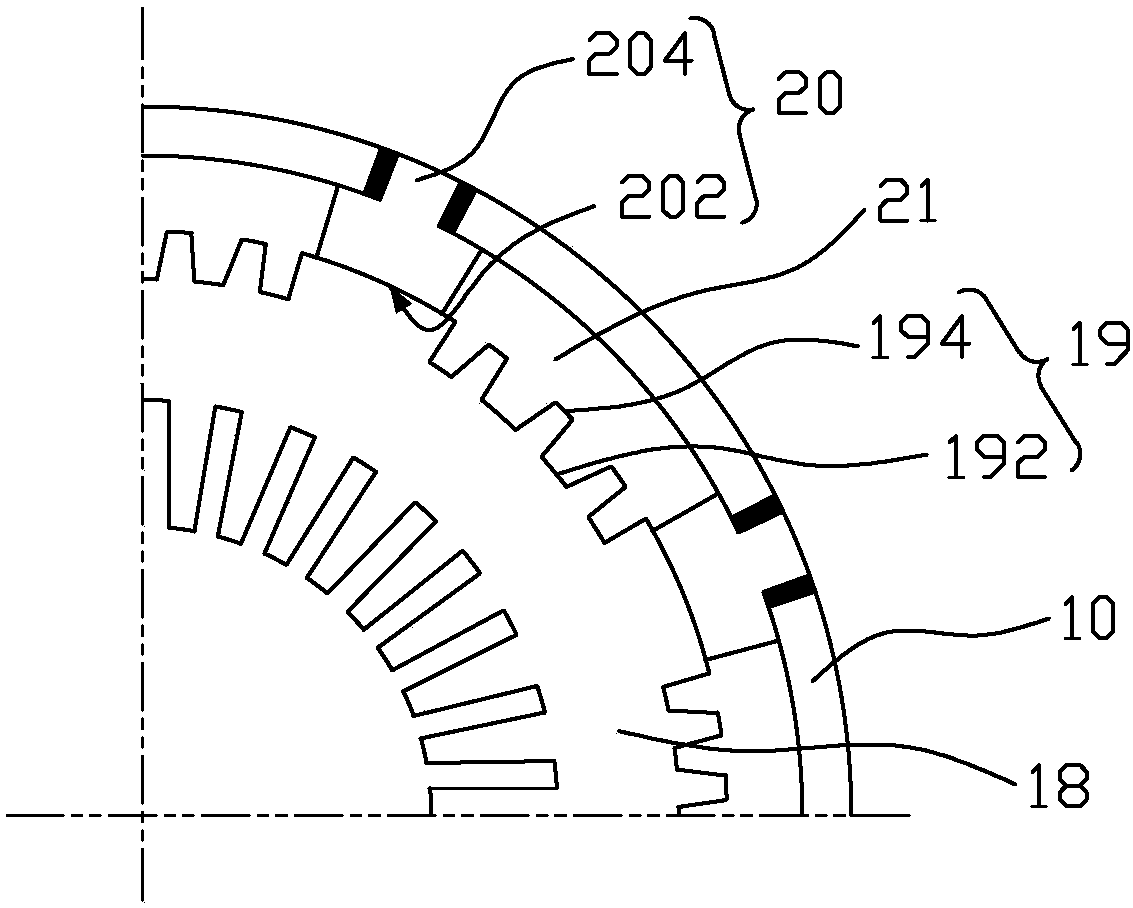

[0018] Wherein, the rotor structure 14 includes a rotating shaft 15 and a rotor core 16 , the rotor core 16 is fixedly assembled in the middle of the outer surface of the rotating shaft 15 , and the rotor core 16 is a cylindrical laminated core wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com