A kind of oridonin sustained-release tablet and preparation method thereof

A technology of oridonin and sustained-release tablets, which is applied in the direction of pharmaceutical formulas, medical preparations with no active ingredients, medical preparations containing active ingredients, etc., can solve the problem of affecting the anti-cancer effect of oridonin Difficult to reach the therapeutic concentration, low bioavailability and other problems, to achieve the effects of prolonging the drug action time, optimizing particle fluidity and anti-caking, and improving the sustained-release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

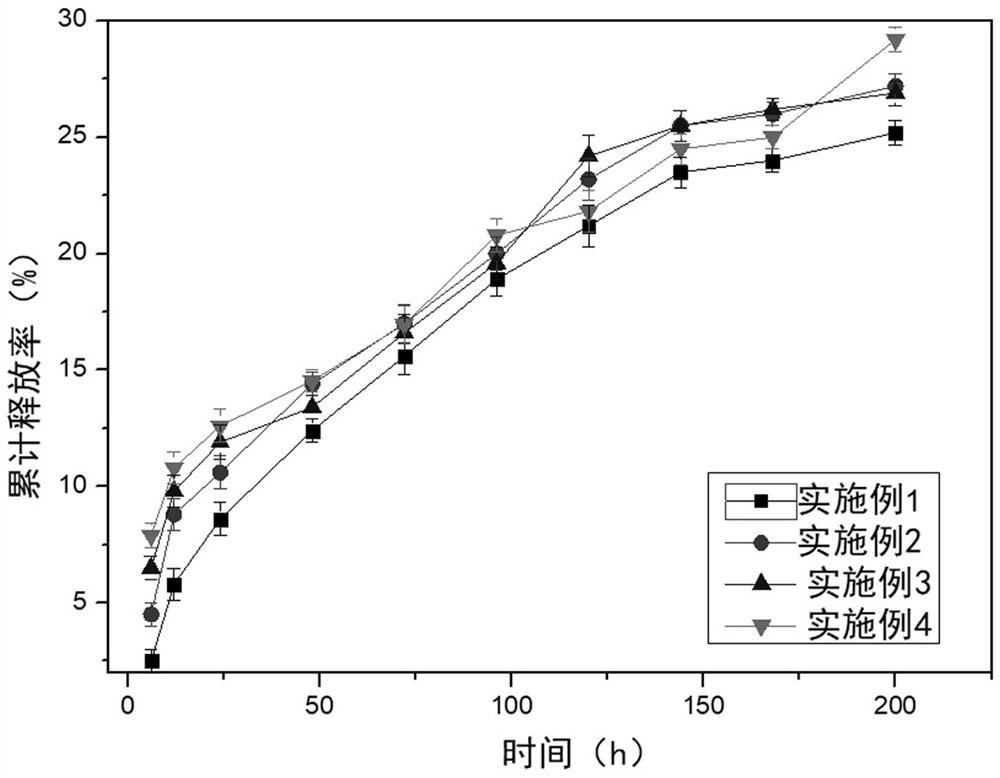

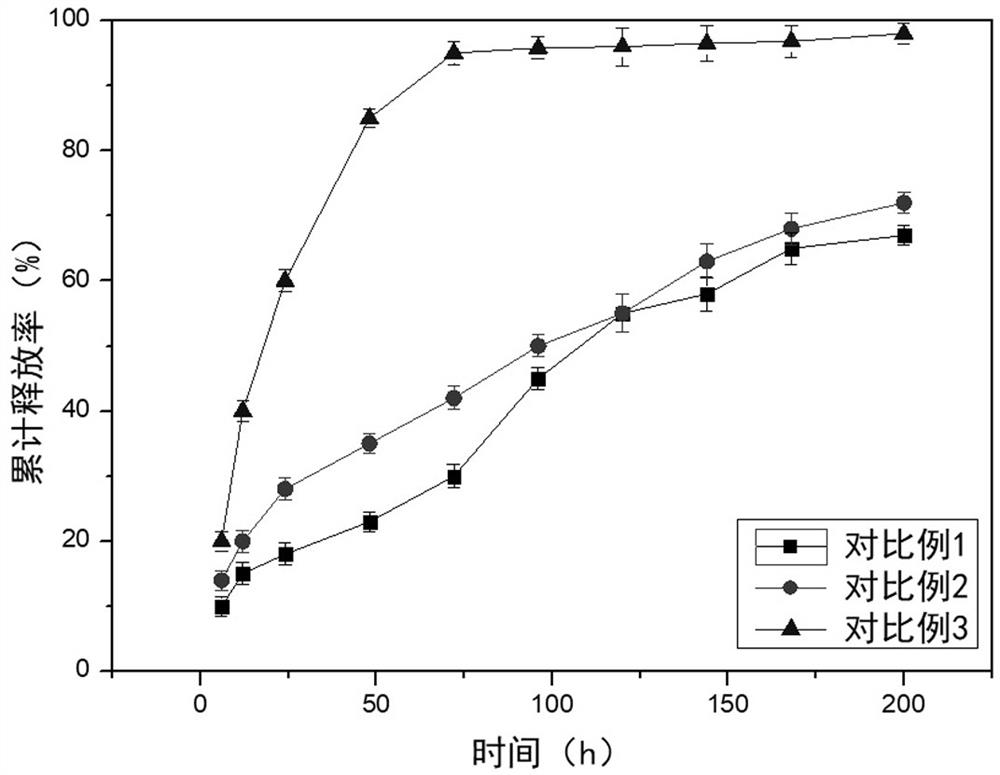

Examples

Embodiment 1

[0036] A sustained-release tablet of oridonin, consisting of the following components in weight percentage: 0.3% oridonin, 30% diacylglycerol, 40% soybean lecithin, 7% chitosan, 15% ethanol, viscose Mixture 2%, low-substituted hydroxypropyl cellulose 2%, magnesium stearate 3%, sorbitol 0.7%.

[0037] The binder is formed by mixing methylcellulose and ethylcellulose in a weight ratio of 1:1-3.

[0038] This embodiment provides a preparation method of Oridonin Sustained-release Tablets, comprising the following steps:

[0039] S1. Mix the Rubescensin A in the weight percentage with phospholipids and diacylglycerol evenly, then add ethanol and mix to obtain a Rubescensin A solution;

[0040] S2, adding chitosan and adhesive to the oridonin A solution, mixing under stirring conditions, the stirring rate is 600rpm, and the stirring time is 40min, so that the above raw materials are mixed evenly;

[0041] S3. Perform high-pressure homogenization of the oridonin A cubic liquid crys...

Embodiment 2

[0046] A sustained release tablet of oridonin, consisting of the following components in weight percentage: 0.1% oridonin, 20% diacylglycerol, 50% soybean lecithin, 5% chitosan, 10% ethanol, viscose Mixture 5%, low-substituted hydroxypropyl cellulose 5%, magnesium stearate 4%, sorbitol 0.9%.

[0047] The binder is formed by mixing methylcellulose and ethylcellulose in a weight ratio of 1:1.

[0048] This embodiment provides a preparation method of Oridonin Sustained-release Tablets, comprising the following steps:

[0049] S1. Mix the Rubescensin A in the weight percentage with phospholipids and diacylglycerol evenly, then add ethanol and mix to obtain a Rubescensin A solution;

[0050] S2, adding chitosan and adhesive to the oridonin A solution, and mixing under stirring conditions, the stirring rate is 500rpm, and the stirring time is 1h, so that the above raw materials are mixed evenly;

[0051] S3. The oridonin A cubic liquid crystal coarse dispersion solution is subject...

Embodiment 3

[0056] A sustained-release tablet of oridonin, consisting of the following components by weight percentage: 0.5% oridonin, 40% diacylglycerol, 30% soybean lecithin, 10% chitosan, 5% ethanol, viscose Mixture 4%, low-substituted hydroxypropyl cellulose 5%, magnesium stearate 5%, sorbitol 0.5%.

[0057] This embodiment provides a preparation method of Oridonin Sustained-release Tablets, comprising the following steps:

[0058] S1. Mix the Rubescensin A in the weight percentage with phospholipids and diacylglycerol evenly, then add ethanol and mix to obtain a Rubescensin A solution;

[0059] S2. Add the oridonin A solution to chitosan and binder, and mix under stirring conditions, the stirring rate is 800rpm, and the stirring time is 0.5h, so that the above raw materials are mixed evenly;

[0060] S3. Perform high-pressure homogenization of the oridonin A cubic liquid crystal coarse dispersion solution, the homogenization pressure is 2000 bar, and the homogenization times are 3 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com