Pipeline cleaning robot

A technology for cleaning robots and pipes, which is applied in the direction of cleaning hollow objects, cleaning methods and appliances, chemical instruments and methods, etc. It can solve the problems of using a large amount of cleaning liquid, insufficient cleaning power, and damage to pipes, etc., to achieve efficient cleaning and stable walking. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

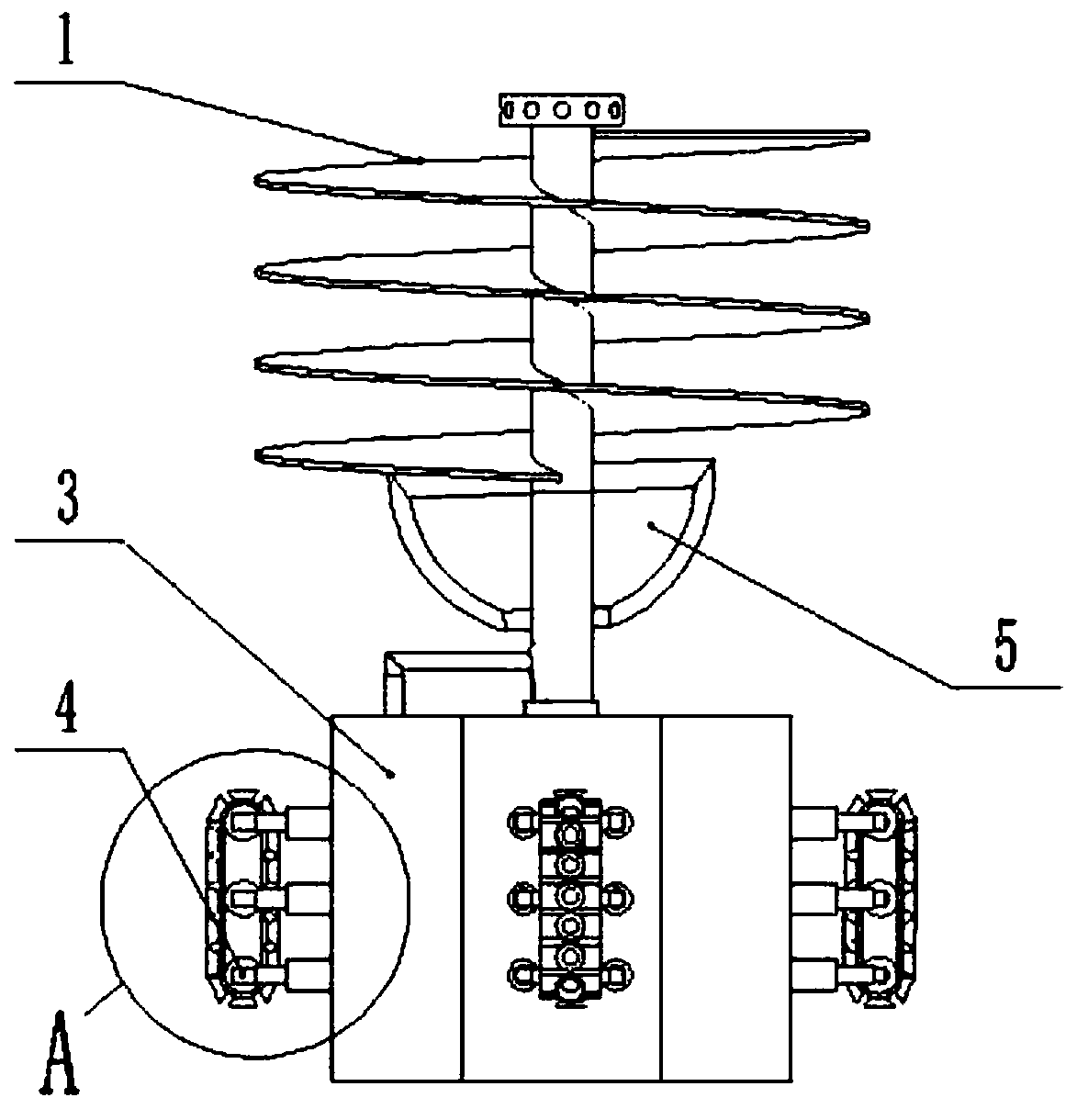

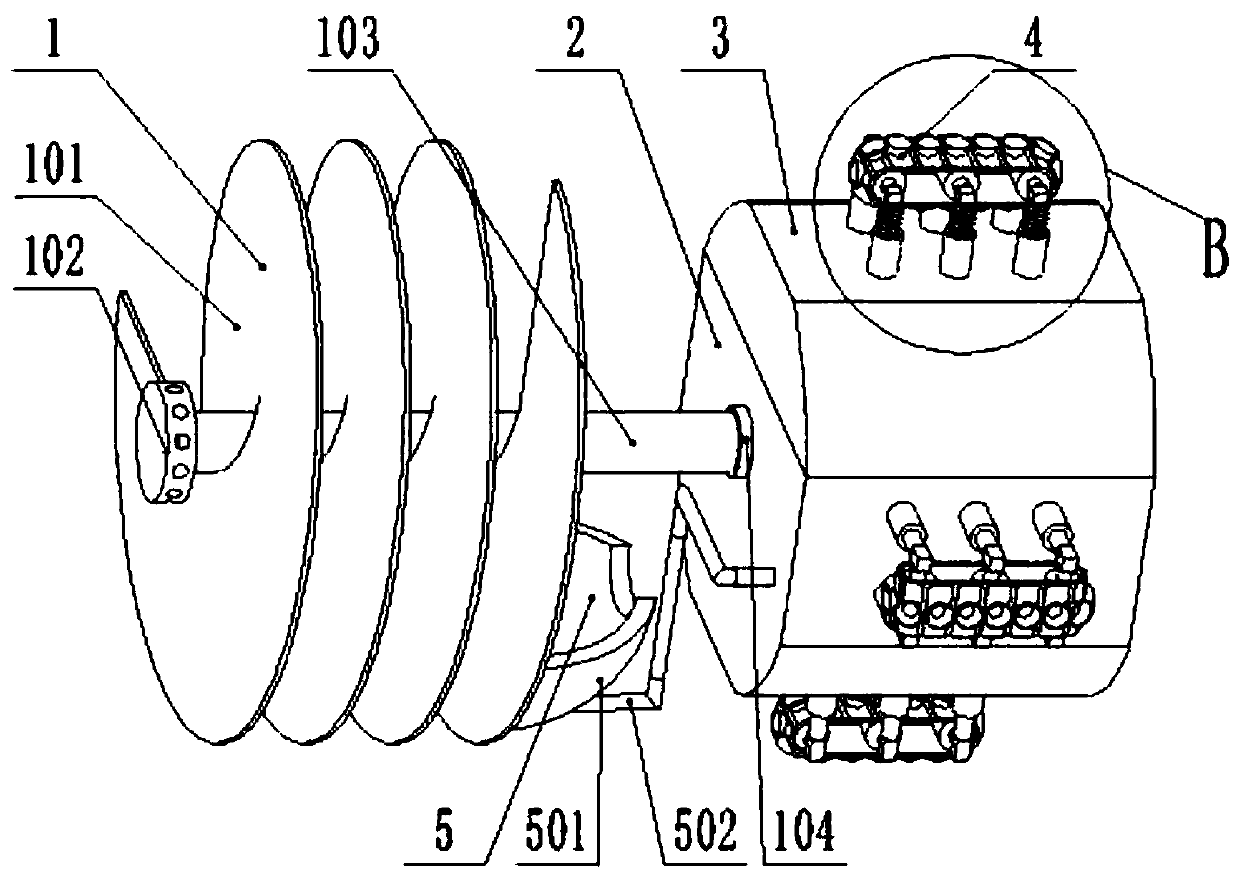

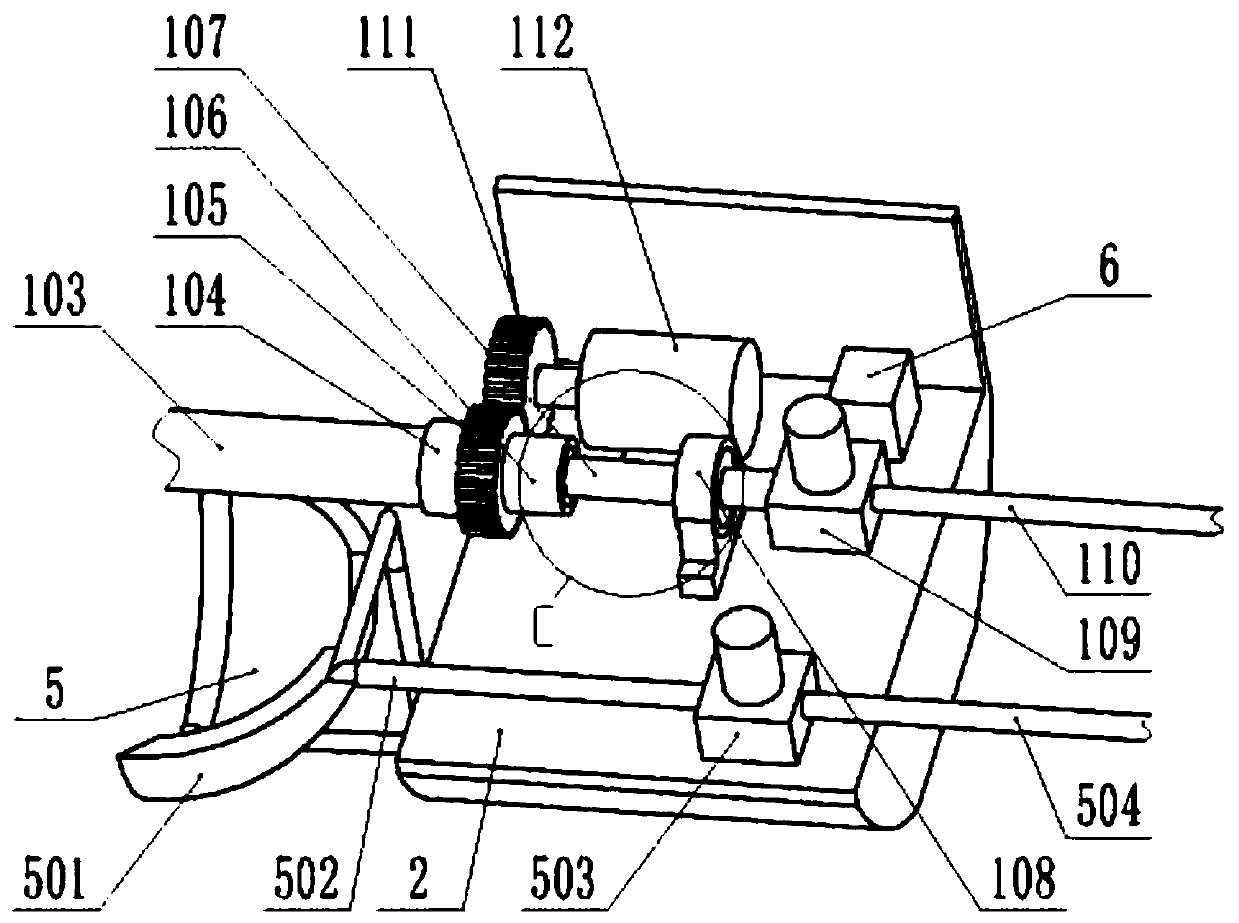

[0026]A pipeline cleaning robot is composed of a cleaning device 1, a lower box body 2, an upper box body 3, a walking device 4, a cleaning liquid recovery device 5 and a power control module 6. The cleaning device has a spiral cleaning blade 101, Cleaning nozzle 102, rotating hose 103, rotating hard pipe bearing 104, rotating hard pipe gear 105, rotating hard pipe 106, conveying water pipe 107, conveying water pipe fixing seat 108, cleaning liquid injection pump 109, cleaning liquid conveying drag pipe 110, motor Gear 111, motor 112 and water pipe sealing bearing 113, the cleaning nozzle 102 is installed on the front end of the rotating hose 103, the spiral cleaning blade 101 is installed on the front of the rotating hose 103, close to the cleaning nozzle 102, and the rotating hard pipe 106 The rotating hard pipe bearing 104 is connected with the lower box body 2, the rotating hose 103 is nested and fixedly connected with the rotating hard pipe 106, and the rotating hard pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com