Off-line programming track generation method and two-robot-collaborative assembly system based on method

A trajectory generation and offline programming technology, which is applied in the direction of program control manipulators, manipulators, manufacturing tools, etc., can solve the problems of unsuitable operation requirements of industrial robots, failure to realize offline programming, and lack of visual processing units, so as to improve programming efficiency and work Precision, Adaptability, and Scalable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

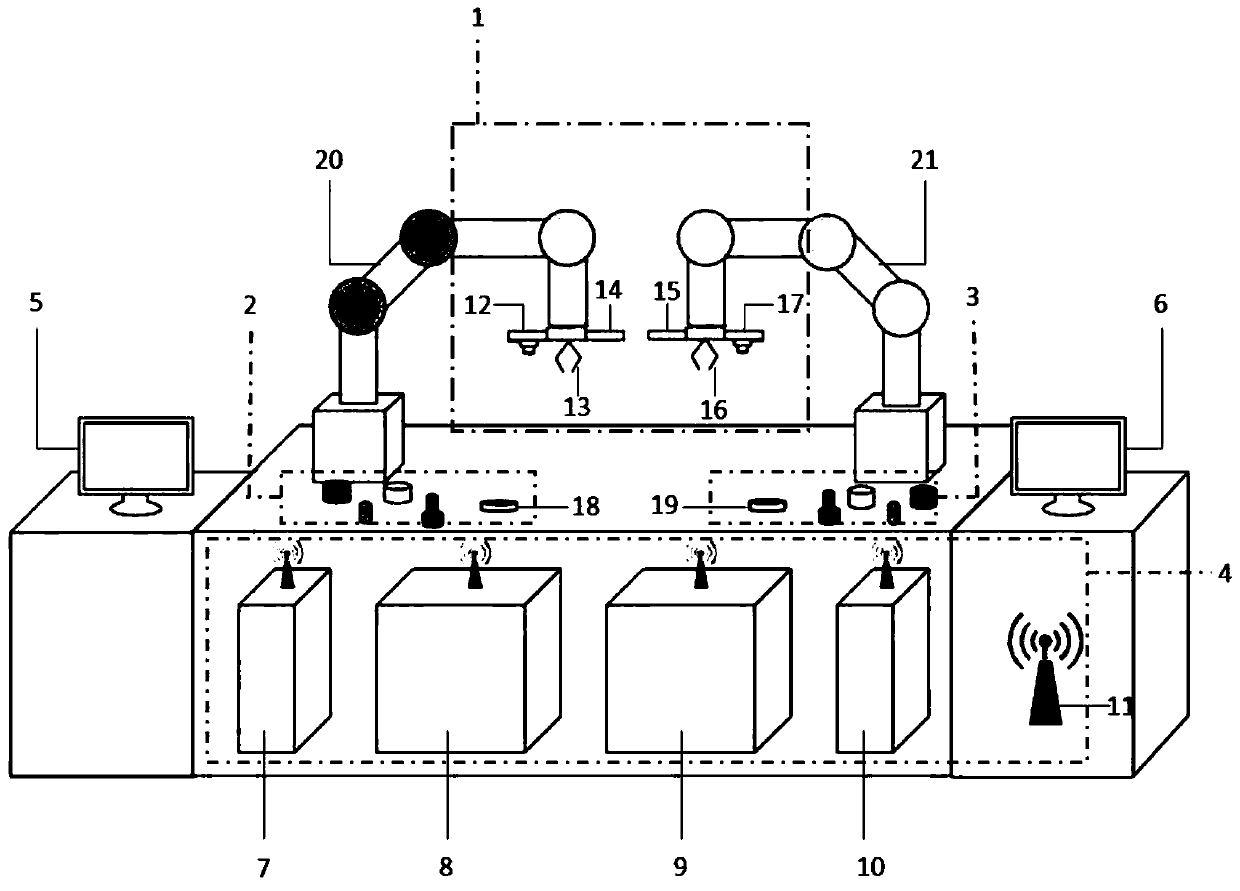

[0035] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings and examples.

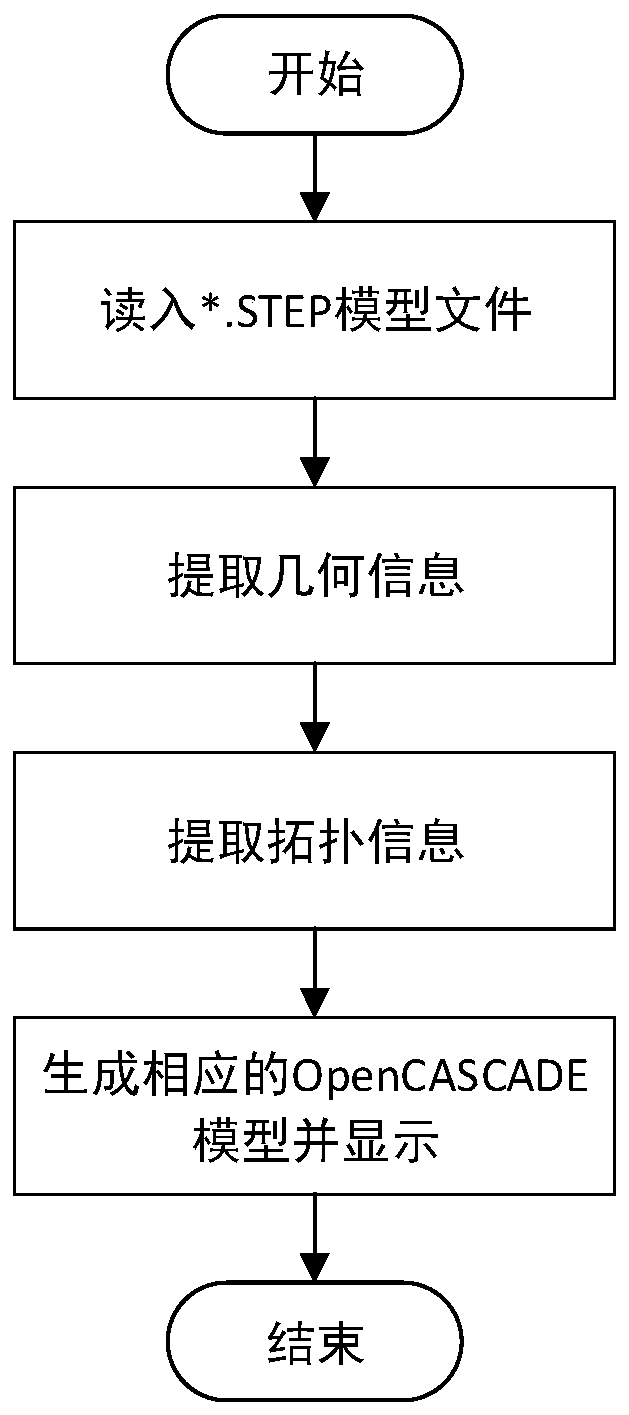

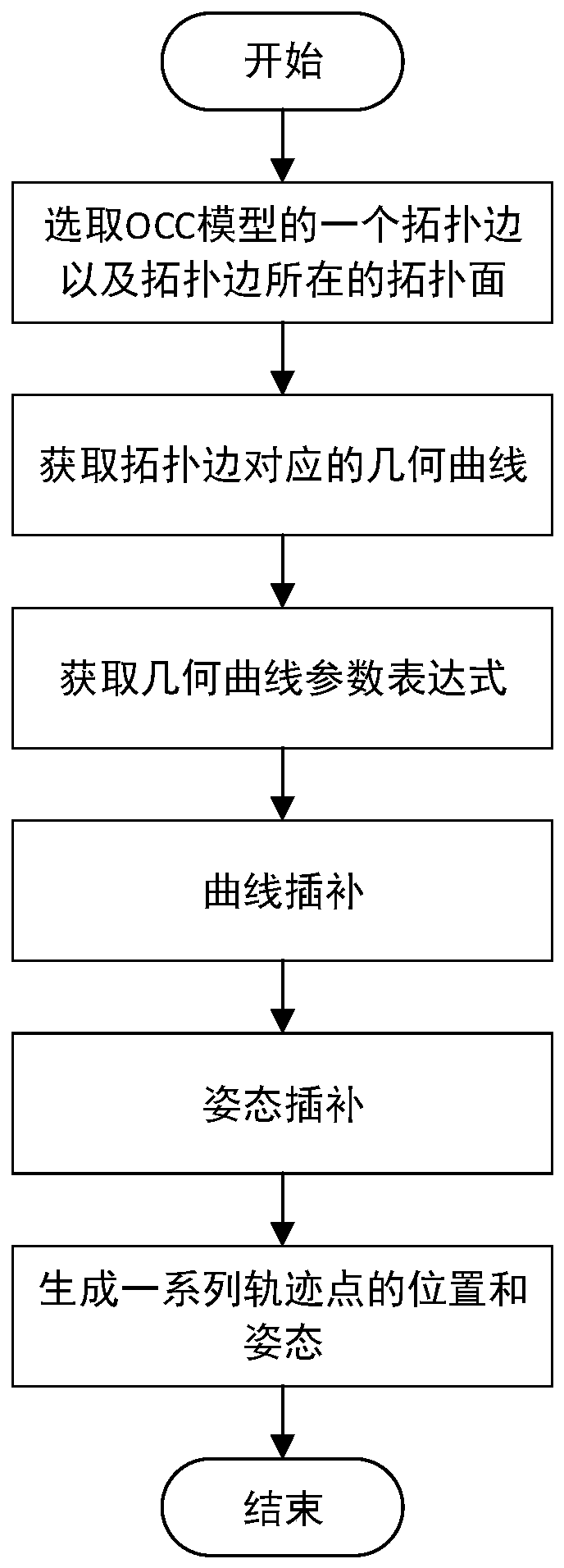

[0036] Such as figure 1 As shown, for a trajectory generation method based on offline programming proposed in this paper, the model reconstruction algorithm flow is introduced in detail in combination with an example of workpiece assembly. The specific steps are as follows:

[0037] (a) STEP model file reading, for the STEP model file saved in the form of strings, the effective information is extracted line by line and stored in the computer memory, and the corresponding character segmentation algorithm is selected according to the STEP file format for each line The string is split to extract valid entity information. The specific operation is, starting from the data segment of the STEP file, for each line of strings, extract the numbers between "#" and "=" to represent the entity number, and extract the strings between "=" and "(" to use...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap