Corrugated paper leading edge feeding digital inkjet all-in-one machine

A digital inkjet and all-in-one machine technology, applied in the direction of sending objects, thin material processing, printing, etc., can solve the problems that cannot overcome paper web deviation, printing deformation pattern embossing, kraft paper traces on paper surface, printing pattern deformation, etc. Achieve the effects of avoiding deformation, smooth paper surface and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

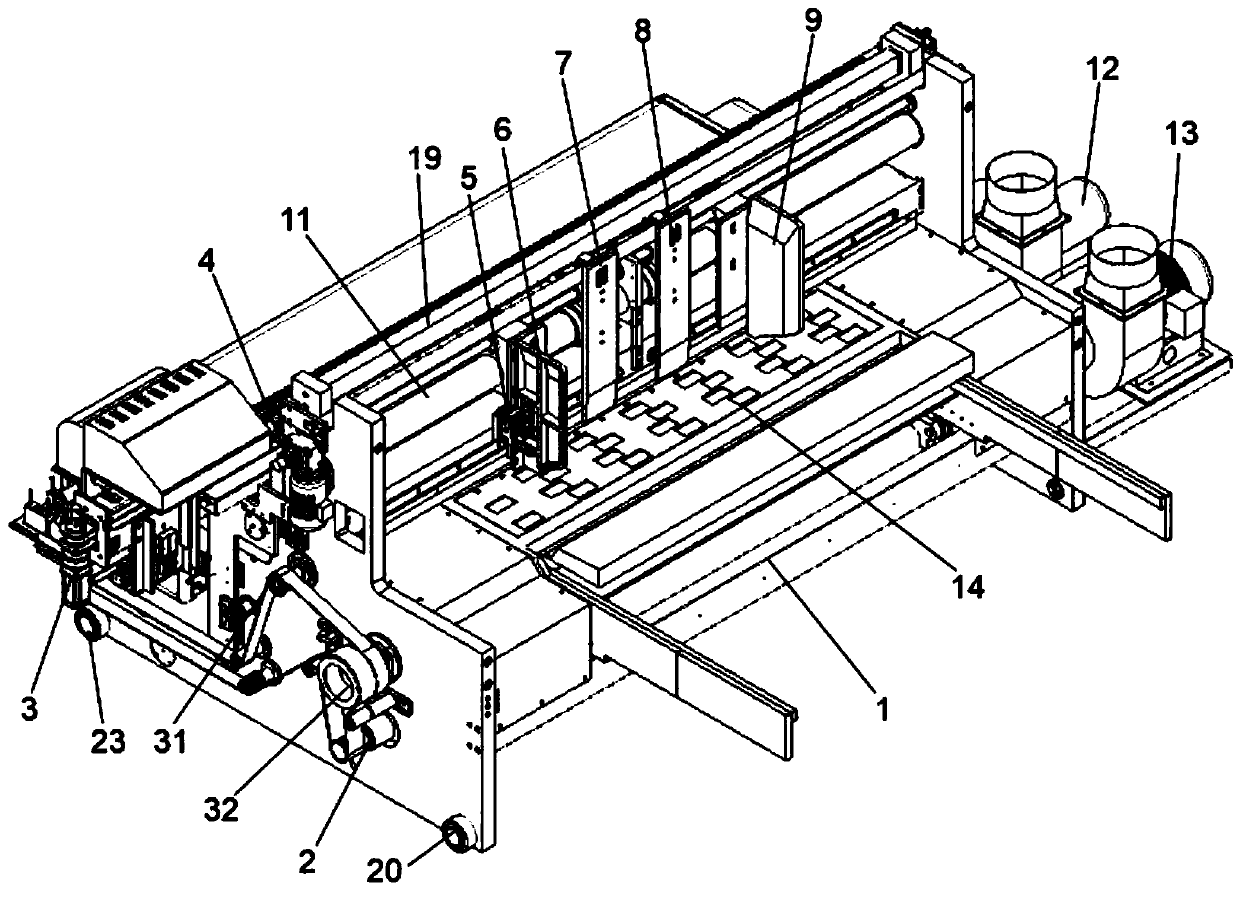

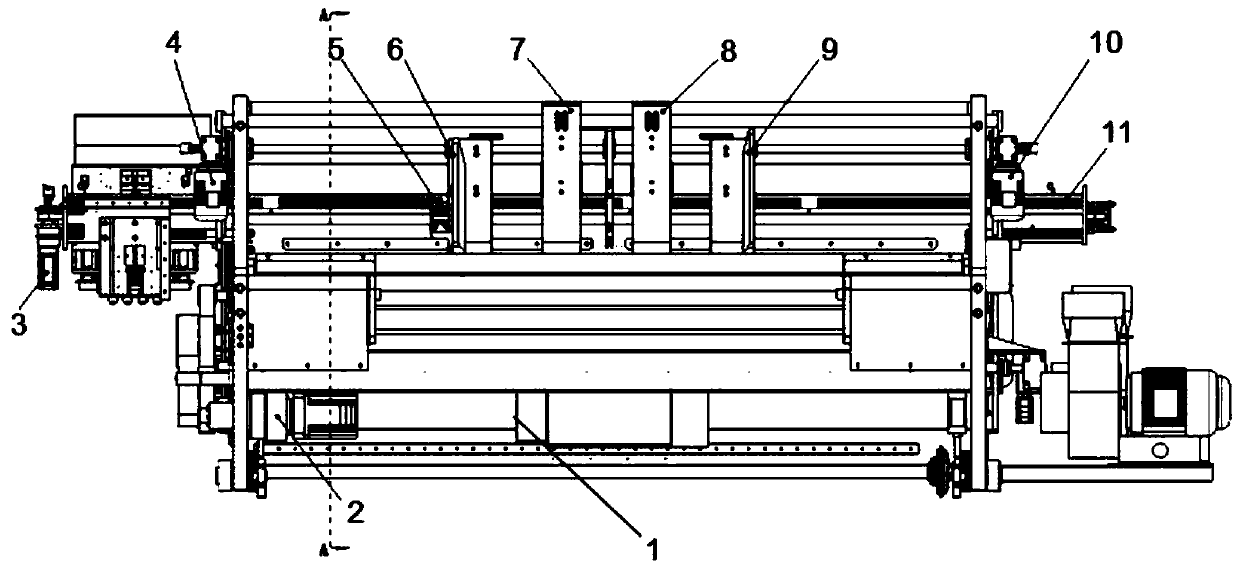

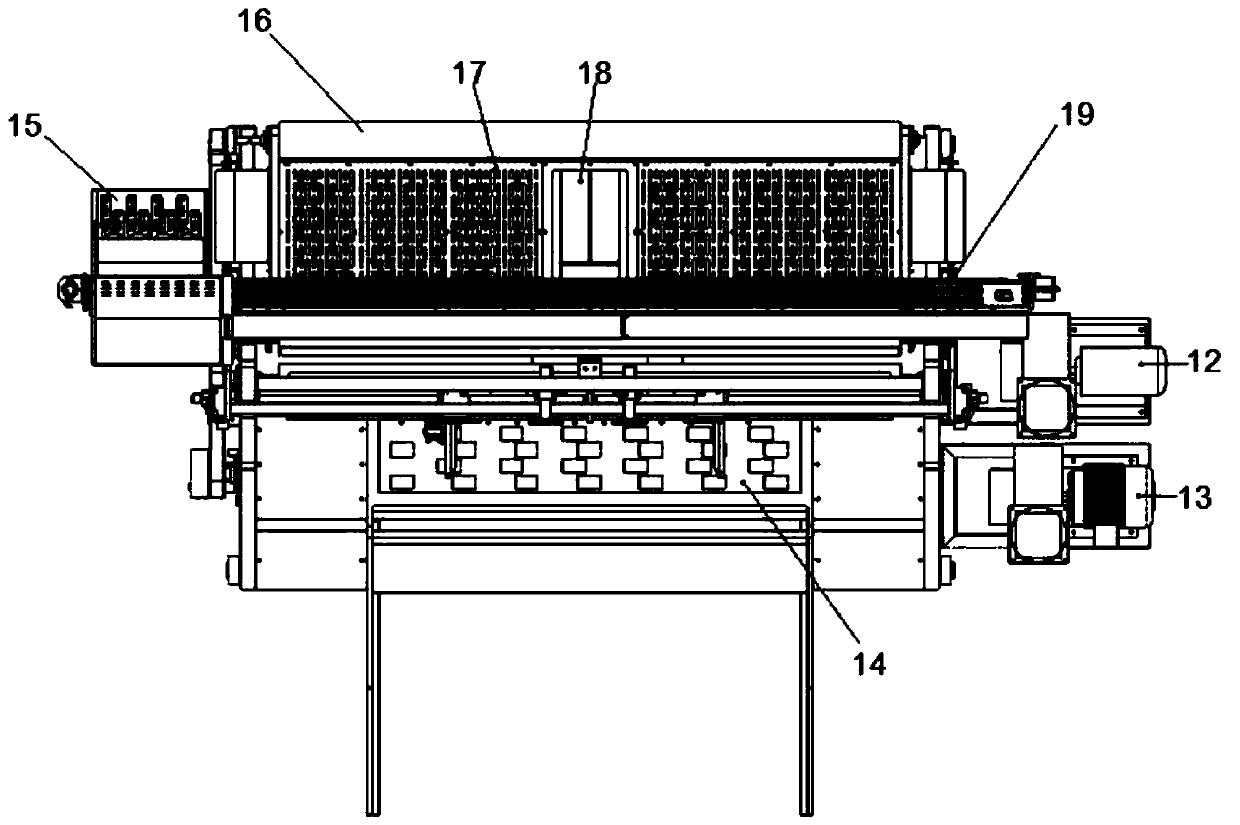

[0027] Embodiment: A digital inkjet all-in-one machine for corrugated paper leading edge feeding.

[0028] refer to Figure 1 to Figure 6 As shown, a digital inkjet all-in-one machine for feeding corrugated paper at the leading edge, including:

[0029] Rack 1;

[0030] The leading edge bellows paper feeding device installed on the frame 1, the leading edge bellows paper feeding device includes a leading edge adsorption fan 13, a leading edge paper feeding bellows 14, a paper pressing positioning mechanism, a driving pattern roller 31 and a passive pattern roller 36 , the front edge paper delivery bellows 14 are fixed on the front of the frame 1, the front edge suction fan 13 is installed on one side of the front edge paper delivery bellows 14, the front edge adsorption fan 13 and the front edge paper delivery bellows 14 They are connected by pipes, and the front edge paper feeding bellows 14 are provided with air holes on the surface, and the paper pressing positioning mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com