Heading machine dust-removing device

A technology of dust removal device and roadheader, which is applied in the direction of slitting machinery, earthwork drilling and mining, etc., which can solve the problems of reducing production efficiency, increasing roadway humidity, and rock and soil bonding into blocks, etc., to achieve low cost, reduce roadway dust, and save water. resource effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

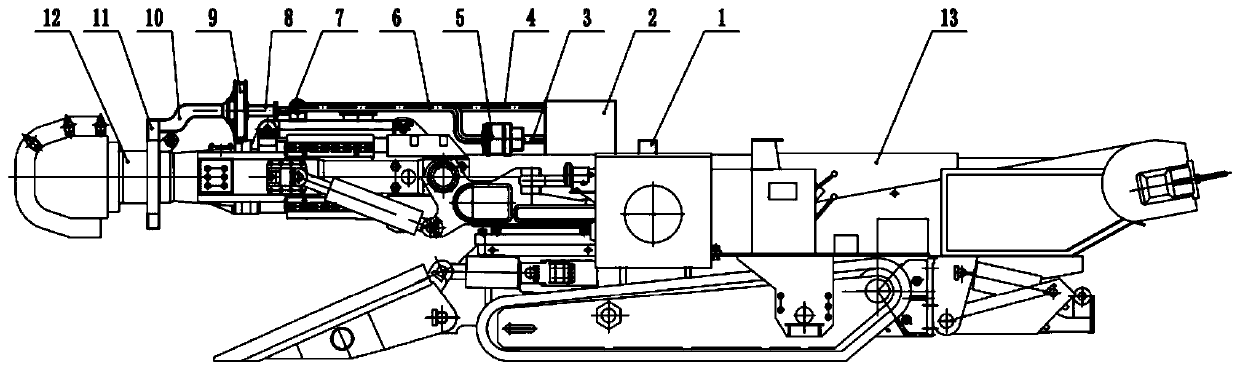

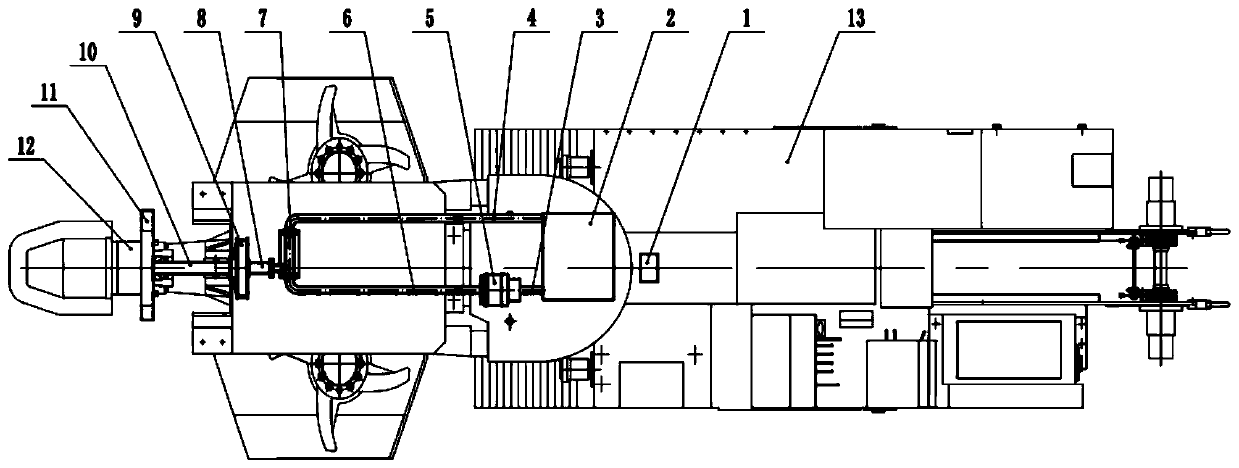

[0015] Attached below figure 1 ~ attached Figure 5 The present invention is described in detail below.

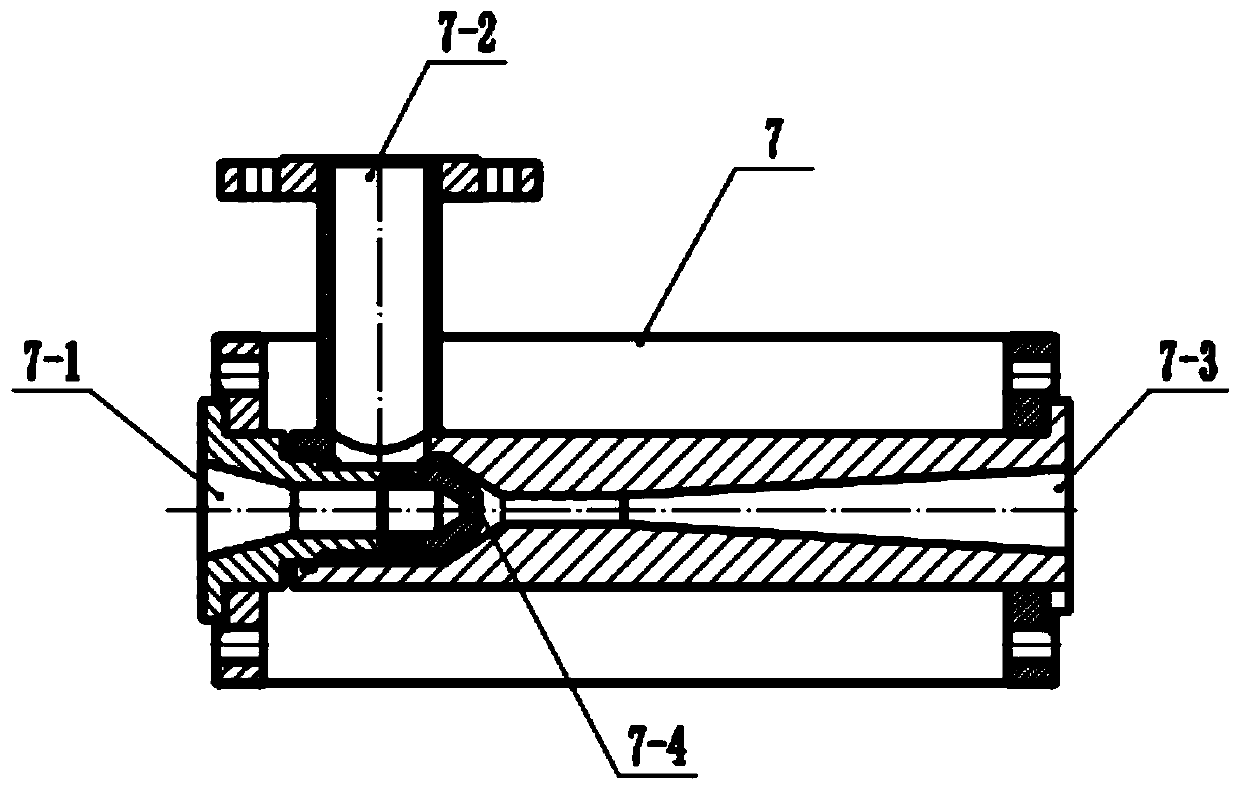

[0016] Such as Figure 1~5 As shown, the present invention includes a frame 13 and a cutting part 12. The cutting part 12 is in the shape of a cylinder that is thin at the front and thick at the back. The dust collector 11 is provided with four sets of dust suction holes 11-1 at the end close to the drill bit, and a dust collection pipe 10 is provided at the end far away from the drill bit. Connected; the upper end surface of the frame 13 is provided with an induced draft fan 9, an air pipe 8, a jet diverter 7, a water inlet pipe 6, an outlet pipe 4, a high-pressure water pump 5, a suction pipe 3, a sedimentation filter water tank 2 and The control box 1, the air inlet of the induced draft fan 9 are fixedly connected to the dust collection pipe 10, the air outlet is fixedly connected to the air pipe 8, and the jet diverter 7 includes an air inlet 7-2, a water inlet 7-1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com