A rice drying device

A drying device and technology for rice, applied in drying, drying machine, heating device and other directions, can solve the problems of easy scorching and blackening of rice, affecting the quality of rice, and insufficient drying effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

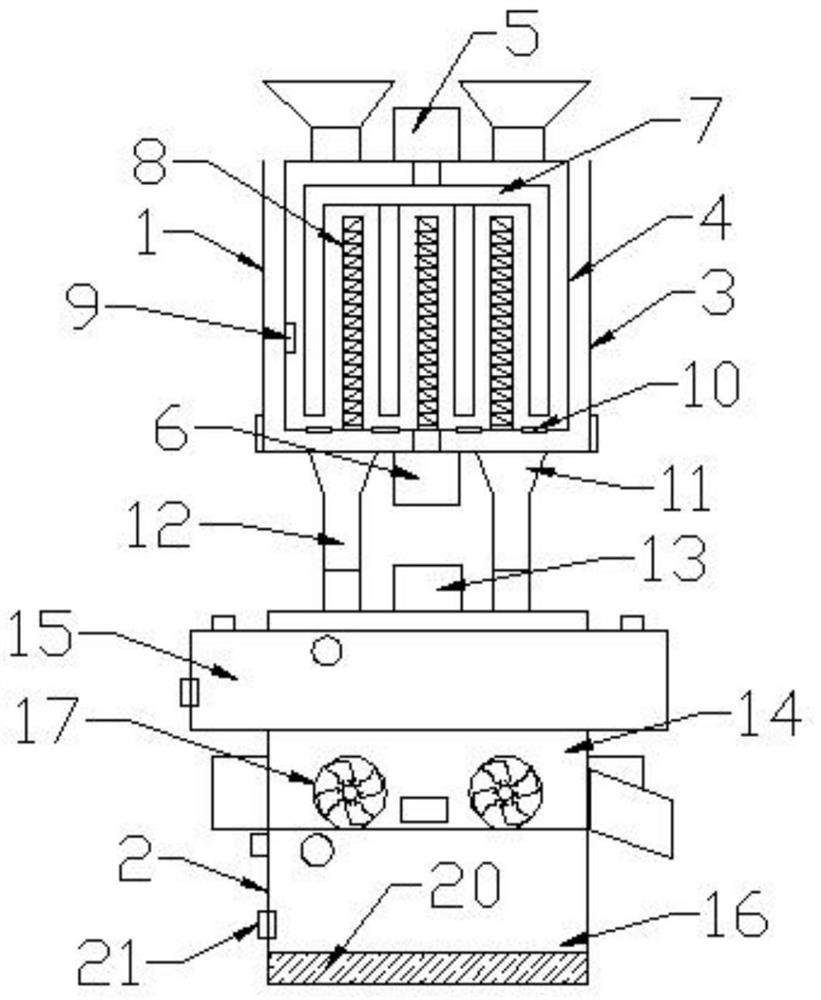

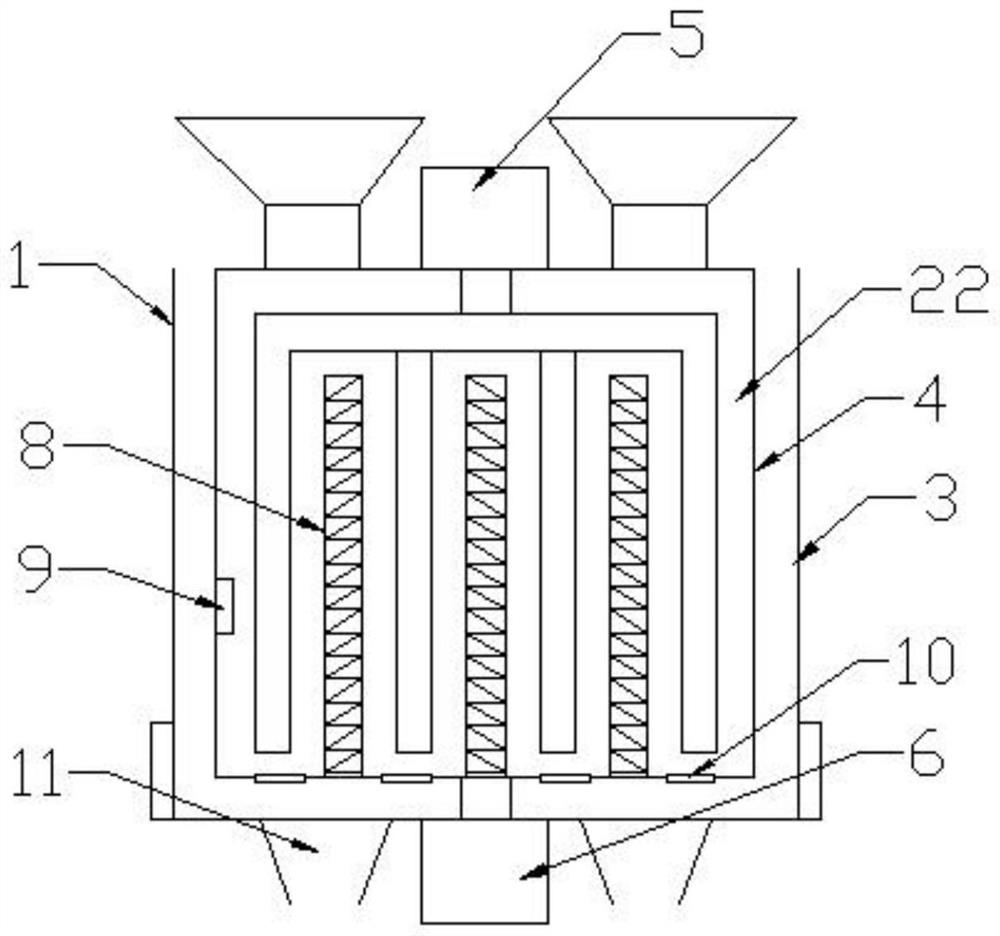

[0027] Such as figure 1 , figure 2 and Figure 5 Shown, a kind of rice drying device, comprises No. 1 drying device 1, No. 2 drying device 2, outer case 3 and inner case 4 in No. 1 drying device 1, the top of outer case 3 is open state, A No. 1 motor 5 is installed on the top of the inner box 4, and the output shaft of the No. 1 motor 5 is connected to the stirring element 7 inside the inner box 4. The stirring element 7 includes several stirring shafts 22, and several heating pipes 8 are arranged inside the inner box 4. , all heating tubes 8 and stirring shaft 22 are interlacedly arranged; the bottom of outer case 3 is provided with No. 2 motor 6, and the output shaft of No. 2 motor 6 passes through outer case 3 and is fixed on the bottom of inner case 4.

[0028] In the present embodiment, by setting the heating tube 8 in the inner box 4, the stirring member 7 is set at the end of the output shaft of the No. 1 motor 5, and the stirring shaft 22 in the stirring member 7 is...

Embodiment 2

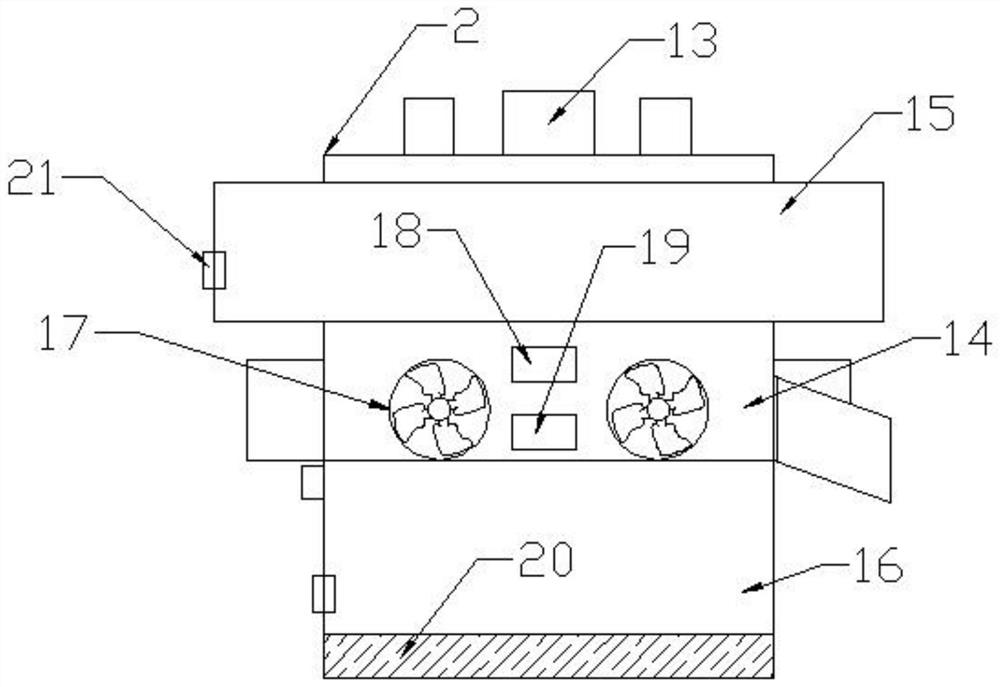

[0030] Such as figure 1 , image 3 and Figure 6 As shown, the No. 2 drying device 2 includes a drying bin 14, a No. 1 water tank 15 and a No. 2 water tank 16. The No. 1 water tank 15 is fixed on the periphery of the top of the drying bin 14, and the No. 2 water tank 16 is fixed on the drying bin 14. The bottom of the first water tank 15 and the bottom of the second water tank 16 are all provided with a heating base 20, and heating resistance wires 19 are all installed in the heating base 20.

[0031] In the present embodiment, by setting No. 1 water tank 15 and No. 2 water tank 16 in No. 2 drying device 2, the heating base 20 in No. 1 water tank 15 and No. 2 water tank 16 can be heated, so that No. 1 water tank 15 and No. 2 water tank can be heated. The water in the No. 1 water tank 16 is heated and boiled, so that the rice in the drying bin 14 is heated by steam. At the same time, water vapor will not enter the drying bin 14, and the moisture of the rice will not be increa...

Embodiment 3

[0033] Such as Figure 1-6 As shown, several fans 17 are installed on the outside of the bottom of the drying bin 14, and the air outlets of all fans 17 are all set towards the drying bin 14; the top of the drying bin 14 is equipped with No. The output shaft is connected to the central axis 23 in the drying chamber 14 through a coupling, and there are several mounting grooves outside the central axis 23, and stirring rods 24 are inserted in all mounting grooves, and all stirring rods 24 are connected to the mounting grooves. Corresponding installation holes are provided, and all stirring rods 24 are installed in the installation grooves by bolts and nuts, and several support rods 18 with different inclination angles are welded on all stirring rods 24; the bottom plate of the inner box 4 There are several discharge holes 10, and two discharge ports 11 are provided on the bottom plate of the outer box 3, and the two discharge ports 11 are connected to the feed port at the top of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com