A medium and low speed maglev vehicle suspension frame strength test bench

A technology of strength test and suspension frame, applied in the direction of railway vehicle testing, etc., can solve the problems of complex load frequency of the running mechanism, many people running, and great potential safety hazards, and achieves easy and economical operation of patch or patch replacement and other processing. The effect of site space and reduction of installation height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

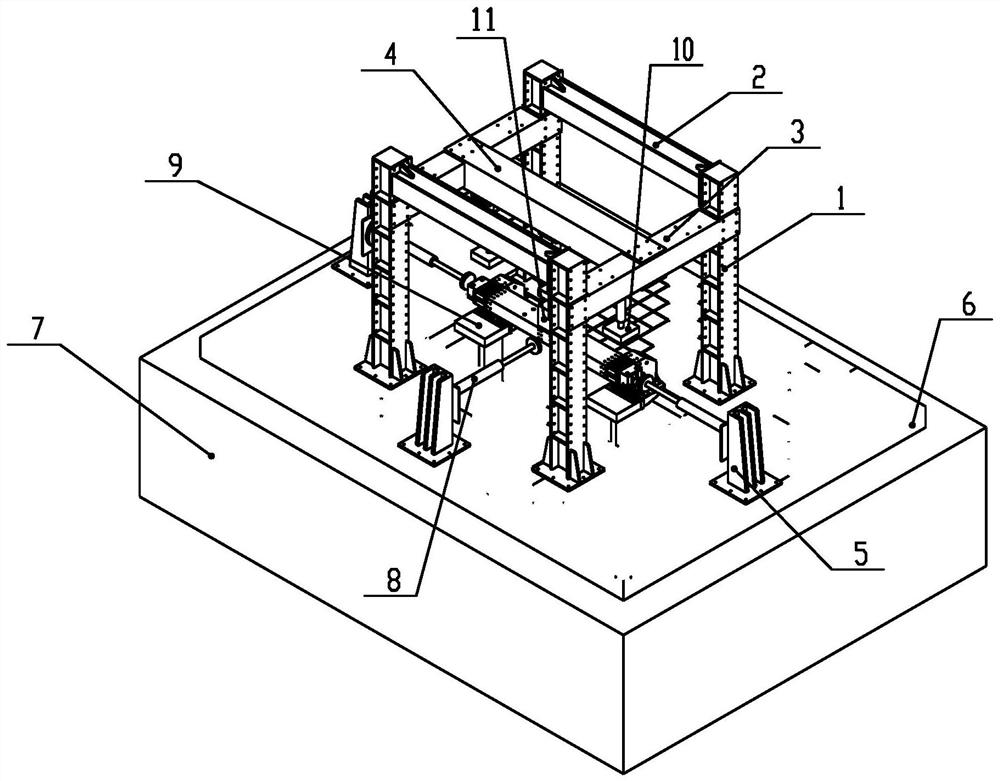

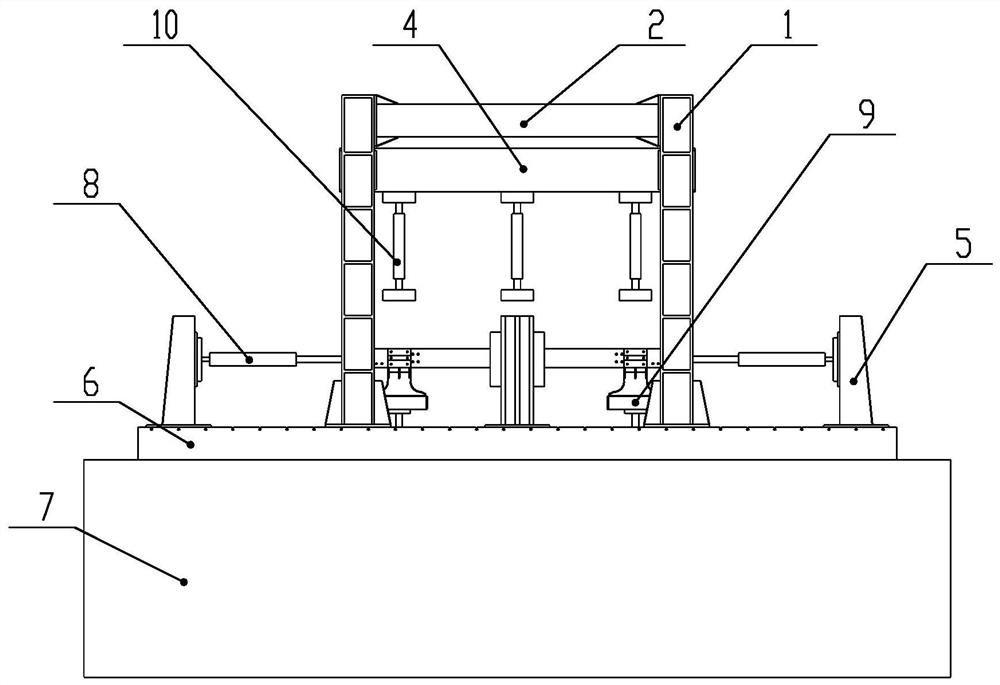

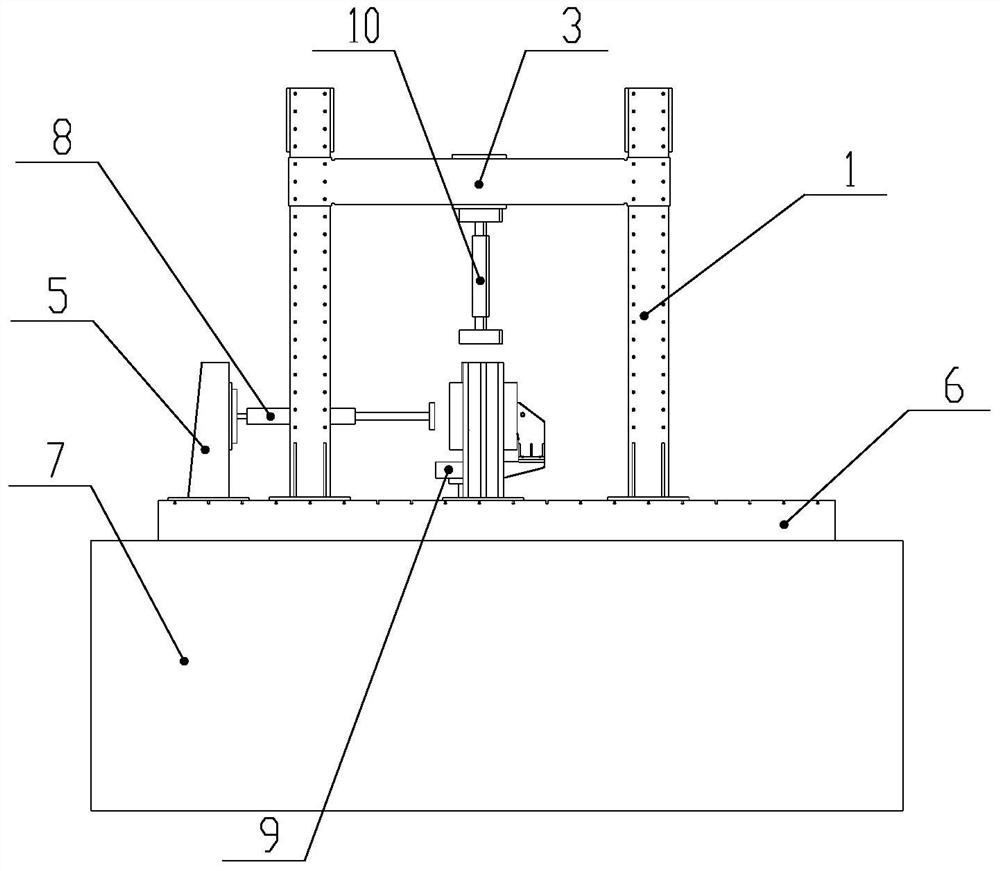

[0032] Please refer to figure 1, the present embodiment provides a medium-low speed maglev vehicle suspension frame strength test bench, which includes: load-bearing bracket 1, load-bearing bracket fixed beam, vertical load bearing beam 4, horizontal load bearing frame 5, T-slot platform 6, foundation 7 , the actuator 8, the displacement restraint assembly 10 and the suspension frame tooling connected to the suspension frame, wherein the fixed beam of the load-bearing bracket includes the first fixed beam 2 and the second fixed beam 3, and the suspension frame tooling includes the actuator 8 to facilitate the suspension The electromagnet replacement tooling 9 and the empty spring slide table replacement tooling 11 for loading the load on the frame, wherein the suspension frame is a frame body used for suspension of medium and low-speed maglev vehicles. Since the suspension frame is a left-right symmetrical structure, and its structure is decoupled , strength test can be carrie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com