A method for rapid detection of bacterial endotoxin

A bacterial endotoxin, rapid technology, applied in the direction of measuring devices, material stimulation analysis, instruments, etc., to achieve fast analysis speed, good reproducibility, and overcome the effect of coffee ring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

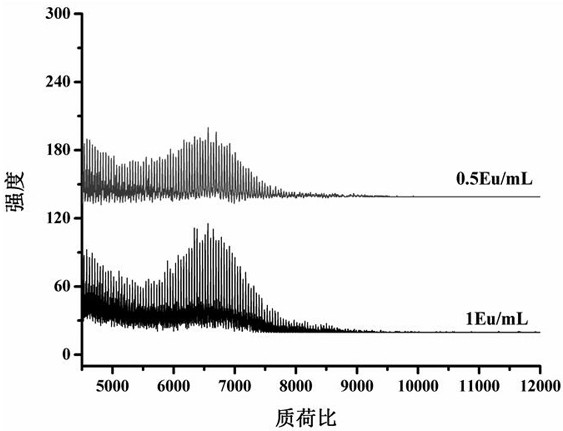

Examples

Embodiment 1

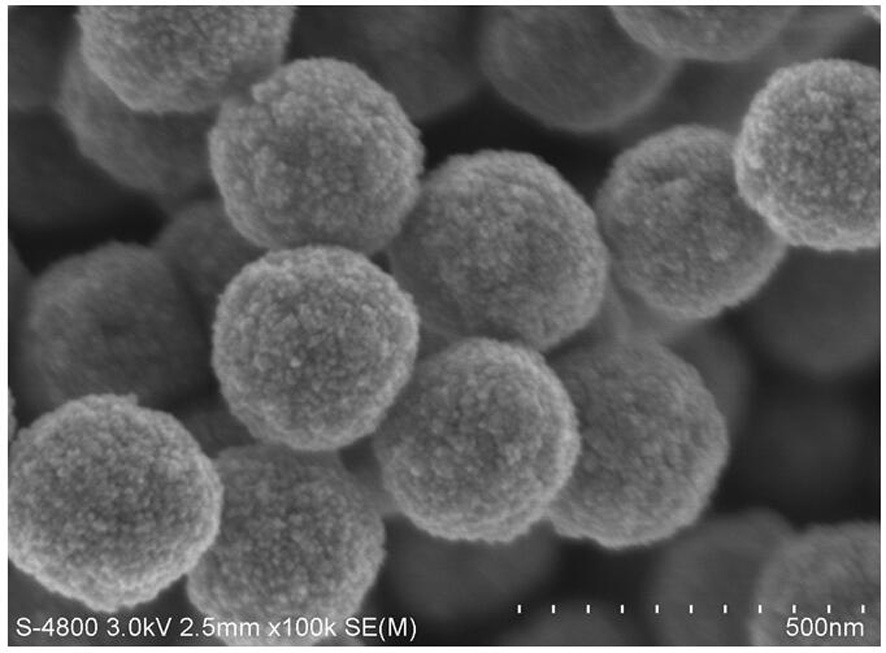

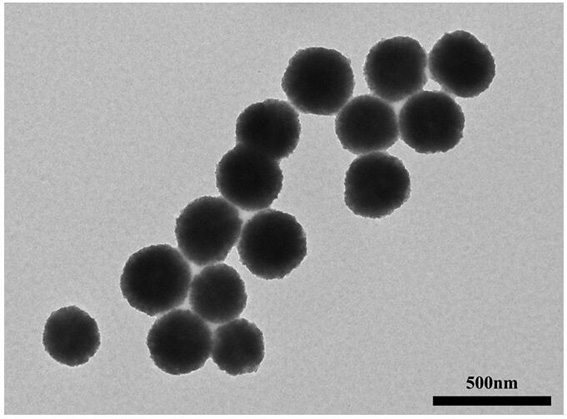

[0031] The preparation of zinc ferrite chitosan composite matrix comprises the following steps:

[0032] Step 1: Preparation of zinc ferrite: Weigh zinc oxide, sodium acetate, FeCl 3 ·6H 2 O and Na 3 Cit·2H 2 O was dissolved in ethylene glycol, and the resulting solution was transferred to a reaction kettle. The reaction kettle was placed in an oven at 200°C and reacted for 12 hours. The resulting magnetic product was washed with water and ethanol four times and then dried at room temperature, wherein zinc oxide, sodium acetate, FeCl 3 ·6H 2 O and Na 3 Cit·2H 2 The mass ratio of O is 1:7:3:0.01;

[0033] Step 2: Preparation of zinc ferrite-chitosan composite material: adding zinc ferrite and chitosan to acetic acid solvent, and stirring at constant temperature at 60° C. for 2 hours. The product was isolated using a magnet, washed with water and ethanol until near neutral. Vacuum drying the washed product at 50° C. to obtain a zinc ferrite chitosan composite material....

Embodiment 2

[0036] The preparation of zinc ferrite chitosan composite matrix comprises the following steps:

[0037] Step 1: Preparation of zinc ferrite: Weigh zinc oxide, sodium acetate, FeCl 3 ·6H 2 O and Na 3 Cit·2H 2 O was dissolved in ethylene glycol, and the resulting solution was transferred to a reaction kettle. The reaction kettle was placed in an oven at 200°C and reacted for 12 hours. The resulting magnetic product was washed with water and ethanol four times and then dried at room temperature, wherein zinc oxide, sodium acetate, FeCl 3 ·6H 2 O and Na 3 Cit·2H 2 The mass ratio of O is 1:8:4:0.03;

[0038] Step 2: Preparation of zinc ferrite-chitosan composite material: adding zinc ferrite and chitosan to acetic acid solvent, and stirring at constant temperature at 60° C. for 2 hours. The product was isolated using a magnet, washed with water and ethanol until near neutral. Vacuum drying the washed product at 50° C. to obtain a zinc ferrite chitosan composite material....

Embodiment 3

[0046] The preparation of zinc ferrite chitosan composite matrix comprises the following steps:

[0047] Step 1: Preparation of zinc ferrite: Weigh zinc oxide, sodium acetate, FeCl 3 ·6H 2 O and Na 3 Cit·2H 2 O was dissolved in ethylene glycol, and the resulting solution was transferred to a reaction kettle. The reaction kettle was placed in an oven at 200°C and reacted for 12 hours. The resulting magnetic product was washed with water and ethanol four times and then dried at room temperature, wherein zinc oxide, sodium acetate, FeCl 3 ·6H 2 O and Na 3 Cit·2H 2 The mass ratio of O is 1:9:5:0.02;

[0048] Step 2: Preparation of zinc ferrite-chitosan composite material: adding zinc ferrite and chitosan to acetic acid solvent, and stirring at constant temperature at 60° C. for 2 hours. The product was isolated using a magnet, washed with water and ethanol until near neutral. Vacuum drying the washed product at 50° C. to obtain a zinc ferrite chitosan composite material....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com