Method for producing gluconic acid through bioconversion of lignocellulose

A technology of lignocellulose and gluconic acid, which is applied in the field of bio-manufacturing and bio-refining of bio-based chemicals, can solve the problems of limited number of catalyst cycles, high catalyst consumption, increased production cost of gluconic acid products, etc. Separation and purification, low matrix cost, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

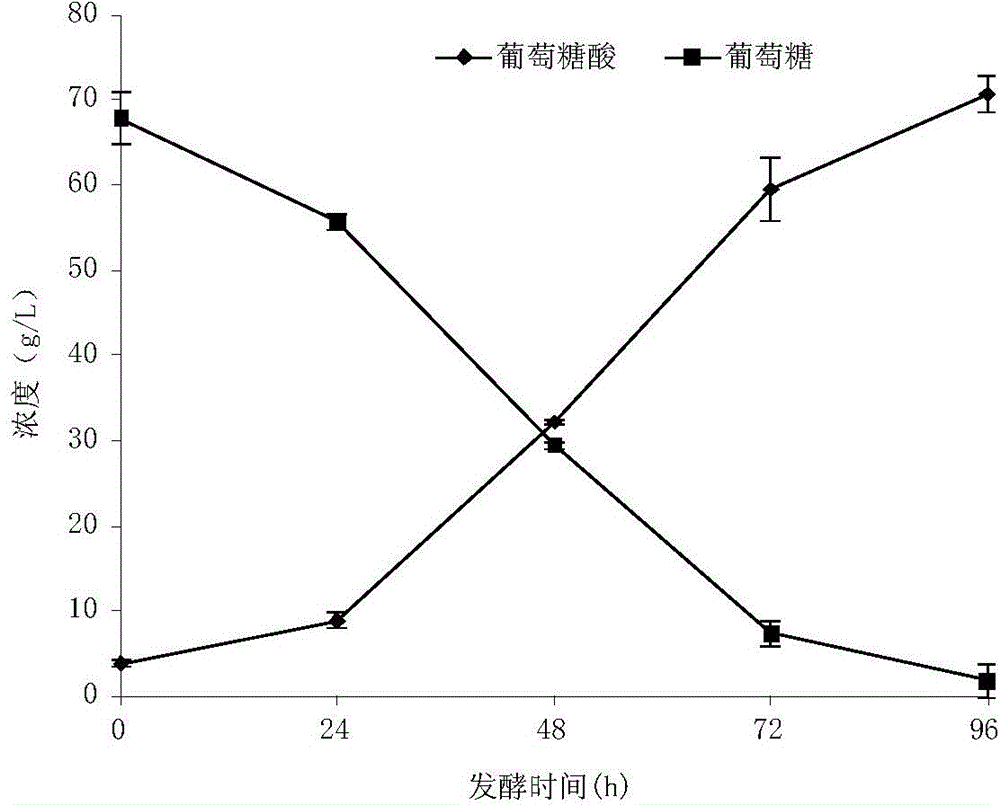

[0035] Mix the dried corn stalks with 5% (w / w) dilute sulfuric acid solution at a mass ratio of 2:1, pretreat for 3 minutes at 190°C and 1.2MPa; adjust the pH of the material after pretreatment To 5.5, insert the cultured biological detoxification strain Amorphotheca resinae ZN1 (CGMCC7452), and cultivate it statically for 7d under the condition of 25°C; then add the detoxified material into the reactor, and adjust the solid content to 25% ( w / w), adding cellulase (amount of 15FPU / g DM), saccharifying at 50°C and 150rpm for 48h, and controlling the pH at 4.8 with 5M sodium hydroxide during the saccharifying process. The concentration of glucose in the obtained corn stalk hydrolyzate was 71.42g / L. The corn stalk hydrolyzate was centrifuged at 10,000 rpm for 10 min and used as a culture medium, and was inserted into the Aspergillus niger (Aspergillus niger M276, purchased from Shanghai Institute of Industrial Microbiology Strain Collection Center) seed culture medium with 10% in...

Embodiment 2

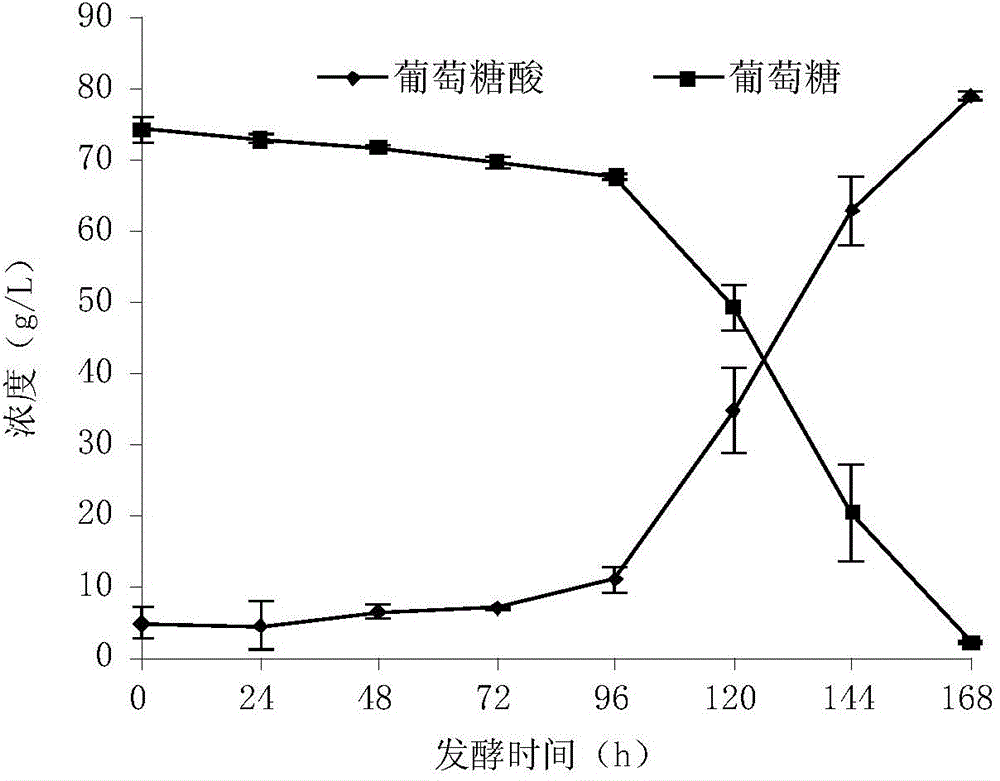

[0037] Mix the dried corn stalks with 5% (w / w) dilute sulfuric acid solution evenly at a mass ratio of 2:1, pretreat for 3 minutes at 190°C and 1.2MPa; add the pretreated materials directly Into the reactor, adjust the solid content to 25% (w / w), add cellulase (amount of 15FPU / gDM), saccharify at 50°C and 150rpm for 48h, use 5M sodium hydroxide to control pH during saccharification In 4.8. The concentration of glucose in the obtained corn stalk hydrolyzate was 75.36g / L. The corn stalk hydrolyzate was centrifuged at 10,000rpm for 10min and used as a culture medium, and was inserted into the seed culture medium of Aspergillus niger (Aspergillus niger M276, purchased from Shanghai Institute of Industrial Microbiology Strain Collection Center) with 10% inoculum, and fermented in a liquid state at 30°C for 168h. The rotating speed is 200rpm, the concentration of gluconic acid in the fermentation broth is 79.04g / L, and the conversion rate to glucose is 95%.

[0038] The cellulosic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com