Hole-tray vegetable cultivation substrate

A cultivation substrate and vegetable cultivation technology, which is applied in the field of plug vegetable cultivation substrates, can solve the problems of inappropriate physical properties, unfavorable crop growth, and low nutrient content, and achieve the effect of rich raw materials, favorable vegetable growth, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

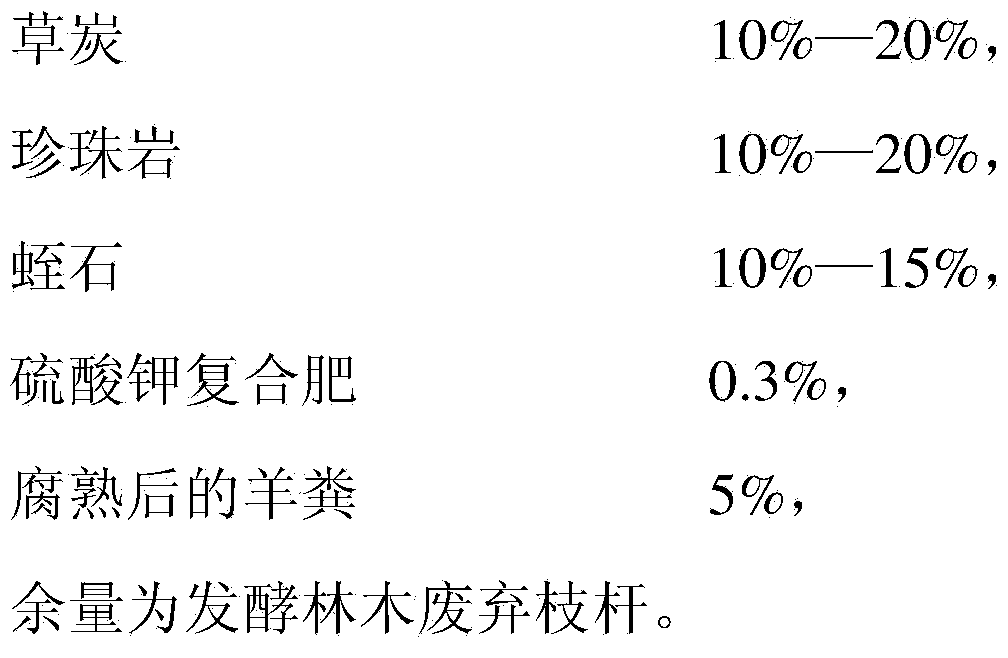

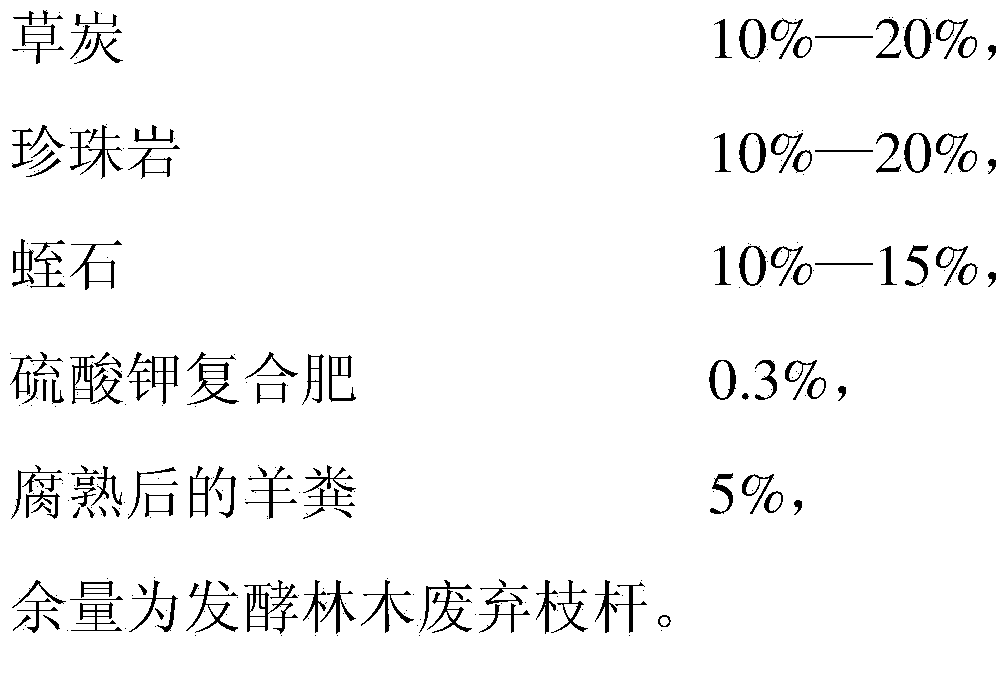

Method used

Image

Examples

Embodiment 1

[0015] Take forest trees (willows) with a particle size of 5-8 mm and crush 800 kg of branches, 200 kg of raw chicken manure, 1 kg of fermentation agent (Gymboree matrix nutrient soil fermentation aid), add water to adjust the water content to 60%, mix well and accumulate into The fermentation pile is fermented. The width of the fermentation pile is 2 meters, the length is 3 meters, and the height is 1.2 meters. When the temperature of the pile rises to 50°C, the pile starts to turn over. The temperature of the pile is controlled at 55-65°C, and the pile is turned every two days. After 90 days The fermentation is over.

[0016] Obtained respectively 60kg of fermented forest discarded branches, 10kg of peat, 15kg of perlite, 10kg of vermiculite, 5kg of decomposed sheep manure, and 0.3kg of potassium sulfate compound fertilizer were mixed evenly to obtain the cultivation substrate. The potassium sulfate compound fertilizer is Yanyangtian brand potassium sulfate compound fertiliz...

Embodiment 2

[0019] Take 800kg of crushed branches of forest trees with a particle size of 5-8mm, 200kg of raw chicken manure, 1kg of fermentation agent (HM fermentation agent), add water to adjust the water content to 60%, mix them and pile them up into a fermentation heap for fermentation. The width of the fermentation heap is 2 meters long, 3 meters long, and 1.2 meters high. Turn over when the temperature of the pile rises to 50°C, control the temperature of the pile at 55-65°C, turn over once every two days, and the fermentation ends after 90 days.

[0020] Take 55kg of fermented forest discarded branches, 15kg of peat, 15kg of perlite, 10kg of vermiculite, 5kg of decomposed sheep manure, and 0.3kg of potassium sulfate compound fertilizer, and mix them evenly to obtain the cultivation substrate. Among them, the potassium sulfate compound fertilizer is the Yanyangtian brand potassium sulfate compound fertilizer produced by Shandong Hongri Group.

[0021] Adopt above-mentioned cultivati...

Embodiment 3

[0023] Take 800kg of crushed branches of forest trees with a particle size of 5-8mm, 200kg of raw chicken manure, 1kg of fermentation agent (self-made fermentation agent), add water to adjust the water content to 60%, mix and pile up into a fermentation pile for fermentation, and the width of the fermentation pile 2 meters long, 3 meters long, and 1.2 meters high. Turn over when the temperature of the pile rises to 50°C, control the temperature of the pile at 55-65°C, turn over once every two days, and the fermentation ends after 90 days.

[0024] The above self-made fermentation agent is composed of 8 strains of bacteria and fungi, among which the fungi include the following 4 strains: Phanerochaete chrysosporium, Aspergillus niger, Trichoderma viride and Candida lipolytica (Candida lipolytica); bacteria include the following four strains: Bacillus subtilis, Azotobacter chroococcum, Bacillus megaterium, and Bacillus mucilaginosus

[0025] Take 50kg of fermented forest discard...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com