Accurate control system for automatic calibration of workpiece of numerically-controlled (NC) cutting machine

An automatic calibration and control system technology, which is applied in the general control system, control/regulation system, computer control, etc., can solve the problems of low efficiency, achieve good benefits, solve the effect of large deformation and precise cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

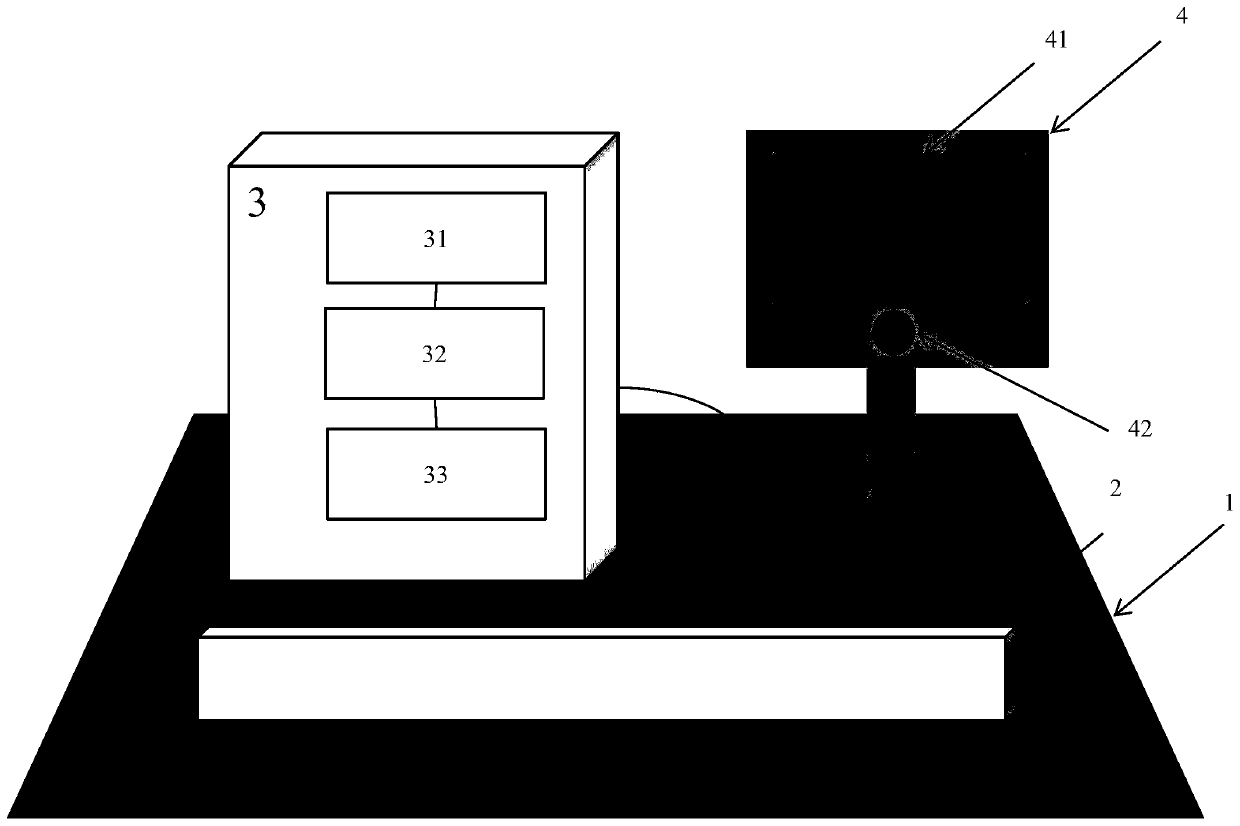

[0022] An automatic calibration system for a CNC cutting machine workpiece, characterized in that it includes a workbench, a milling cutter, a detection module, and a console. Wherein, the detection module is connected with the console and can be installed at any fixed position on the workbench. The detection module is composed of a three-dimensional laser scanner and a point laser ranging sensor connected in series. The console consists of a display and calibration buttons.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com