A chemical dangerous process risk intelligent monitoring method

A risk-intelligent and dangerous technology, applied in the field of intelligent risk monitoring of chemical hazardous processes, can solve the problems of manual inspection of chemical hazardous processes, large error in risk level assessment, and poor real-time risk control, so as to reduce implementation risks, improve efficiency, and reliable risks Evaluate the effectiveness of the program

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1 An intelligent monitoring method for chemically dangerous process risks:

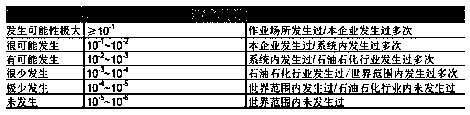

[0030] Acquire the historical data of all chemically hazardous process parameters in chemical production, and group the acquired data according to the type of chemically hazardous process. Group temperature data and a group of pressure data, use the K-means clustering algorithm on the grouped data to eliminate outlier data that deviates from the center of the cluster, and complete data purification. The main purpose of this step is to remove the artificial data in the training data. Error data, that is, complete the purification of the acquired data, as a sequence of historical process data.

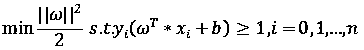

[0031] Then carry out mathematical modeling: using the SVM training method, the principle is: through the training process, the intrinsic feature modeling of a large amount of data is realized, that is, a large number of inputs with known risk levels are obtained, and a set of vectors wi is obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com